6.

Position the drop box between the angle brackets, keeping a 25mm clearance to combustibles. The located end

of the drop box must protrude no less than 150mm down from the ceiling or any combustible material. Fix the drop

box to the angle brackets.

7.

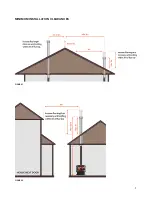

Add the remaining casings to the required height. Australian/New Zealand Standards state that “the flue pipe shall

extend not less than 4.6m above the top of the floor protector”. If the flue pipe is within 3 metres of the ridge, the flue

pipe must protrude at least 600mm above the ridge of the roof. If the distance from the ridge is more than 3 metres,

the flue pipe must protrude at least 1000mm above roof penetration. Additional lengths of casing and flue may be

required to achieve this. The flue pipe must be more than 3 metres from any nearby structure. Other clearances may

be applicable, it is up to the installer to ensure compliance with all regulations.

See Figure 1 and 2 on P7.

8.

Install roof flashing (Additional accessory, not supplied in flue kit)

9.

Secure the Ceiling Collar in place using ceramic spacers and screws provided.

10.

Insert crimped end of the upper decorative flue (without internal stainless steel heat shield) up into the drop box.

Then insert the crimped end of the lower decorative flue (with the internal stainless steel heat shield) up into bottom

of the upper decorative flue. The lower decorative flue features locating tags on the non crimped end which rest on

the heater flue collar. The solid heat shield section of the decorative mesh and stainless steel inner heat shield is to face

the wall.

11.

Feed stainless steel flue through decorative flue and drop box through to the required height. Assemble flue pipes

tight together as you go ensuring seams are straight. Secure each joint with three stainless steel rivets or screws spaced

equally. Clean any finger prints or oils off stainless steel flue with methylated spirits.

12.

Trim the inner flue to the same height as the outer casing. Place cover cone and cowl over stainless steel flue

&

push

cover cone over gal casing. Fix cover cone to gal casing with stainless steel pop rivets or screws.

FOR CONNECTING INTO EXISTING MASONRY CHIMNEY

Any chimney should be fully intact with no holes or missing bricks. We recommend a chimney register be installed above any

installation into a masonry fireplace minimising heat loss up the chimney. The top of the chimney must be sealed using a chimney

plate which should be sealed in place with a mortar mix.

Active flue should be trimmed in line with the top of the chimney if it meets the minimum height requirements under

AS/ NZS 2918. If additional lengths are required to fulfill this requirement these lengths must be cased. The flue should always be

finished with a cowl and cone.

6.

INSTALLATION

....continued

Содержание HEAT & COOK SCX 501

Страница 2: ......

Страница 9: ...MINIMUM INSTALLATION CLEARANCES FIGURE 1 FIGURE 2 7...

Страница 17: ......

Страница 18: ......