BK-T080III (vertical) User’s Manual

- 27 -

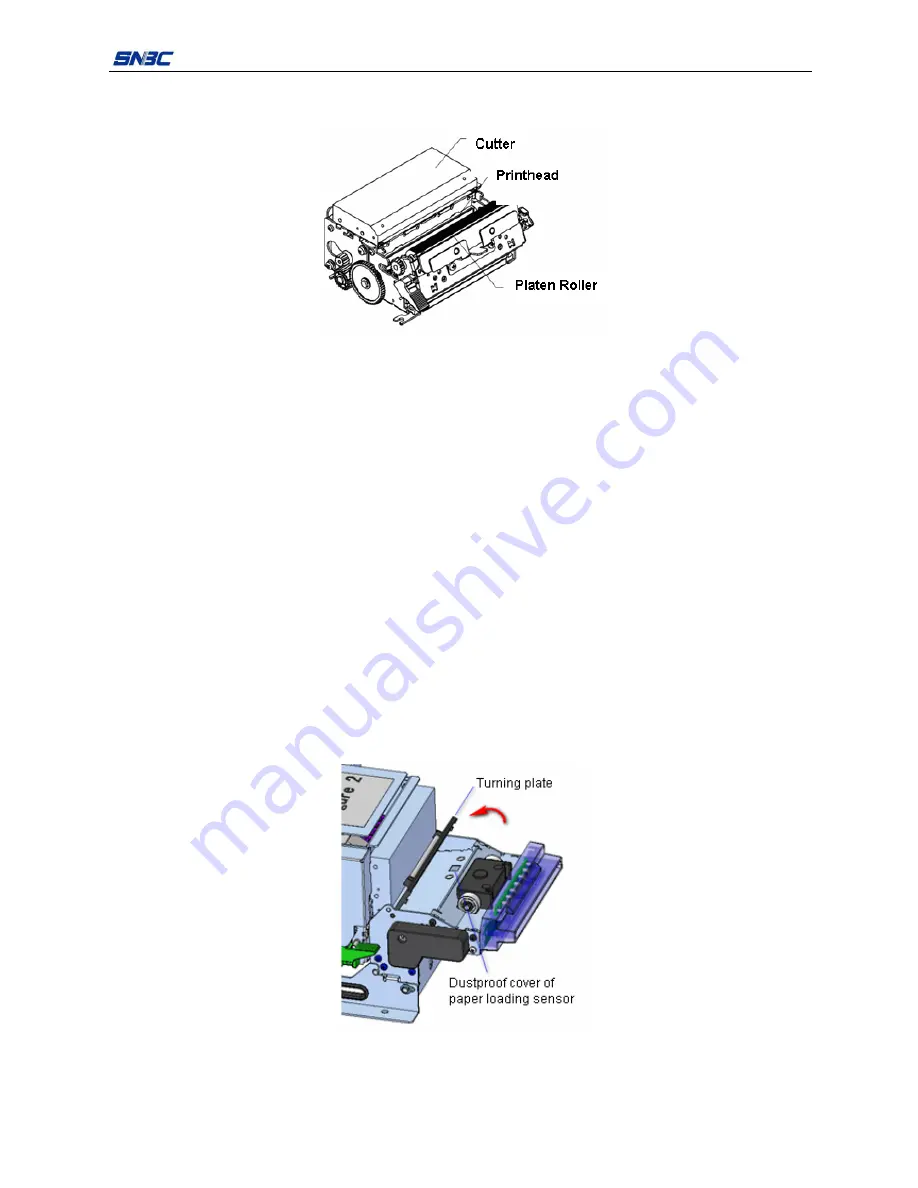

4) The print head is located interior of the cutter, the innermost of mechanism. Wipe off the surface of

print head with alcohol cotton (it should be wrung out before using);

Figure 5.2-2 Cleaning the print head

5) Wipe off the dust or stains on the platen roller with soft cotton cloth dipped with pure ethanol (it

should be wrung out before using);

6) After the print head and the platen roller are dry, execute the assembly in the reverse steps. Then

check whether the connecting cable is connected correctly and start the power.

5.3 Cleaning paper loading sensor

z

When any of the following cases occurs, paper loading sensor should be cleaned.

1) The paper can’t get back to normal printing position during semi-automatic paper loading.

2) The print motor reverses backward for long time during semi-automatic paper loading.

3) After the printing is over, the paper can’t return to normal printing position.

z

To clean paper loading sensor, follow the steps given below:

1) Turn off the power;

2) Turn over the plate in the direction shown in Figure 5.3-1;

3) Then you can see the dustproof cover of paper loading sensor in the PRESENTER path. Wipe off

dust or stains on the sensor surface with soft cotton cloth dipped with pure alcohol (it should be

wrung out before using);

Figure 5.3-1 Cleaning paper loading sensor

4) Wait for 5 to 10 minutes until the pure alcohol evaporates completely, and close PRE top cover

according to the reverse steps, then turn on the power;