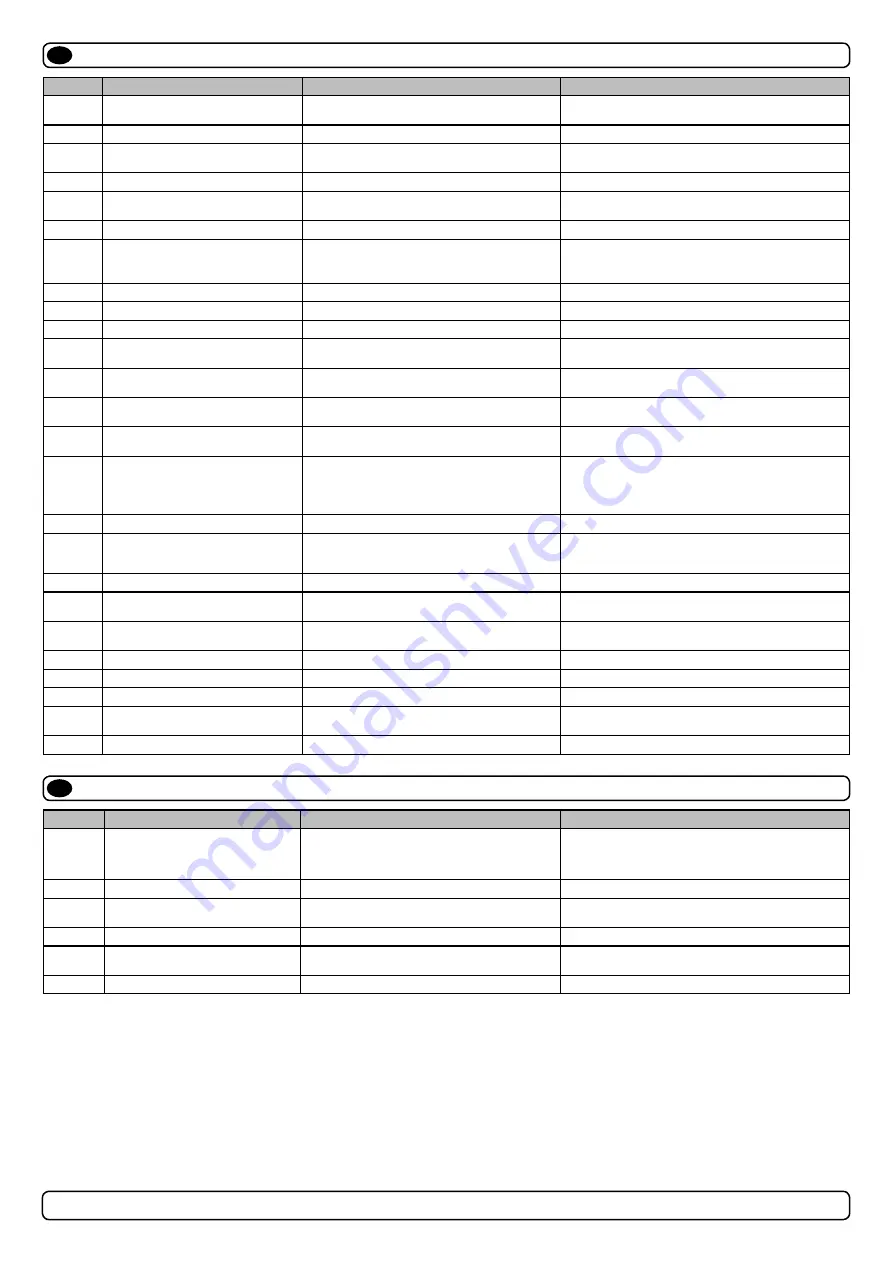

PHC-3 Alarm Descriptions

EN

MC_0117

Fault Code

Description

Cause

Action

10500.0.10

PHC Oil Level - Level Low

Hydraulic oil level is low

-Limit the use of thruster

-Inspect hydraulic oil level

-Check system for leaks and refi ll hydraulic oil

10500.0.13

PHC Oil Level - Open Circuit

Analog oil level sensor open circuit

-Sensor not connected or wire break.

-Verify sensor type in parameter 0201

-Disconnect sensor and measure that sensor resistance value is in

range 0-180ohm.

