Operating and maintenance instructions

Troubleshooting

Version 1.0

Page 50 of 56

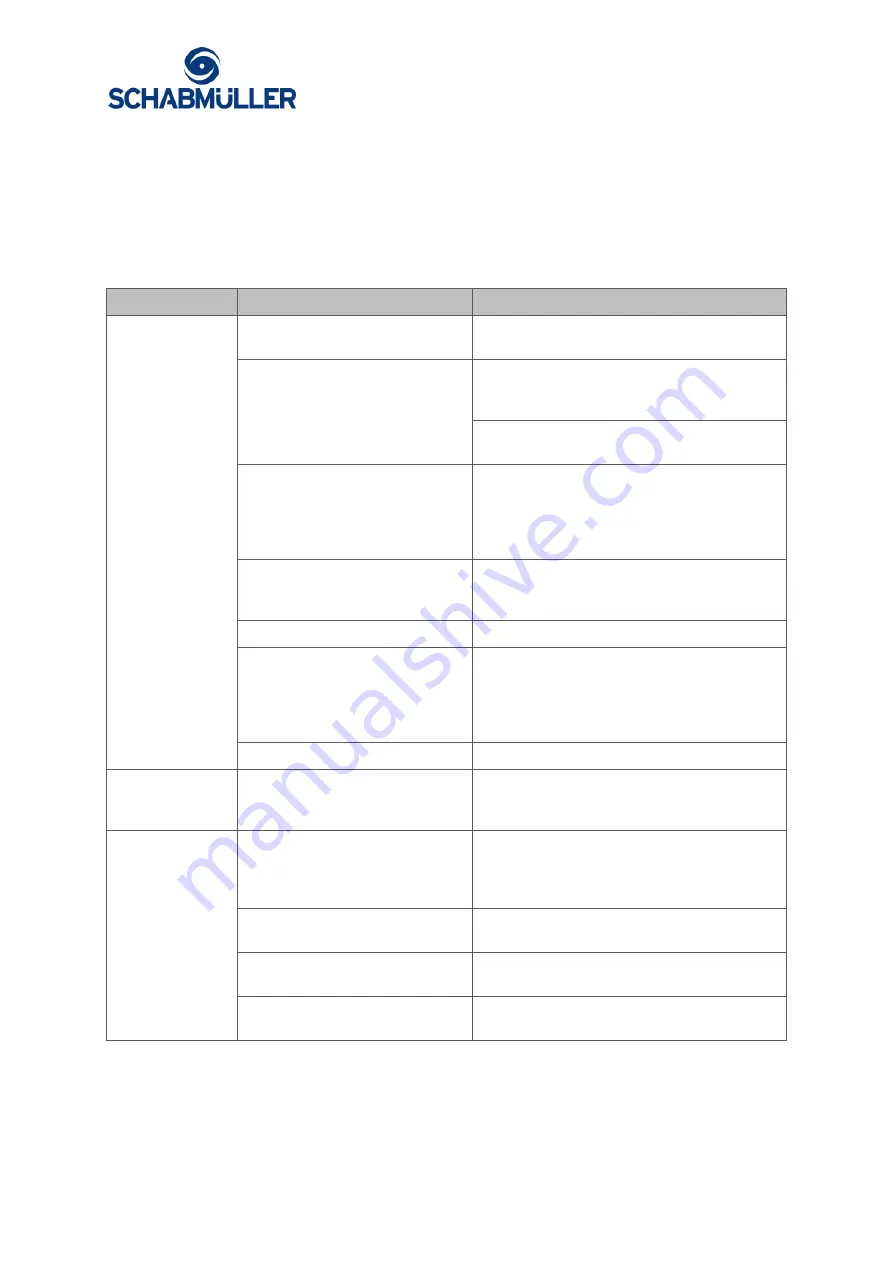

9 Troubleshooting

The following instructions do not cover all the technical details or differences between the

different motors or all the situations that may occur during installation, operation or

maintenance. Inquiries regarding further information should be directed to Schabmüller

GmbH Customer Service.

Fault

Possible cause

Measure

Motor does not

start.

Fuse blown in the vehicle.

Insert new fuses of the correct type and

rating.

Faulty power supply.

Check that the power supply complies with

the specifications on the engine rating plate

and is suitable for the respective load factor.

Check that the connections are correctly

fastened to the terminal board.

Mechanical fault.

Check that the motor rotates freely.

Check the bearings and lubrication.

Check the bearing plates to see if one or both

are broken. Check if there are any foreign

bodies in the motor.

Rotor defective.

Check for broken shaft, loose rotor core or

broken fan blades. Remove any foreign

bodies in the motor that block the rotor.

Motor overloaded.

Reduce the load.

Broken connection on the stator

winding.

Disconnection in the winding.

Recognisable from humming noise when

switched on. Check the wiring for loose

connections.

Check that all contacts are closed.

Motor must be rewound.

Battery or controller defective.

Check and replace if necessary.

Motor only runs

for a short period

of time.

On-board power failure

Check for loose connections to mains, fuses

and controls.

Motor does not

start up.

Undervoltage at motor terminals

due to mains voltage drop.

Use a higher voltage or higher transformer

stage or reduce the load. Check the

connections. Check the cables for

appropriate cross-section.

Incorrect use.

After consultation with Schabmüller GmbH,

use a suitable type or size.

Starting load too high.

Check the design of the engine with regard to

idling.

Broken shaft or loose rotor core.

A new rotor may be required, as a permanent

repair is not possible in this case.