TOC EVOLUTION:

USER &

MAINTENANCE MANUAL

Page:

72/74

Instructions No.: 10844

This document is the property of SERES and cannot be reproduced without authorization

12 Repair manual

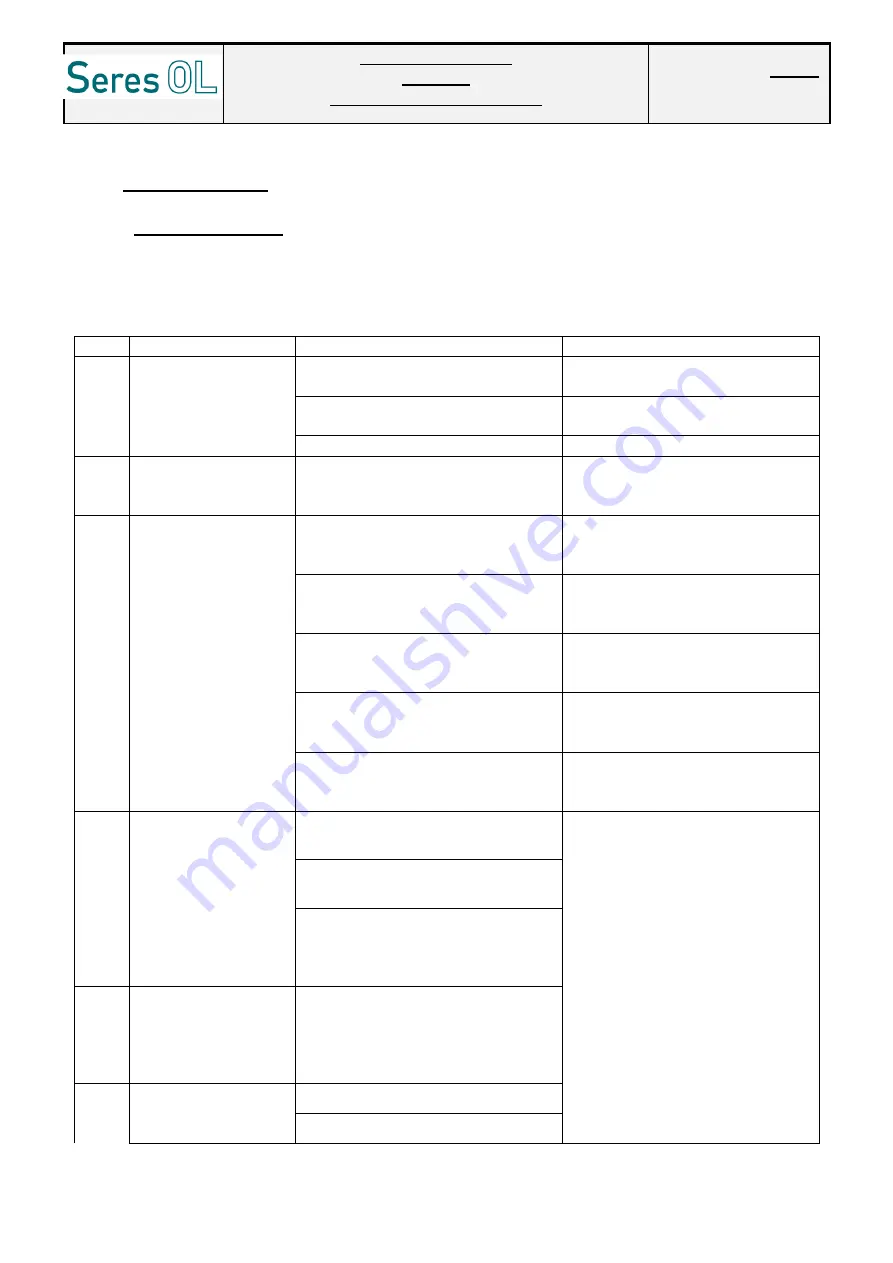

12.1 Failure diagnosis

The following tables list the most common failures and their solutions. To prevent a failure, ensuring the

cleanliness of the different components is essential. It will be necessary, before any failure diagnosis, to clean them

before removing them. We suggest you read the troubleshooting instructions before working on the detector.

No.

Problems

Possible causes

Solutions

1

The device cannot be

switched on.

Power failure or fuses outside the

terminal strip.

Check the power supply voltage or

that the fuses are installed properly.

The power supply is off-line.

Check the power supply output

(24V).

The touch screen is not powered.

Check the power supply connector.

2

The application does

not start.

The device starts up but not the

interface.

Check that the screen is powered

and check that the Ethernet cables

are connected.

3

The "water defect"

alarm is generated

when the sample is

provided correctly

(correct flow rate and

pressure at the

sampling point).

The filling solenoid valve does not

operate correctly.

Check that the filling solenoid valve

is connected properly and that the

LED lights up.

One or more hydraulic pipes are

blocked or pinched.

Check the condition of the pipes.

The supply feed pump is not working.

Check that the pump is connected

correctly.

The water sensor on the fast loop is

faulty.

Check that the sensor is connected

and that the sensor is not blocked.

The water sensor is faulty.

Check that the sensor is connected

and that the pipe is correctly clipped

onto the sensor.

4

The reactor does not

empty itself.

The sewer system is blocked.

Check the condition of the pipes

(internal and external).

The draining solenoid valve does not

operate correctly.

Check that the solenoid valve is

connected correctly.

The draining pipe is pinched and

prevents flowing.

Check that the draining pipe is not

pinched when the door is closed. If it

is pinched, unblock it. Possibly

shorten the pipe.

4

The measurement is

not updated.

The new measurement is identical to

the first or the measuring cycle is

stopped or paused.

Restart the measuring cycle.

5

The screen is not

responding.

The touch screen is damaged.

Switch the device OFF and then ON.

If the problem persists, contact the

after sales department.

The PC PNAL does not respond.