14 S&C Instruction Sheet 765-510

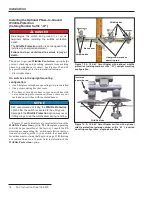

Figure 7. Attaching the uppermost vertical operating pipe to

the switch for an upright mounting configuration.

Vertical operating

pipe

Universal coupling

Installing the Vertical Operating Pipe

S&C recommends assembling each coupling

as work

progresses

from the top down, starting with the univer-

sal coupling connecting the switch to the upper section

of vertical operating pipe. Continue with the universal

coupling between the upper section of vertical operating

pipe and the fi rst lower section, the splice couplings con-

necting the lower sections of pipe to each other, and end

with the rotating operating handle or 6801M Automatic

Switch Operator.

Variations in the surface and height of the wood pole

and/or operating pipe are easier to adjust for when the

switch is installed in this manner.

NOTICE

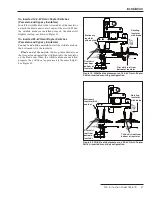

Installing Piercing Set Screw

This equipment uses piercing set screws to couple

the operating mechanism to the operating pipe and to

provide stability to the couplings joining one or more

lengths of pipe.

Before assembling a coupling, back the piercing

set screw out of the coupling so the tip does not

protrude into the body of the coupling. This ensures

the coupling’s clamp screws can be fully tightened.

After the operator assembly is in place, tighten the

piercing set screw, piercing the pipe, and continue

until resistance is felt. It is not necessary to fully

tighten the piercing set screw.

STEP 5.

Locate the universal coupling shipped in the

carton of switch ED parts. Attach the universal

coupling to the rotating shaft of the toggle

mechanism using the

½

-inch stainless steel pin,

fl atwasher, and cotter pin provided. See Figure

7 or 8, as applicable. Install the uppermost

section of the predrilled vertical operating pipe

in the universal coupling as shown. Then, secure

the vertical operating pipe to the universal

coupling using the

½

× 13 × 2

½

-inch bolt,

fl atwasher, and nut provided.

If only one

vertical pipe section is used, omit Steps 6

through 9 and proceed to Step 10.

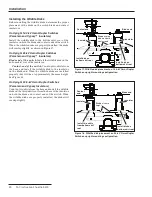

Figure 8. Attaching the uppermost vertical operating pipe to

the switch for triangular mounting configuration.

Universal

coupling

Vertical

operating pipe

Installation