Version B June, 2020

11

MagnaRam-SK

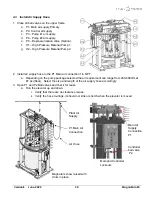

1.11 General Electrostatic Systems

The introduction of high voltage electricity into a highly volatile and explosive atmosphere requires that the

following additional design practices be observed for electrostatic spray operations:

1. Transformers, power packs, control apparatus, and all other electrical portions of the equipment,

(except for high voltage grids and cascades and electrostatic atomizing heads and their

connections) should be located outside the spraying area, unless otherwise specified.

2. The electrostatic apparatus should be equipped with automatic controls to disconnect the power

supply to the high voltage transformer and the operator should be signaled in the event of the

following:

a. Failure or stoppage of the ventilating equipment from any cause;

b. Stoppage of the conveyor carrying items through the spray area;

c. Occurrence of a ground or excessive current leakage at any point in the system;

d. Reduction of the clearance between the articles being coated and the electrodes or

atomizing heads to less than the minimum sparking distance. (A sign indicating this safe

distance should be conspicuously posted near the operation).

3. High voltage leads to electrodes and electrostatic atomizing heads should be effectively and

permanently supported on suitable insulators and should be effectively guarded against accidental

contact or grounding.

4. An automatic means should be provided for grounding and discharging any accumulated residual

charge on the electrode assembly or the secondary circuit of the high voltage transformer when the

transformer primary is disconnected from the source of supply.

5. The articles being coated should be supported on conveyors which are arranged as to maintain a

proper electrical pathway to neutral earth and assure that there is a minimum safe sparking

distance between the substrate and electrostatic equipment at all times.

6. Adequate booth, fencing, guards, or railings should be placed around the equipment for the

protection of personnel. These should consist of conducting material which is adequately grounded

and placed at least 5 feet from the spraying equipment.

7. Warning signs should be conspicuously posted in the area pointing out the hazards of high voltage

equipment in a coating environment.

8. The areas used for electrostatic spraying should be protected by automatic fire extinguishing

equipment.

9. If electrically conductive paint is used, the paint tank isolation stand and paint lines should be

barricaded so that personnel or other equipment will not come in contact with or near proximity to

the high voltage in that portion of the system.

Содержание Magna-Ram

Страница 1: ...USER MANUAL Magna Ram 300 Gallon Elevator and Controls...

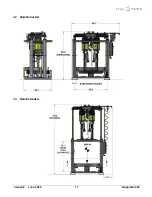

Страница 17: ...Version B June 2020 17 MagnaRam SK 3 2 Ram Retracted 3 3 Ram Extended...

Страница 18: ...Version B June 2020 18 MagnaRam SK 3 4 Load Height...

Страница 43: ...Version B June 2020 43 MagnaRam SK 7 6 4 Control Box Door Layout...

Страница 44: ...Version B June 2020 44 MagnaRam SK 7 6 5 Control Box Subplate Layout...

Страница 45: ...Version B June 2020 45 MagnaRam SK 7 6 6 Control Box Back Layout...

Страница 80: ...Version B June 2020 80 MagnaRam SK 10 Control Drawings 45 0538 00 Drawings...