Cut a new length of 1/16" music wire about 4" long. Reinstall the

cowl and insert the wire through the cowl and into the hole in the

needle valve and tighten the setscrew. Turn the needle all the way

in and make a mark on the wire, about 1/8" outside the side of the

cowl. Remove the wire from the needle valve and cowl and make

a 90

O

bend in the wire, at the mark. Trim the excess wire from the

bent end, leaving about 3/8" to grip on. Insert the wire back into

the cowl and needle valve and tighten the setscrew. You now have

a neat looking, perfectly aligned needle valve extension.

❑

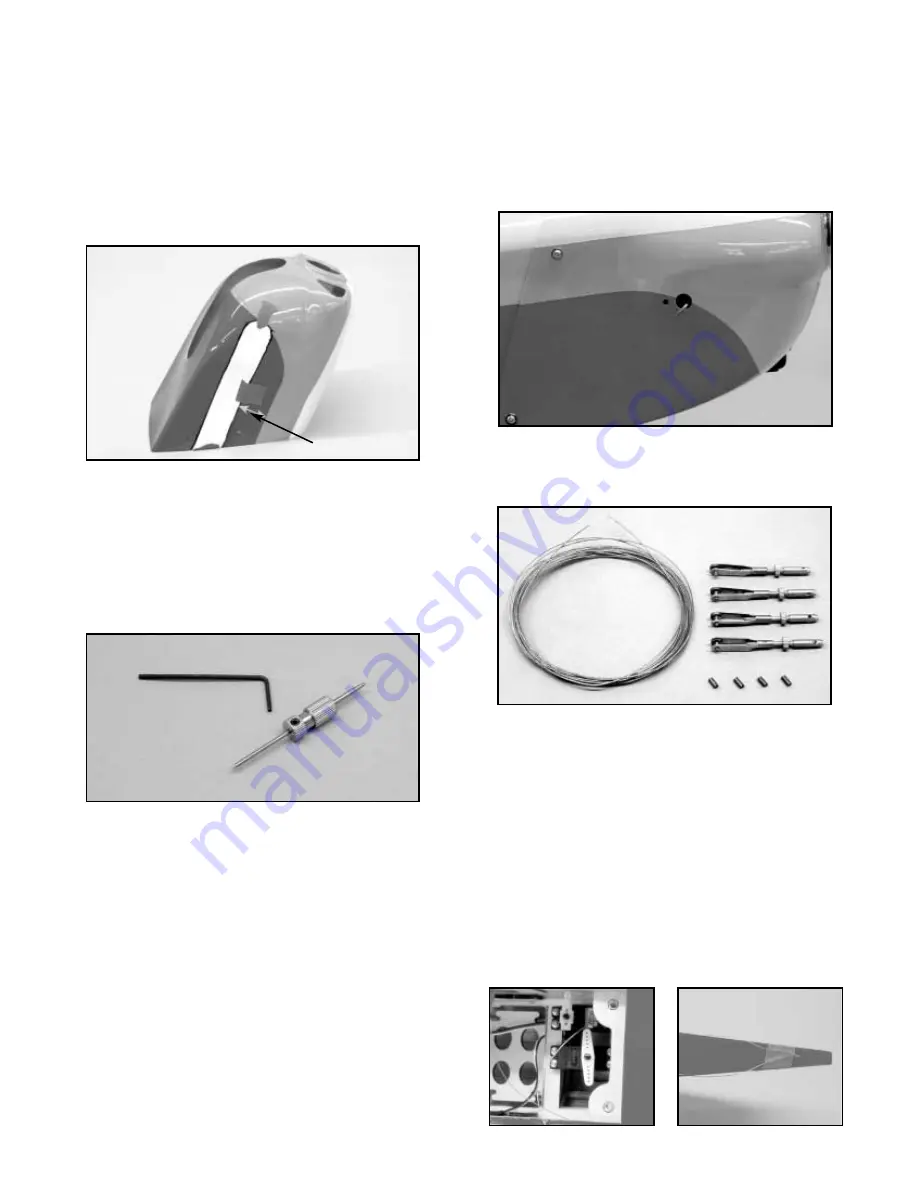

22) The rudder pull-pull system can now be installed. From the

kit contents, locate the 2 Steel Cables, 4 Swage Tubes, 4 Threaded

Rigging Couplers, and 4 Metal R/C links.

Mount the rudder servo in place using the screws and hardware

provided by the servo manufacturer. As previously mentioned, we

highly recommend using the Du-Bro super strength servo output

arms for the pull-pull rudder system.

Plug the servo into the

rudder outlet in the receiver, turn on your radio system and center

the servo, making sure that the transmitter rudder trim is in the

center position also, and install the servo output arm on the servo.

Turn off the radio system.

The pull-pull cables have been

provided in two equal lengths. Insert one of the cables into each

of the pull-pull exits located in the rear of the fuselage. Pass the

cables completely through the rear of the fuselage and up to the

rudder servo location. Keep pulling the cables forward until you

have about eight inches of cable remaining at the rear of the

fuselage. Tape the cables in place at the rear of the fuselage with

small pieces of masking tape to prevent the cable from slipping out

of the pull-pull exit tubes.

❑

20) Most engines will require another cut out in the cowl to clear

the exhaust system. The engine, shown in this manual, is the

YS-63S and the photos show how we cut the cowl to clear its

exhaust system. If you are using a different engine, then you will

have to use the same technique to create the required cowl

clearance hole for your particular engine.

For most engine

installations, there is more than an adequate amount of openings

provided in the cowling for cooling air to enter and exit. A rule of

thumb is that the exit area must be equal to or larger than cooling

air inlet. There should be at least 1/8" of clearance between the

cowling and any accessory such as muffler and/or carburetor.

❑

21) With the cowl now in place, you need to consider the

needle valve. Most engines come with a needle valve that has a

pre-drilled hole in its center and a setscrew. This is used when

attaching a needle valve extension. Our YS 4-stroke has just such

a needle valve assembly and the pre-drilled hole accepts 1/16"

dia. music wire. To locate the required needle valve extension hole

in the cowl, we put a short length of 1/16" dia. music wire into the

hole in the needle valve and tightened the setscrew to hold it

firmly.

The needle is then threaded back in place all the way into the

carburetor. Place a straight edge against the side of the fuselage

at the nose, intersecting the piece of wire and mark this point on

the wire. Remove the wire from the needle valve, cut the wire at

the point you just marked then sharpen the wire to a needlepoint.

Insert the wire back into the needle valve, tighten the setscrew and

install the cowl onto the fuselage. Turn the fuselage upside down

on your work surface and use a pair of needle nose pliers or

hemostats to begin turning the needle out. As the needle rotates

outward, the sharpened end of the wire will come into contact with

the inside surface of the cowl. Hold a scrap piece of wood against

the outside of the cowl, over the pointed wire, and continue

unthreading the needle valve until you get a definite dimple on the

outside of the cowl. When you see this mark, screw the needle

valve back into the carburetor and remove the cowl. Using the

dimple on the cowl for center, use a 3/32" dia. bit to drill through

the side of the cowl. Remove and discard the sharpened piece of

music wire from the needle valve. Make sure the needle valve

setscrew is aligned to allow access to it when the cowl is in place.

10

1-3/16”