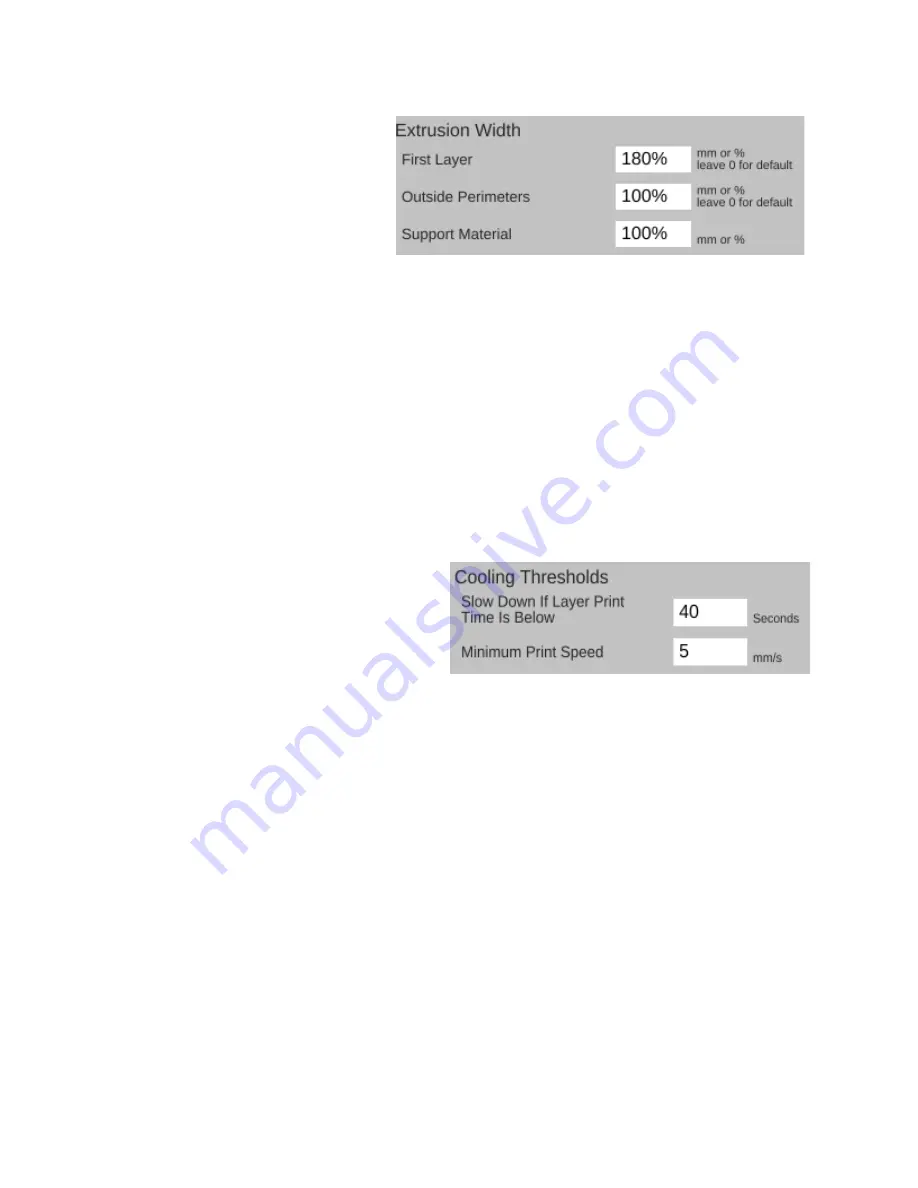

The next page is called

Extrusion

and contains a set of

parameters for dealing with the width

of the material as it's extruded.

The

First Layer

parameter

allows you to specify the extrusion

width of the first layer. A first layer

width that's larger can help with how

the material adheres to the bed. You can specify it as either an actual width, or as a percentage

of the normal extrusion with (typically the same as the nozzle diameter).

Outside Perimeters

will allow you modify the width of the extrusion when you're printing

the outside perimeter of the model. This can come in handy if you need to fine tune the exterior

dimensions if they don't exactly match the model.

Support Material

allows you to specify how wide you want the extrusion to be for the

support structure if you're using it.

The

Cooling

page covers parameters relating to layer cooling.

Cooling Thresholds

allow you to slow

the print speed down during a print if needed.

If the current layer will require more than the

specified time to print, the slicing engine will

automatically slow the print speed down to

meet this goal. This can be important because

if you don't use a fan, a layer will need time to radiate its excess heat before the next layer is

applied. If the material isn't cooled, or given time to cool via radiation, heat can build up in the

underlying layers and cause curling and other undesirable effects.

Minimum Print Speed

can be used to ensure that the printer doesn't slow down TOO

much, which can cause it's own heating problems. For example, if you're printing too slowly, the

presence of the nozzle moving over the surface can cause heating to areas adjacent to the

nozzle tip which can cause blobbing or layer deformation.

Note that there are fan options that be present if you've enabled the operation of the fan.

Because the Eris® has a combination cooling solution that covers both the cold section of the

hot end and the layer cooling feature, the individual fan options are disabled by configuration

option.

49