4-8

OP37/Pro Equipment Manual

Release 7/98

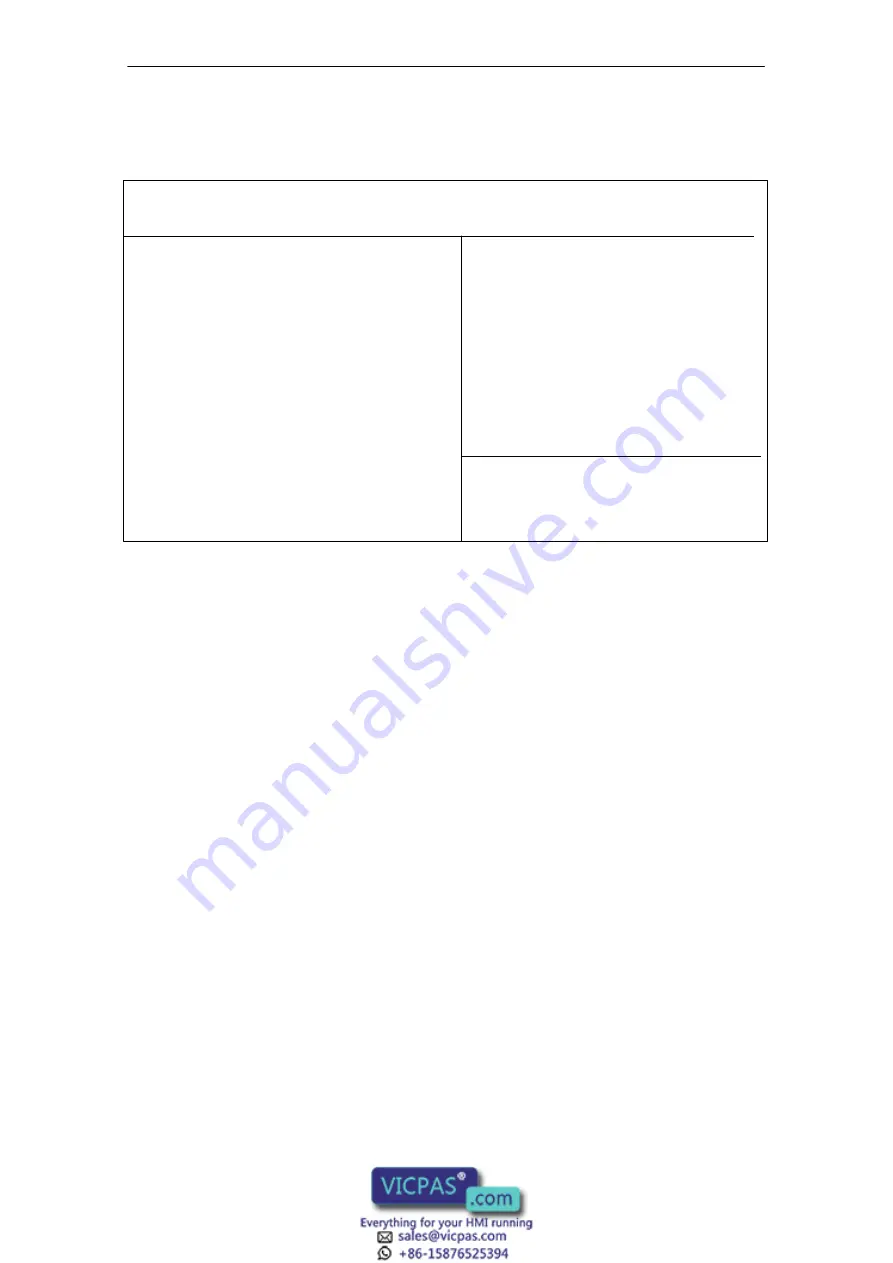

This screen defines the interface parameters for connecting peripherals.

ROM PCI/ISA BIOS (2A59F000)

CMOS SETUP UTILITY

AWARD SOFTWARE, INC.

IDE HDD Block Mode : Disabled

On-Chip Primary PCI IDE: Enabled

On-Chip Secondary PCI IDE: Disabled

IDE Primary Master PIO : Auto

IDE Primary Slave PIO : Auto

FDC Controller : Enabled

PCMCIA ATA HDD : Disabled

Parallel Port : LPT1/IRQ7

ASPC2 : Disabled

Matrix Keyboard : Disabled

PS/2 mouse : IRQ12

Serial 1 Address : COM1

Interrupt : IRQ4

Physical : TTY/V24 (IF1A)

Serial 2 Address : COM2

Interrupt : IRQ3

Physical : TTY/V24 (IF2)

Serial 3 Address : Disabled

Interrupt : Disabled

Physical : TTY/V24 (IF3)

Serial 4 Address : Disabled

Interrupt : Disabled

Physical : RS232 (IF4)

ESC: Quit

↑ ↓ → ←

:Select Item

F1 : Help PU/PD(+/– : Modify

F5 : Old Values (Shift)F2 : Color

F6 : Load BIOS Defaults

F7 : Load Setup Defaults

Figure 4-6

“Integrated Peripherals” screen

PCMCIA ATA HDD:

Has to be set to “enabled” when the OP is required to be booted from a

PCMCIA hard disk.

Parallel port:

The default setting is “LPT1/IRQ7” for connecting a printer to the parallel

interface. You can alter the setting for connecting various other devices

(e.g. a CD-ROM drive).

Possible parameters: Disabled, LPT1, EPP, ECP.

ASPC2:

The integrated ASPC2 for MPI/DP communication is deactivated when the

device is supplied. When you connect a SIMATIC S7 to the OP37/Pro, acti-

vate the ASPC2. Interrupt IRQ5 is assigned for this purpose. The requisite

driver is installed with the ProTool/Pro runtime software.

Serial 1 through Serial 4:

Here you perform the settings for the external interfaces on the rear panel

of the OP. The default settings correspond to the assignment of the

SIMATIC HMI OP family as supplied.

Interface IF4 is used internally.

Integrated

Peripherals

User-Specific Settings

Содержание SIMATIC HMI OP37/Pro

Страница 6: ...iv OP37 Pro Equipment Manual Release 7 98 Preface ...

Страница 8: ...6 10 OP37 Pro Equipment Manual Release 7 98 Servicing Maintenance ...

Страница 26: ...3 8 OP37 Pro Equipment Manual Release 7 98 Electrical Installation ...

Страница 54: ...6 10 OP37 Pro Equipment Manual Release 7 98 Servicing Maintenance ...

Страница 60: ...A 6 OP37 Pro Equipment Manual Release 7 98 Technical Data ...

Страница 72: ...Glossary 2 OP37 Pro Equipment Manual Release 7 98 Glos ...