10501.0.11

PHC Oil Temp - Level High

Oil temperature higher than 75°C (167°F)

-Limit the use of thruster to prevent temperature to rise.

-Check if the cooling pump is running and there is cooling water fl ow.

-Inspect seawater fi lter

-Verify that cooling pump is enabled in parameter 0301

10501.0.13

PHC Oil Temp - Open Circuit

Analog oil temp sensor open circuit

-Sensor not connected or wire break.

- Disconnect sensor and measure that sensor resistance value is in

range 104ohm-147Kohm

-The wrong sensor is defi ned in parameter 0201

10501.0.16

PHC Oil Temp - Short Circuit

Analog oil temp input short circuit

-Input shorted to GND, check wiring/sensor

-Disconnect sensor and measure that sensor resistance value is in

range 104ohm-147Kohm

10502.0.13

PHC Stablizier Pressure - Open Circuit

Stabilizer pressure sensor open circuit

-Sensor not connected or wire break.

-System incorrectly confi gured with stabilizer, parameter 1001

-Replace sensor

10502.0.16

PHC Stablizier Pressure - Short Circuit

Stabilizer pressure sensor short circuit

-Wires shorted or sensor defective, check wiring/sensor

-Replace sensor

10502.0.19

PHC Stablizier Pressure - Under Limit

Stabilizer pressure has dropped below 20bar.

-Check accumulator charge pressure

-Check PTO pressure (if PTO powered)

-Check system for oil leaks

10502.0.20

PHC Stablizier Pressure - Over Limit

Stabilizer pressure is higher than:

set point + 30bar running from PTO

or set point + 15bar running from AC motor

-Check PTO pressure setting

-Check accumulator charge pressure

10502.0.26

PHC Stablizier Pressure - VALUE MAX

Stabilizer pressure reached sensor max value.

-Check that the correct sensor is fi tted

-Check that sensor range parameter 1010 match the sensor

-Check PTO pressure setting

10502.0.200 PHC Stablizier Pressure - Timeout

Stabilizer pressure has not reached 50% of setpoint parame-

ter 1003 after 30sec.

-Check the pump feed shutoff valve.

-Check PTO pressure (if PTO powered)

-Check system for oil leaks

10503.0.13

PHC System Pressure - Open Circuit

System pressure sensor open circuit

-Sensor not connected or wire break.

-Verify system pressure, parameter 0104

10503.0.16

PHC System Pressure - Short Circuit

System pressure sensor short circuit

-Wires shorted or sensor defective, check wiring/sensor

-Replace sensor

10504.0.13

PHC AI 1 - Open Circuit

Analog Input 1 (4-20mA) sensor open circuit

-Sensor not connected or wire break.

10504.0.16

PHC AI 1 - Short Circuit

Analog Input 1 (4-20mA) sensor short circuit

-Wires shorted or sensor defective, check wiring/sensor

-Replace sensor

10505.0.13

PHC AI 2 - Open Circuit

Analog Input 2 (4-20mA) sensor open circuit

-Sensor not connected or wire break.

