Work Sheet: AB-820 500

Pneumatic connections

AB-820500.DOC

24. Jul. 03

Revision: 1.0

Page: 1

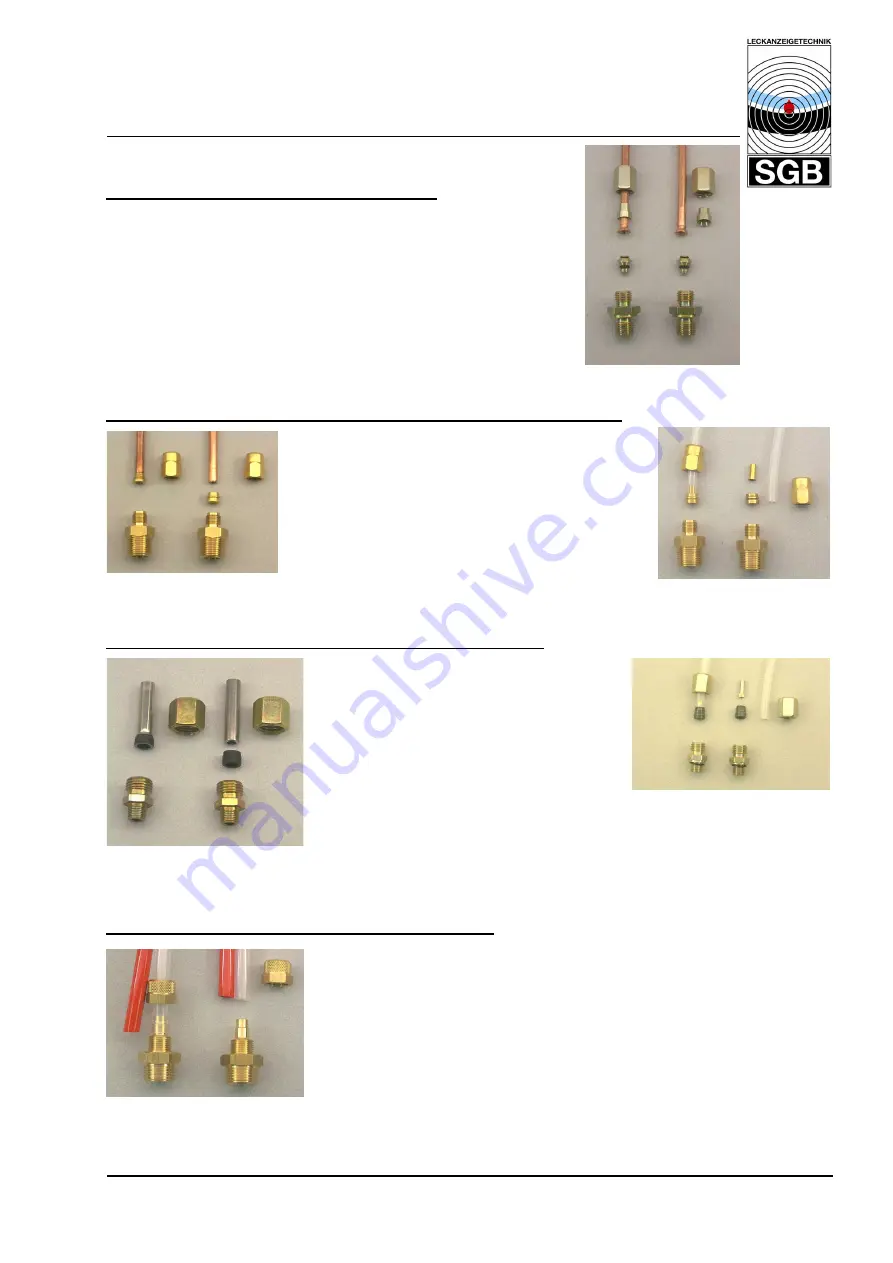

1 Flare type fitting for flare type pipes

1. Lubricate the O-rings

2. Place the intermediate ring loosely in the threaded connection piece

3. Push the union nut and the thrust collar over the pipe

4. Tighten the union nut manually

5. Tighten the union nut until clearly increased force is needed

6. Finished assembly: turn by a further ¼ of a revolution

2 Clamping ring threaded fitting for plastic and metal pipes

1. Insert the support sleeve into the end of the pipe

2. Insert the pipe with support sleeve as far as it will

go

3. Tighten the thread until strong resistance can be

clearly felt

4. Lightly loosen the nut

5. Tighten the nut until resistance can be felt (nut

must exactly match the thread of the basic body)

3 Olive threaded fitting for plastic and metal pipes

1. Insert the reinforcing sleeve into the end of

the pipe

2. Knock in the reinforcing sleeve

3. Push the union nut and the olive over the

end of the pipe

4. Screw the union nut by hand until you feel

a stop

5. Press the pipe against the stop in the inner

cone

6. Tighten the union nut by approx. 1.5 revolutions (pipe must not turn)

7. Loosen the union nut: check whether the pipe visibly projects from under

the cutting ring (it doesn’t matter if the clamping ring can be turned)

8. Retighten the union nut using normal force

4 Quick-action fitting for PA- and PUR-tubes

1. Make a right-angled cut in the PA pipe

2. Loosen the union nut and push it over the end of the pipe

3. Push the pipe onto the nipple up to where the thread begins

4. Tighten the union nut by hand

5. Further tighten the union nut using a wrench until clearly increased force

is needed (approx. 1 to 2 revolutions)

NOT suitable for PE-pipes

38 von 50

Содержание VL-H9

Страница 46: ...46 von 50 By SGB limited to T3...

Страница 47: ...47 von 50...

Страница 48: ...48 von 50...