Siemens Building Technologies

CM2N4625E / 02.1999

Landis & Staefa Division

3/10

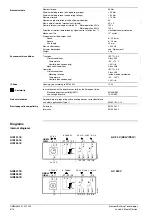

The illustration below shows the adjustable switching values for auxiliary switches A and

B in relation to the rotational angle.

Mounting position for

shaft adapter/position

indicator

Actuator scale:

Clockwise

Setting increments: 5°

Switching hysteresis: 2°

Adjustment span for

switches A and B

Actuator scale:

Counter clockwise

Setting position for

shaft adapter/position

indicator

A

B

-2,5° 0°

10°

20°

30°

70°

80°

90° 92,5°

+2,5°

0°

10°

20°

30°

70°

80°

46

36

D

0

1

92,5° 90°

80°

70°

60°

20°

10°

-2,5°

+2,5°

90°

0°

80

70

60

50

B

90

Aux Switch

Adjustment

20

30

40

10

20

40

A

70

46

3

7

Z

0

7

The setting shafts for the auxiliary switches turn together with the actuator. The scales

are valid only for the zero position of the actuator (clockwise movement).

Robust, lightweight all metal housing made from aluminum diecast which guarantees a

long actuator life even under extreme ambient conditions.

Maintenance-free and noise-free gear train with stall and overload protection for the life

of the actuator.

The actuator has a factory setting of + 2,5° which ensures a tight close-off for the air

dampers.

You can manually adjust the actuator by pushing the button "PUSH".

The actuator can be fastened to shafts with various diameters and in various shapes

(square, round) using just one screw due to the L&G patented mounting.

Insert the shaft adapter from either side into the opening for the shaft adapter depending

on the damper shaft length. For short shafts, the shaft adapter is on the duct side.

The shaft adapter coupling and the shaft holding are coupled via double-sided gearing.

The limitation of the rotational angle can be adjusted in the span of 0...90° in increments

of 5°.

A metal strip with bolt serves to fasten the actuator on the opposite side of the shaft

holding.

All actuators come with pre-wired 0.9 m long connection cables.

For supplementary functions, the auxiliary switches A and B can be adjusted on the

actuator front, below the opening for the shaft adapter.

A potentiometer has been integrated as positioner for the electrical position indication of

the damper position.

Adjustable auxiliary switch

(type-specific)

Note

Mechanical design

Basic components

Housing

Gear train

Actuator factory setting

Manual adjustment

Self-centering shaft

adapter

Mechanical limitation of

the rotational angle

Mounting bracket

Electrical connection

Type-specific elements

Auxiliary switches

Potentiometer for

position indication