When freezing the keys, this icon will be constantly light. It will be off when unfreezing keys.

17

Temperature unit icon

When the control panel displays temperature, this icon will be constantly light.

18

Current unit icon

When the control panel displays current, this icon will be constantly light.

19

Time format icon

The unit is 12-hour format. “

”will be constantly light when it is forenoon.

“

” will be constantly light when it is afternoon

20

Frequency unit icon

It will be constantly light when the control panel displays frequency of the compressor.

21

ON/OFF and OK button

1.Long press “

” for 3S will power on or off the controller.

2.Press “

” to confirm the former operation when finishing the setting work.

22

Mode choice function/Function choice/Back function button

1.Mode choice function. Choose operation mode.

2.Function choice. Long press it for 3s to enter function setting in the main interface.(Clock setting,

Timing on and timing off setting)

3.Back to the previous menu. Long press it for 3s to back to previous menu in the function setting

interface. Top menu is the main interface.

23

Up

1.(Value increase)

2.Forward to the previous interface.

24

Down

1.(Value decrease)

2.Backward to the next interface.

16.1.1 Control panel operation description

1) ON/OFF

The first time to powered on the unit, operation panel displays “OFF”. Long press “

” for 3s, to unlock

“OFF” status and enter into standby status.

Power on: In the standby status, press “

” to enter mode choice function. Press “

” circularly

to choose one kind of “power on” mode, the mode icon will flicker at the moment. Press “

” to confirm

the power on mode. The unit will run as the chosen mode when the mode icon will be constantly light.

Power off: Press “

” in the main interface to enter mode choice function and the icon which indicate

the current mode will flicker. Press “

” circularly to choose power off mode,

“

” will flicker at this moment. Press “

” button to confirm the power off mode. By this time, “

”

will be constantly light and the unit stops.

2) Mode choice and temperature settings

Press “

” in the main interface to enter mode choice function. The “Mode” icon will flicker. Click

“

” circularly to choose a mode. The circulating order is

“

Cooling mode

”→“

Heating mode

”→

“

Water pump mode

”

→“

Power off mode

”

→

“

Cooling mode. The chosen mode will flicker. Press

“

”or “

” to increase/decrease the temperature in the chosen mode.

Press “

” to confirm power off mode and the set temperature. Mode icon will be constantly light and

the unit will run as the chosen mode. Press “

” or “

” in the main interface to increase/decrease the

temperature in the chosen mode.

3) Clock setting

Long press “

” for 3s to enter function interface. “

” clock icon will flicker. Press “

” to

enter clock setting function. “

” icon will be constantly light and the first 2 digits on nixie tube will flicker.

Press “

” or “

” to set minute. Press “

” when finish setting and “

” will be extinguished.

4) Timing setting

a. Timing on setting

①

Long press

“

”

for 3s to enter function interface. “

” clock icon will flicker. Press “

”again

to enter timing on function. “

” will flicker and press “

” to enter timing on setting.

49

Содержание SCV-100EA

Страница 1: ...SCV xxEA SERVICE MANUAL AIR COOLED MINI CHILLER UNIT AIR CONDITIONING...

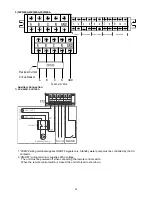

Страница 16: ...7 Wiring Diagram SCV 50EA SCV 70EA 14...

Страница 17: ...SCV 100EA 15...

Страница 18: ...SCV 120EA SCV 140EA SCV 160EA 16...

Страница 28: ...11 Water Pressure Drop SCV 50EA SCV 70EA SCV 100EA Heat exchanger pressure drop water side 26...

Страница 29: ...SCV 120EA SCV 140EA 27...

Страница 30: ...SCV 160EA 28...

Страница 46: ...t e s 1 2 3 3 To access the control panel open the door remove the screw 1 and screw 2 lift the door 3 44...

Страница 88: ...18 Optional Accessories No Name Specification Remark 1 Wired controller KJR 120F Customized 86...

Страница 91: ...Exploded view of unit SCV 50EA 22 7 22 6 22 5 22 4 22 2 22 1 22 3 89...

Страница 94: ...Exploded view of unit SCV 70EA 22 7 22 6 22 5 22 4 22 2 22 1 22 3 92...

Страница 97: ...Exploded view of unit SCV 100EA 25 1 25 2 25 3 25 6 25 7 25 4 25 5 25 9 25 8 95...

Страница 100: ...Exploded view of unit SCV 120EA 25 1 25 2 25 3 25 4 25 5 25 6 25 7 25 9 25 8 25 10 25 11 98...

Страница 103: ...Exploded view of unit SCV 140EA 25 1 25 2 25 3 25 4 25 5 25 6 25 7 25 9 25 8 25 10 25 11 101...

Страница 106: ...Exploded view of unit SCV 160EA 25 1 25 2 25 3 25 4 25 5 25 6 25 7 25 9 25 8 25 10 25 11 104...