26 S&C Instruction Sheet 765-510

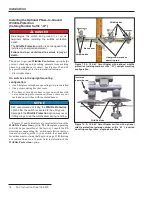

Figure 28. Key-interlock group detail.

Interlock

(with

⅜

-inch bolt

projection and

¾-inch bolt travel)

Vertical operating

pipe

Locking

disc

Interlock bracket

Gaining channel

(used on round

poles only)

Foot-

bearing

assembly

Operating-

handle

assembly

⅜

-inch

(9.5 mm)

Locking the Operating Handle

NOTICE

If ordered with provisions for power operation with

the 6801M Automatic Switch Operator (catalog

number suffix “-M”), omit Step 20 and proceed with

the locking instructions described in the 6801M

Operator installation instructions (S&C Instruction

Sheet 1045M-510). Once the 6801M operator locking

instructions have been followed, proceed with Step 21

of this instruction sheet.

STEP 20.

With padlock:

The operating-handle assembly

includes swing-away hasps for padlocking the

interrupter switch in either the

Open

or

Closed

position.

With key interlock:

The interlock group (see

Figure 28) includes a Superior key interlock,

Type B6003-1 Mk II single or multiple key (or

equivalent), with

⅜

-inch bolt projection and

¾-inch bolt travel, locking disc, and interlock

bracket. If “provision only” for a key interlock

is specified, the interlock will not be included.

See Figure 28. Assemble with the operating-

handle assembly as follows:

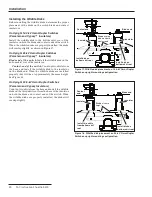

If necessary to compensate for the taper of

the wood pole and to keep the vertical operating

pipe aligned and plumb, shift the guide bearings

toward or away from the pole. Alignment slots

are provided for this purpose. See Figures 9 and

10 on page 15.

(a) Slide the interlock bracket, locking disc,

operating-handle assembly, and foot-

bearing assembly onto the lowest vertical

operating pipe section with the locking disc

and the operating-handle assembly between

the interlock bracket and the foot-bearing

assembly, as illustrated in Figure 28. Bolt the

foot-bearing assembly to the pole at the

position shown on the erection drawing. At

the same time, use one of the mounting bolts

to attach one end of the grounding strap (the

end with the grounding connector attached)

to the foot-bearing assembly

●

.

●

The grounding recommendations described in this document may

differ from the standard operating and safety procedures of certain

electric utility companies. Where a discrepancy exists, the operating

procedures of the electric utility apply.

Installation