.

KING KOBRA RC54 FUSELAGE CONSTRUCTION

Before beginning the fuselage, give some thought to your engine installation. The following instructions show an angled

installation with the nose gear bearing installed. The angle puts the engine muffler close to the fuselage and places the

needle valve of the engine at an ideal level in relation to the fuel tank. We recommend this location unless you have some

good reason for changing it.

On one of the prototypes the engine was mounted horizontally, which had the advantage of making it easy to run the tuned

pipe under the wing. This horizontal position is only possible if you are using a retract gear and won't have the nose gear

bearing in the way on the front of the firewall. A tuned pipe located on the side of the fuselage may require a nearly vertical

or vertical position to work out properly, depending on what shape headers are available for your engine and pipe. For

engine locations that put the needle valve above the recommended position it might be advisable to fit a fuel pump, such

as the Perry Micro-Oscillating Pump, to minimize fuel level change effects and obtain optimum engine operation. However,

the amount of variation from the ideal level is not very large so this may not be a problem. If a fuel pump is not used, a

muffler or pipe pressure tap to the tank is recommended.

The photo shows a horizontally mounted

engine with a Perry Micro Pump installed

in the King Kobra. Note that the firewall

had to be ground away a bit with a

Dremel tool to clear the pump mounted

on the back of the engine. Since the

firewall is 3 laminations thick, this was

no big deal, there was still plenty of

wood left to do the job. However, other

engines may be bulky enough to require

more room in the rear. We suggest here

an easy method of getting more

clearance behind the engine by

lengthening the cowling.

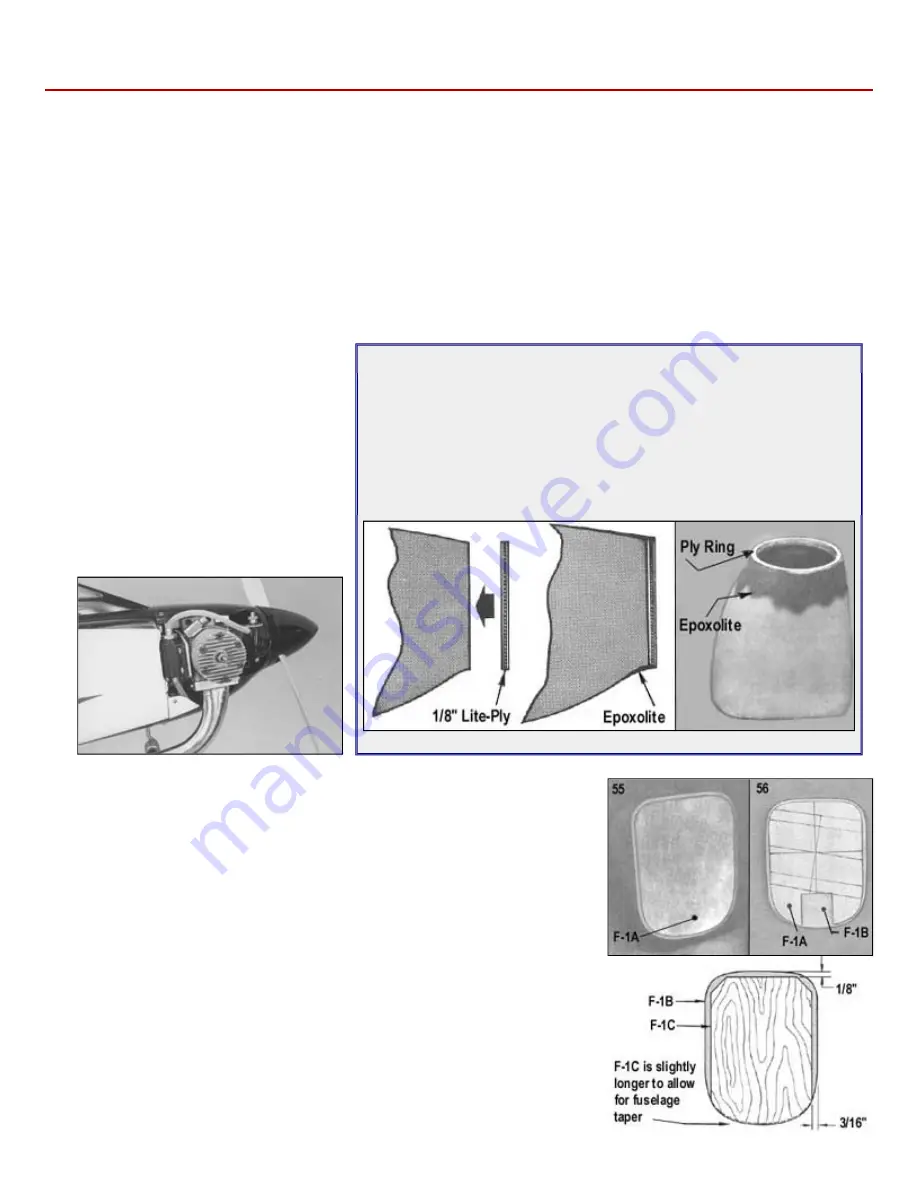

Optional Cowl Extension

The average .60 will not need this addition to the cowl. We show it here for

your information should extra room be required.

Sand the gloss off and roughen the plastic in the areas where the Sig

Epoxolite putty will be applied. (The putty will almost become an integral

part of the plastic if this procedure is followed.) Glue a plywood ring - in this

case it was one of 1/8" Lite Ply - to the front of the cowl. Fill the joint with

Epoxolite and blend it into the lines of the cowl.

55.

Sand any rough edges of F-1A, F-lB and F-lC. Fit F-lA inside the cowling.

56.

Draw layout lines on F-1A ot the proper width for the mounts and engine to be

used and at the angle chosen for mounting. Glue F-1A to the front of F-1B. Use

the cowl to check for correct position. If they should happen to be warped (a

congenital problem with plywood), clamp them together between two flat plates in

a vise while the glue is setting up.

NOTE: Leave the cut-out for the nose gear bearing in F-1A on for retract

versions.

57.

Glue F-1C to the back of F-1B with epoxy.

58.

Here's a handy way to fit the mounts to your engine. It temporarily turns them into

a one piece mount.

a. Layout guide lines on a piece of scrap 1/16" plywood of the proper width

and height.

b. Mark the top of the mounts on the sides so they can be accurately located.

c. Glue them in place on the scrap scab.