Troubleshooting

30

04.00 | FDB | Assembly and Operating Manual | en | 389072

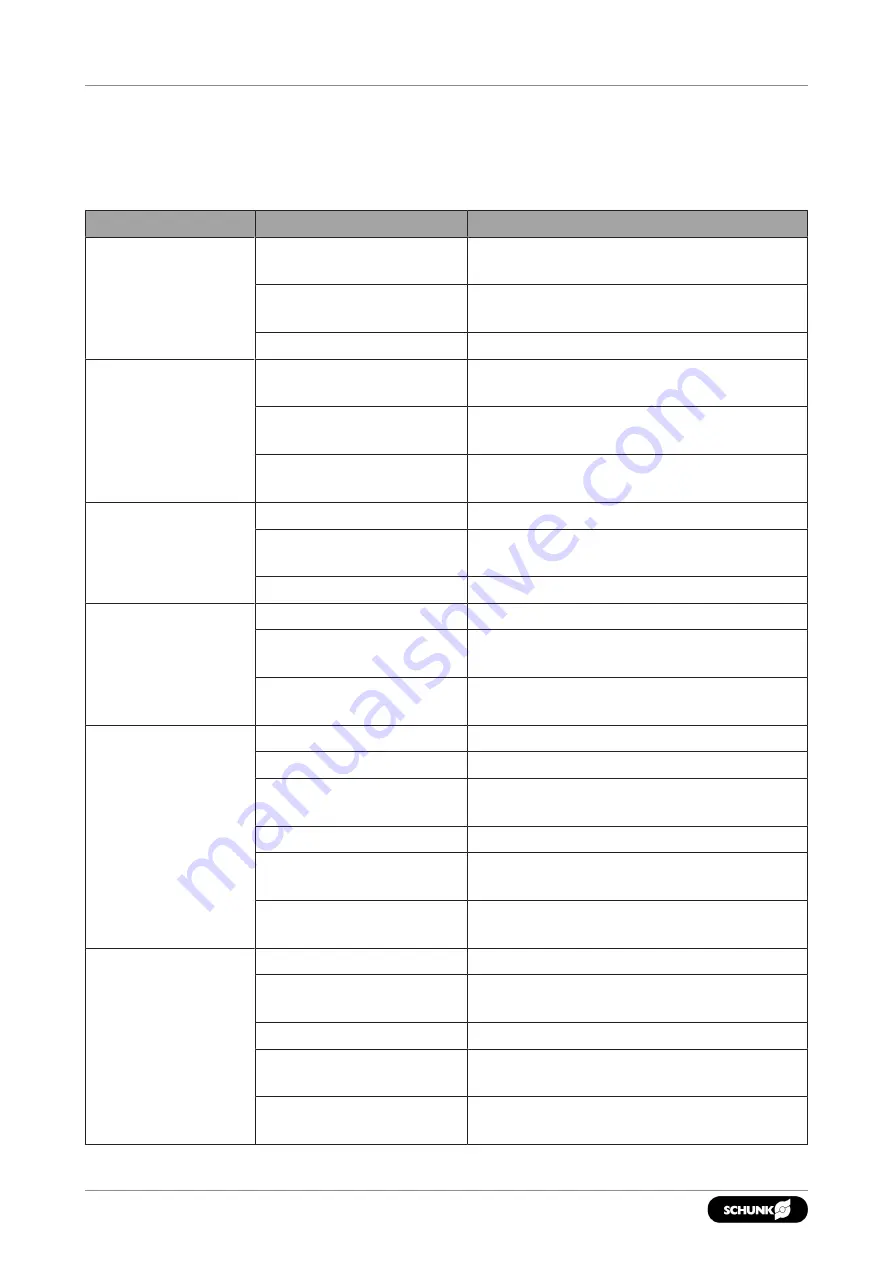

7 Troubleshooting

Deburring process development is an iterative, learning task. The

following table is presented to assist in solving deburring

problems.

Symptom

Cause

Resolution

Burr Wear

Hard work material

Use better grade burr material add

coating (TiAlN)

Too heavy a cut

Decrease width of cut/make multiple

passes

Feed rate is too slow

Increase feed rate

Burr Breakage

Too heavy a cut

Decrease width of cut/make multiple

passes

Deflection at corner

Climb mill/do not begin path at sharp

corner

Impacting part

Decrease feed rate at contact/ enter part

at an angle

Unequal compliance Pivot bearing worn

Replace pivot bearing,

Compliance preload

screw not set properly

Worn ring cylinder

Poor finish on work

piece

Feed rate is too fast

Reduce feed rate

Burr is worn

Inspect burr if worn,

replace.

Motor bearings are worn Inspect spindle shaft, if shaft feels loose

Burr Chattering

during cut

Feed rate is too fast

Reduce feed rate

Lack of rigidity

Increase radial compliance pressure

Too heavy a cut

Decrease width of cut/make multiple

passes

Improper Burr selection

Choose burr designed for work material

Burr is worn

Inspect burr if worn,

replace

Motor bearings are worn Inspect spindle shaft, if shaft feels loose

Secondary Burrs

created on work

piece after cut

Incorrect feed rate

Reduce feed rate

Too heavy a cut

Decrease width of cut/make multiple

passes

Improper Burr selection

Choose burr designed for work material

Burr is worn

Inspect burr if worn,

replace

Motor bearings are worn Inspect spindle shaft, if shaft feels loose