34

EB 8384-5 EN

Attachment to the control valve – Mounting parts and accessories

2.

Place coupling wheel (4) with flat side

facing the actuator on the follower clamp

(3). Refer to Fig. 11 to align slot so that it

matches the direction of rotation when the

valve is in its closed position.

3.

Fasten the coupling wheel (4) and follow-

er clamp (3) tightly onto the actuator shaft

using screw (4.1) and disk spring (4.2).

4.

Fasten the bottom pair of brackets (10.1)

with the bends pointing either facing to

the inside or to the outside (depending on

the actuator size) onto the actuator hous-

ing. Position the top pair of brackets (10)

and fasten.

5.

Mount connecting plate (6) or pressure

gauge bracket (7) with pressure gauges

on the positioner, making sure the two

seals are seated properly.

Double-acting

springless rotary actuators require the use

of a reversing amplifier on the connection

side of the positioner housing (see section

4.6).

6.

Unscrew the standard follower pin (2)

from the positioner's

M

lever (1). Use the

metal follower pin (Ø 5 mm) included in

the mounting kit and screw tight into the

hole for pin position

90°

.

7. Place positioner on the top bracket (10)

and fasten tight. Taking the actuator's di-

rection of rotation into account, adjust le-

ver (1) so that it engages in the slot of the

coupling wheel (4) with its follower pin

(Fig. 11). It must be guaranteed that the

lever (1) is parallel to the long side of the

positioner when the actuator is at half its

angle of rotation.

8. Stick the scale plate (4.3) on the coupling

wheel so that the arrow tip indicates the

closed position and it can be easily read

when the valve is installed.

4.5.1

Heavy-duty version

Fig. 12

−

Required mounting parts and accesso

-

ries: Table 5 on page 51

Both mounting kits contain all the necessary

mounting parts. The parts for the actuator

size used must be selected from the mount-

ing kit.

Prepare actuator, and mount required adapt-

er supplied by the actuator manufacturer, if

necessary.

1.

Mount the housing (10) onto the rotary

actuator. In case of VDI/VDE attachment,

1.2

1.1

1

2

4.1

4.2

5

3

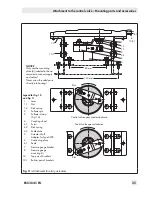

Fig. 10:

Mounting the coupling wheel on

Type 3278

10

10.1

6

(7, 8)

1.1

2

4.3

5

6.1

4

1.2

1

130 mm

80 mm

NOTICE

Only use the connecting

plate (6) included in the ac

-

cessories to connect supply

and output!

Never screw threaded parts

directly into housing!

Legend for Fig. 10

and Fig. 11

1

Lever

1.1

Nut

1.2

Disk spring

2

Follower pin

3

Follower clamp

(Fig. 10)

4

Coupling wheel

4.1

Screw

4.2

Disk spring

4.3

Scale plate

5

Actuator shaft

Adapter for Type 3278

6

Connecting plate

6.1

Seals

7

Pressure gauge bracket

8

Pressure gauge

mounting kit

10

Top pair of brackets

10.1

Bottom pair of brackets

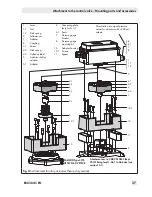

Control valve opens counterclockwise

Control valve opens clockwise

Slot

Slot

Fig. 11:

Attachment to rotary actuators

Содержание FOUNDATION 3730-5

Страница 106: ...106 EB 8384 5 EN...

Страница 107: ...EB 8384 5 EN 107...

Страница 108: ...108 EB 8384 5 EN...

Страница 109: ...EB 8384 5 EN 109...

Страница 110: ...110 EB 8384 5 EN...

Страница 111: ...EB 8384 5 EN 111...

Страница 112: ...112 EB 8384 5 EN...

Страница 113: ...EB 8384 5 EN 113...

Страница 114: ...114 EB 8384 5 EN...

Страница 115: ...EB 8384 5 EN 115...

Страница 116: ...116 EB 8384 5 EN...

Страница 117: ...EB 8384 5 EN 117...

Страница 118: ...118 EB 8384 5 EN...

Страница 119: ...EB 8384 5 EN 119...

Страница 120: ...120 EB 8384 5 EN...

Страница 121: ...EB 8384 5 EN 121...

Страница 122: ...122 EB 8384 5 EN...

Страница 123: ...EB 8384 5 EN 123...

Страница 124: ...124 EB 8384 5 EN...

Страница 125: ...EB 8384 5 EN 125...

Страница 126: ...126 EB 8384 5 EN...

Страница 127: ...EB 8384 5 EN 127...

Страница 128: ...128 EB 8384 5 EN...

Страница 129: ...EB 8384 5 EN 129...

Страница 130: ...130 EB 8384 5 EN...

Страница 131: ...EB 8384 5 EN 131...