10505.0.16

PHC AI 2 - Short Circuit

Analog Input 2 (4-20mA) sensor short circuit

-Wires shorted or sensor defective, check wiring/sensor

-Replace sensor

10508.0.13

PHC DOUT AC PUMP UNLOAD - Open Circuit

AC Pump Unload valve open circuit

-Check for open circuit, power consumption < 5.0 Watt

-System incorrectly confi gured with stabilizer, parameter 1001

10508.0.51

PHC DOUT AC PUMP UNLOAD - Current High

AC Pump Unload valve current higher than 4.0A

-Check wires and connections for short circuit

10509.0.13

PHC DOUT ACCUMULATOR DUMP - Open

Circuit

Accumulator Dump valve open circuit

-Check for open circuit, power < 5.0 Watt

-System incorrectly confi gured with stabilizer, parameter 1001

10509.0.51

PHC DOUT ACCUMULATOR DUMP - Current

High

Accumulator Dump valve current higher than 4.0A

-Check wires and connections for short circuit

10510.0.13

PHC DOUT STABILIZER - Open Circuit

Stabilizer valve open circuit

-Check for open circuit, power consumption < 5.0 Watt

-System incorrectly confi gured with stabilizer, parameter 1001

10510.0.51

PHC DOUT STABILIZER - Current High

Stabilizer valve current higher than 4.0A

-Check wires and connections for short circuit

10511.0.13

PHC DOUT COOLING PUMP HYDRAULIC -

Open Circuit

Hydraulic Cooling Pump valve open circuit

-Check for open circuit, power consumption < 5.0 Watt

-Wrong cooling pump confi gured, parameter 0301

10511.0.51

PHC DOUT COOLING PUMP HYDRAULIC -

Current High

Hydraulic Cooling Pump valve current higher than 4.0A

-Check wires and connections for short circuit

10512.0.13

PHC DOUT LS DUMP - Open Circuit

LS-Dump valve open circuit

-Check for open circuit, power consumption < 5.0 Watt

-System wrong confi gured with thrusters, parameter 2001 or 2101

10512.0.51

PHC DOUT LS DUMP - Current High

LS-Dump valve current higher than 4.0A

-Check wires and connections for short circuit

10513.0.51

PHC DOUT PUMP #2 - Current High

Pump #2 valve current higher than 4.0A

-Check wires and connections for short circuit

10514.0.13

PHC DOUT 5 - Open Circuit

Digital Output 5 is confi gured as crossover and output is open

circuit

-Check for open circuit, power consumption < 5.0 Watt

-Output confi gured wrong, parameter 0505

10514.0.51

PHC DOUT 5 - Current High

Digital Output 5 current higher than 4.0A

-Check wires and connections for short circuit

10515.0.13

PHC DOUT 6 - Open Circuit

Digital Output 6 is confi gured as crossover and output is open

circuit

-Check for open circuit, power consumption < 5.0 Watt

-Output confi gured wrong, parameter 0506

10515.0.51

PHC DOUT 6 - Current High

Digital Output 6 current higher than 4.0A

-Check wires and connections for short circuit

10516.0.13

PHC DOUT 3 - Open Circuit

Digital Output 3 is confi gured as crossover and output is open

circuit

-Check for open circuit, power consumption < 5.0 Watt

-Output confi gured wrong, parameter 0503

10516.0.51

PHC DOUT 3 - Current High

Digital Output 3 current higher than 4.0A

-Check wires and connections for short circuit

PHC-3 Alarm Descriptions

EN

MC_0117

Fault Code

Description

Cause

Action

10517.0.13

PHC DOUT 2 - Open Circuit

Digital Output 2 is confi gured as crossover and output is open

circuit

-Check for open circuit, power consumption < 5.0 Watt

-Output confi gured wrong, parameter 0502

10517.0.51

PHC DOUT 2 - Current High

Digital Output 2 current higher than 4.0A

-Check wires and connections for short circuit

10518.0.13

PHC DOUT 1 - Open Circuit

Digital Output 1 is confi gured as crossover and output is open

circuit

-Check for open circuit, power consumption < 5.0 Watt

-Output confi gured wrong, parameter 0501

10518.0.51

PHC DOUT 1 - Current High

Digital Output 1 current higher than 4.0A

-Check wires and connections for short circuit

10519.0.13

PHC DOUT 4 - Open Circuit

Digital Output 4 is confi gured as crossover and output is open

circuit

-Check for open circuit, power consumption < 5.0 Watt

-Output confi gured wrong, parameter 0504

10519.0.51

PHC DOUT 4 - Current High

Digital Output 4 current higher than 4.0A

-Check wires and connections for short circuit

10520.0.51

PHC ECI PUMP POWER FEED - Current High

ECI cooling pump power current higher than 8.0A

-Check pump cable for damage and short circuits

-Make sure the connector on the cooling pump is correctly inserted.

