4

Assembly

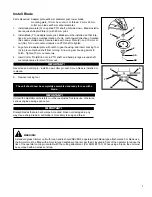

Install Metal Shield

Parts Required:

Metal Shield, Shield Bracket,

3 - 5 x 10 mm screws w/captivated flat and lock-

washer, (metal shield to gear housing).

2 - 5 x 8 mm screws, 2 - 5 mm nuts, 2 - 5 mm lock-

washers, (bracket to shield).

2 - 5 mm nuts, 2 - 5 mm lockwashers

(bracket to gear housing)

1. If installed, remove nylon line head, adapter plate, shield plate, and plastic

shield:

a. Align locking hole in adapter plate with notch in edge of gear housing and

insert locking tool (A).

b. Remove line head (B) by turning it clockwise until head is completely off of

shaft.

c. Remove locking tool.

A

B

C

C

G

F

H

d. Remove three screws holding shield plate (E) and plastic shield (C) to

gear housing.

e. Retain line head (B), adapter plate (D), shield plate (E), and plastic shield

for conversion back to nylon line head operation.

2. Loosely attach bracket (F) to shield (G) and attach shield to bottom of gear

housing (H) with hardware provided.

3. Tighten all shield hardware.

E

D

WARNING!

NEVER operate the unit without the cutting attachment

shield installed and tightly secured!

WARNING!

A cutting attachment shield or other protective device is

no guarantee of protection against ricochet. YOU MUST

ALWAYS GUARD AGAINST FLYING DEBRIS!

Содержание BCK-11

Страница 10: ...10 NOTES...

Страница 11: ...11 NOTES...