ENG-

E-21

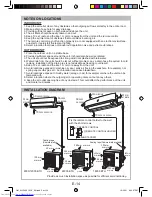

AIR REMOVAL

Lo

Hi

Valve shaft cap tightening torque

Pipe size

Torque

รุนเครื่

องปรับอากาศ

รุนเครื่

องปรับอากาศ

Liquid side

1/4"

24±3N · m (2.4±0.3 kgf · m) AH/AU-PN10, 13, 19 and 24

AH/AU-L10, 13

Gas side

3/8"

9K-Btu/h type

31±3 N · m (3.1±0.3 kgf · m) AH/AU-PN10 and L10

1/2"

12K 18K-Btu/h type

31±3 N · m (3.1±0.3 kgf · m) AH/AU-PN13, 19 and L13

5/8"

24K-Btu/h type

31±3 N · m (3.1±0.3 kgf · m) AH/AU-PN24

Service port cap tightening torque

Torque

11±1 N · m (1.1±0.1 kgf · m)

(1) Remove both valve shaft caps of the 2 and 3-way valves.

(2) Remove the service port cap of the 3-way valve.

(3) Connect the gauge manifold hose to the service port and the vacuum pump.

Be sure that the hose end to be connected to the service port has a valve core pusher.

(4) Open the gauge manifold low-pressure valve(Lo) and operate the vacuum pump for 10-15 minutes.

Make sure the compound gauge reads -0.1 MPa(-76 cmHg).

(5) Close the gauge manifold valve.

(6) Turn off the vacuum pump.

Leave as it for 1-2 minutes and make sure the needle of the compound gauge does not go back.

(7) Open the 2-way valve 90° counterclockwise by turning the hexagon wrench. Close it after 5 second,

and check for gas leakage.*

(8) Disconnect the gauge manifold hose from the service port.

(9) Fully open the 2-way valve with hexagon wrench.

(10) Fully open the 3-way valve with hexagon wrench.

(11) Firmly tighten the service port cap and both valve shaft caps with a torque wrench at the specified

tightening torque.

* Check the pipe connections for gas leak using a leakage detector or soapy water.

Gauge manifold

Compound gauge

Vacuum pump

Service port cap

3-way valve

Valve shaft cap

2-way valve

Hexagon wrench

(Diagonally 4 mm)

OPEN

Service port

CLOSE

OM_AH-PN10 13GY_EN.indd Sec1:21

OM_AH-PN10 13GY_EN.indd Sec1:21

12/22/11 6:30:37 PM

12/22/11 6:30:37 PM