-Replace cooling pump

10521.0.51

PHC Bow Thruster Power - Current High

Bow thruster PVG feed current higher than 3.0A

-Check PVG wires and connections for short circuit

10522.0.51

PHC Stern Thruster Power - Current High

Stern thruster PVG feed current higher than 3.0A

-Check PVG wires and connections for short circuit

10523.0.51

PHC Thruster Power - Current High

Bow or Stern PVG feed current higher than 3.3A

Check all bow and stern PVG signal wires for short circuits

10524.0.51

PHC ECI Cooling Pump - Current High

ECI cooling pump current higher than 13.0A

-Check ECI cooling pump cable for damage and short circuits

-Replace ECI cooling pump

10524.0.53

PHC ECI Cooling Pump - Overvoltage

ECI cooling pump overvoltage, voltage higher than 33.0V

-Check PHC-3 input voltage is below 33.0V

-Replace ECI cooling pump

10524.0.54

PHC ECI Cooling Pump - Undervoltage

ECI cooling pump under voltage, voltage is lower than 18.0V

-Check PHC-3 input voltage is higher than 18.0V

-Replace ECI cooling pump

10524.0.55

PHC ECI Cooling Pump - Overtemp

ECI cooling pump temperature higher than 100°C (212°F)

-Check ECI cooling pump for damages

-Replace ECI cooling pump

10524.0.100 PHC ECI Cooling Pump - No Communication

No communication with ECI cooling pump

-Check if ECI pump is connected

-Check wires to ECI pump for open circuits

-Check power supply cooling pump

-Wrong cooling pump confi gured, parameter 0301

10524.0.205 PHC ECI Cooling Pump - HW FAULT

ECI cooling pump hardware fault

-Replace ECI cooling pump

10526.0.0

PHC ECI Cooling Pump Blocked - -

ECI cooling pump is blocked

-Reset fault and if fault reappears, cooling pump need service or

replacement.

-Check pump inlet for obstacles

10527.1.0

PHC VFD Not Ready Instance 1 -

VFD not ready

-VFD external run enable/power available signal is lost.

10528.1.10

PHC VFD ABB Parameter Instance 1 Level Low ABB ACS550 parameter values 2001 or 2002 cannot be a

negative value.

-Check ABB ACS550 parameter 2001 and 2002.

10529.0.19

PHC ECI Cooling Pump Speed - Under Limit

ECI pump motor speed under limit, below 100rpm

-Check hose for dirt

-Check pump inlet for obstacles

10530.0.201 PHC PTO ENGINE INSTANCE - INIT FAIL

Parameter 1011-PTO ENGINE INSTANCE is not defi ned

-Set parameter 1011-PTO ENGINE INSTANCE

36000.1.24

ABB ACS550 Instance 1 Fault

ABB ACS550 fault

See ABB ACS550 drive for more details

36002.1.24

VACON Instance 1 Fault

VACON VFD Fault

See VACON drive for more details

36100.1.100 VFD Instance 1 No Communication

Lost communication with VFD

-VFD not powered up

-VFD communication cable not connected or incorrectly wired

36103.1.0

VFD IN LOCAL Instance 1 -

VFD in local mode

-Switch VFD to remote mode

PDC-301 Alarm Descriptions

EN

MC_0119

Fault Code

Description

Cause

Action

10600.0.208 SR150000 Fault - INTERLOCK

Retract Interlock

-Check if retract is depoyed.

-No communication with Retract Controller, check Retract Controller

has power.

-Check PDC-301 and Restract Controller setup.

36100.1.24

VFD Instance 1 Fault

VFD faulted

-See VFD for more information

36100.1.100 VFD Instance 1 No Communication

PDC-301 has no MODBUS communication with VFD.

-Check communication cable with VFD

-Check if VFD has power

36101.1.200 VFD PMS Instance 1 Timeout

VFD is not ready within 60 after power reqest.

-Check if VFD has power

36101.1.204 VFD PMS Instance 1 SIGNAL LOST

Lost Power Management signal from VFD, VFD not avilable

anymore.

-Check VFD for more information.

36103.1.0

VFD IN LOCAL Instance 1 -

VFD in Local or Hand Mode

-Change mode in VFD panel.

13

6032

3

2019

-

SEP user manual

Содержание SH SERIES

Страница 18: ...MC_0037 Notes EN 18 6032 3 2019 SEP user manual ...

Страница 19: ...MC_0037 Notes EN 19 6032 3 2019 SEP user manual ...

Страница 20: ...MC_0037 Notes EN 20 6032 3 2019 SEP user manual ...

Страница 21: ...MC_0037 Notes EN 21 6032 3 2019 SEP user manual ...

Страница 22: ...MC_0037 Notes EN 22 6032 3 2019 SEP user manual ...