Gamma

instabus

Technical product information

June 2014

Gamma arina touch sensor

Touch sensor, single

UP201/x2, without status LED and with orientation LED

5WG1 201-2DBx2

UP201/x3, with status LED and orientation LED

5WG1 201-2DBx3

Touch sensor, double

UP202/x2, without status LED and with orientation LED

5WG1 202-2DBx2

UP202/x3, with status LED and orientation LED

5WG1 202-2DBx3

Touch sensor, quadruple UP203/x2, without status LED and with orientation LED

5WG1 203-2DBx2

UP203/x3, with status LED and orientation LED

5WG1 203-2DBx3

UP203/x4, with status LED, orientation LED, scene controller and room temperature sensor

5WG1 203-2DBx4

UP203/x5, with status LED, orientation LED, scene controller, and IR receiver decoder

5WG1 203-2DBx5

UP 20x, UP 28x/3 and UP 28x/5

Technical product information

Siemens Building Technologies

Subject to change without further notice

Update: http://www.siemens.com/gamma

2.16.1.13/1

Product

Touch sensor, single

Touch sensor, double

Touch sensor, quadruple

without status LED and with ori-

entation LED

ivory white

5WG1 201-2DB12

5WG1 202-2DB12

5WG1 203-2DB12

champagne

5WG1 201-2DB32

5WG1 202-2DB32

5WG1 203-2DB32

with status LED and orientation

LED

ivory white

5WG1 201-2DB13

5WG1 202-2DB13

5WG1 203-2DB13

champagne

5WG1 201-2DB33

5WG1 202-2DB33

5WG1 203-2DB33

with status LED, orientation LED,

scene controller, and room

temperature sensor

ivory white

5WG1 203-2DB14

champagne

5WG1 203-2DB34

with status LED, orientation LED,

scene controller and IR receiver

decoder

ivory white

5WG1 203-2DB15

champagne

5WG1 203-2DB35

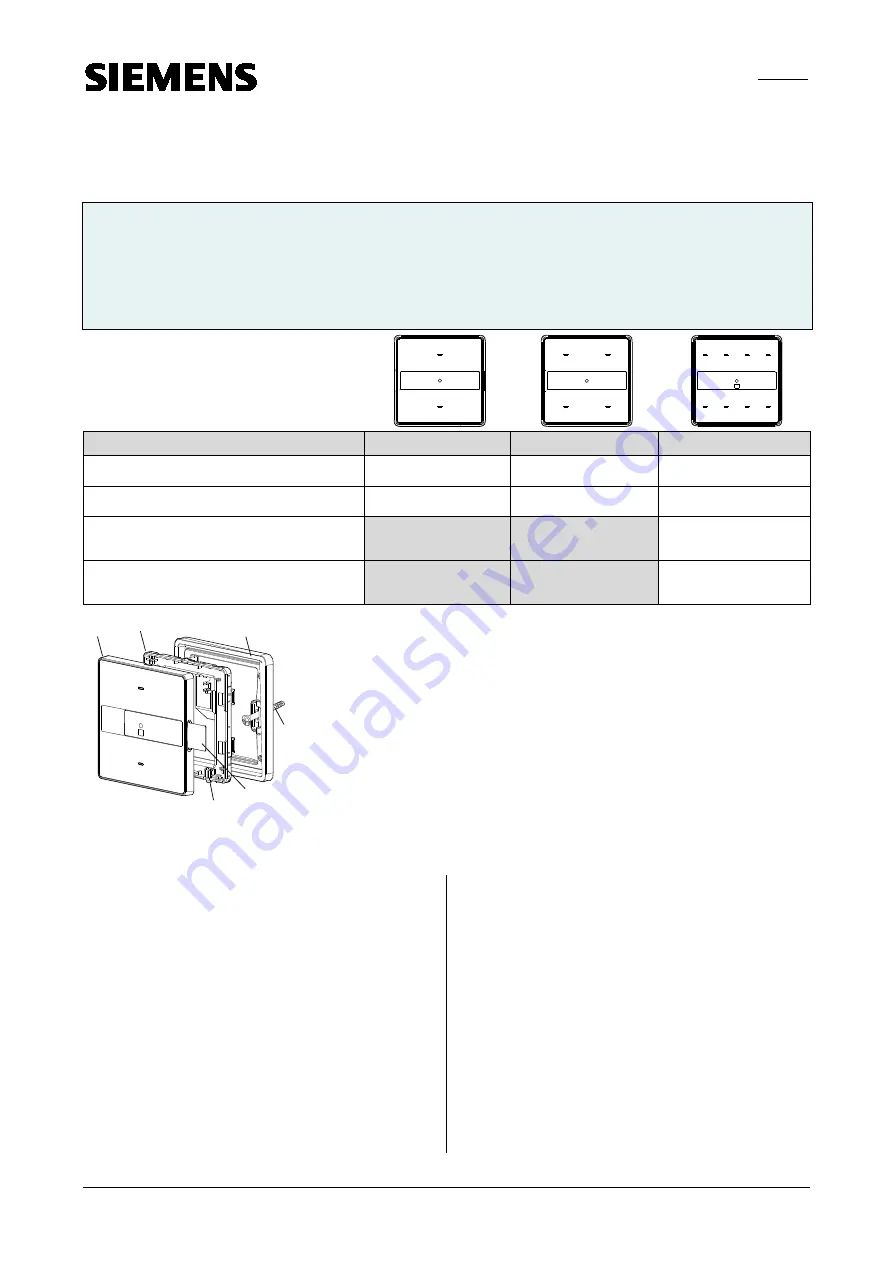

F1

F3

F4

F2

E6

F5

Figure 1: Mounting touch sensor arina

E6

Labelling field

F1

Mounting frame

F2

Mounting screws

F3

Back housing

F4

Front housing

F5

Programming button

Product and Applications Description

The touch sensors for the Gamma arina have one, two or

four vertically arranged pairs of sensitive touch areas. A

paper foil is placed in the middle between these sensitive

touch areas for labeling. The paper foil is replaceable

.

These types of touch sensors are available:

•

Touch sensor single, double and quadruple, with one

orientation LED, without status LED.

•

Touch sensor single, double and quadruple, with one

orientation LED and with one status LED per touch

area.

•

Touch sensor quadruple, with one orientation LED, one

status LED per touch area, scene controller, and room

temperature sensor.

•

Touch sensor quadruple, with one orientation LED, one

status LED per touch area and IR receiver-decoder.

The touch sensors are mounted together with the

mounting frame DELTA® arina onto a 86 mm x 86 mm

conduit box.

The mounting frame is not included and therefore have

to be ordered separately (see current catalog).