19

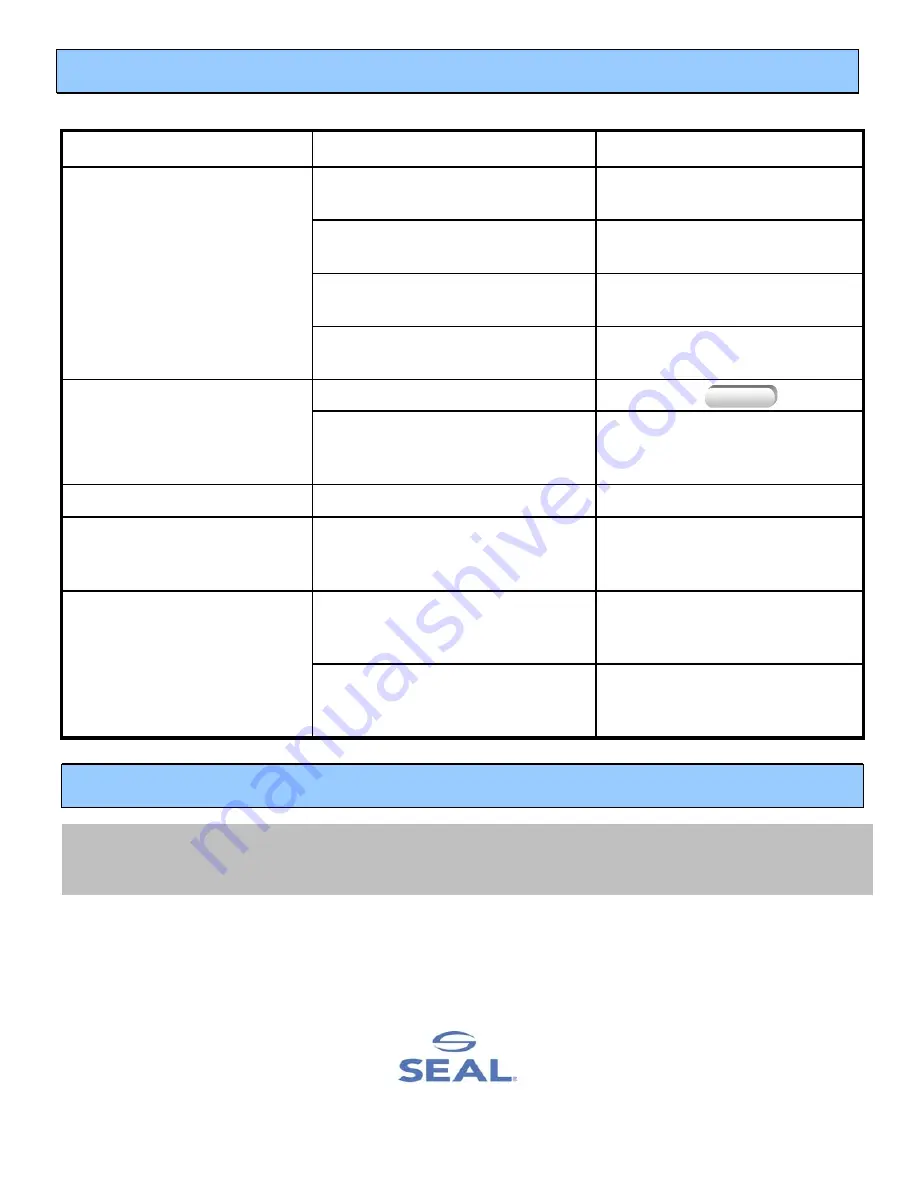

TROUBLE SHOOTING GUIDE

Reverse wrapped film from

around roller, realign top/bottom

film.

1. Top/Bottom films are not aligned.

*Increase the temperature on

the hot roller or decrease the

speed.

1. Increase the temperature on

the hot roller or decrease the

speed.

1. Temperature on the hot roller.

*Adjust film tension.

Reverse wrapped film from

around rollers, reinsert guiding

through pull roll.

2. Leading edge of film has

1. Adjust film tension.

1. Film tension is not proper, too

*Wrinkled lamination result

1. Set proper temperature for the

materials to be used.

2. Memorized temperature may be

lower than atmosphere

temperature.

1. Press the button.

1. Machine is set for Cold Mode.

*Teflon rollers will not heat up.

4. Release STND-BY switch by

press the STND-BY button.

3. Check that the emergency

stop has not been depressed.

3. Machine may be in STAND-BY

mode.

2. Check the main power switch

is on.

2. Emergency switch may be

active.

1. Check that power cord is

plugged in.

1. Check to ensure you have power

to the machine.

*Rollers do not operate after

pressing RUN button

Check Point

Cause

Symptom

C/HOT

WARRANTY

The EP42 comes with a warranty of one year parts and 6 months labor

(except for rubber covered rollers, which carry a 6 month warranty)

Additional extended warranty programs are available.

SEAL Customer Service

(For information and placing orders)

Tel: 1-800-257-7325

Fax: 1-800-966-4554

®

®

SEAL Technical Service

(For technical assistance & service)

Tel: 1-800-486-6502

Fax: 1-800-966-4554

© 2004 SEAL Graphics

SEAL® and Image are registered trademarks of SEAL Graphics

Part #OMEP-42 OM-E Rev. A

(7/04)

jet