Maintenance Guide

All sensors are shipped from the factory pre-calibrated. To maintain accuracy and conformity with standards it is essential that they be

calibrated by a qualified technician once or twice per year.

Calibration Procedure

Use certified precision mixtures to adjust the sensitivity of the sensor due to normal wear and aging and guarantee that the designed alarm

set points are respected. It will also indicate the general condition of a sensor that is due for replacement. So called “automatic calibration”

or “self-test” will not provide this level of security.

Calibration Procedure for Electro-chemical and Catalytic sensors (CO NO2 CH4 NH3 CL2)

1. Use certified bottled calibration gas mixtures only. Ensure that sensors are powered on for a minimum of the break-in period for the

sensor. For electro-chemical type sensors, this is only a few minutes.

2. Press the right arrow to enter settings

3. Press the

↑

and

→

at the same time to enter calibration mode. SAZ (sensor A zero) will display and the current gas reading on the top

line

4. Inject bottled zero gas into first sensor. Use a flow rate of 0.1 LPM to 1 LPM. The gas fitting to sensor should not be sealed tight. If it is

the pressure will increase and distort the reading (high).

5. Adjust gas reading to zero with the

↑

and

↓

buttons

6. Press

↑

and

←

at the same time to save.

7. Press

→

the display will show SAS (sensor A span) and the current gas reading

8. Inject bottled span gas into first sensor and wait until the gas reading stops going up. The span gas should must be within the range of

sensor’s scale.

9. Adjust the reading to match the concentration in the bottle

10. Press

↑

and

←

at the same time to save

11. If second sensor installed press

→

and repeat steps 4 to 10 for sensor B

12. Press left arrow several times to return to settings and home.

Calibration Procedure for Refrigerant (type 13, 20) and VOC (type 01) sensors

1.0 Use certified bottled calibration gas mixed with air only, not nitrogen. Ensure that sensors are powered on for a minimum of the break-in

period for the sensor. For these types sensors, this is two days.

2.0 Inject bottled span gas

3.0 Adjust the blue potentiometer on the module to set the sensor reading displayed to that of the bottle mix. Do not change the factory

calibration constants in calibration mode as above.

4.0 Remove span gas mix and supply air. Sensor will return to zero.

5.0 If sensor does not return to zero, it needs replacement

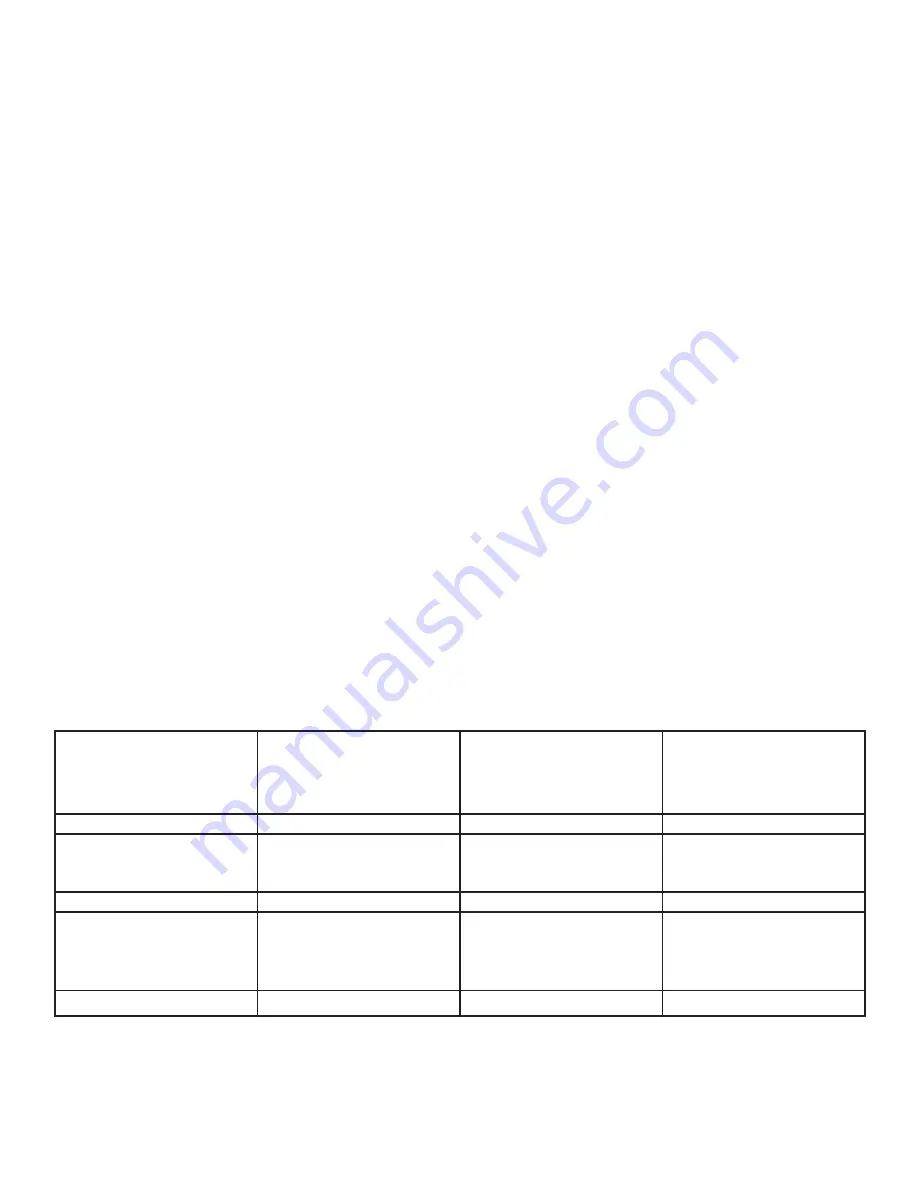

BACnet Network Configuration

Setting 46

Bacnet Mode select

0 = communication disabled

1 = communication enabled

2 = communication enabled and display all

sensors on CAN network

0, 1, 2

Default 0

Setting 47

BMA MAC address

0-127

0

Setting 48

Baud rate

0 = 9600

1 = 19200

2 = 38400

3 = 76800

3

Setting 53

Max Master

1-127

127

Setting 54

Diagnostic tool to test MSTP

communication. Format XXXYYZZ where

YY= ID of device that passed token to

current sensor and YY = ID if device that

received token.

Setting 70

Device ID

4,194,304

50,000+BMA