21

Instruction Manual

7-2 모터교환 시 커버 탈착방법

7-2 Removal ad installation of cover

replacing the motor

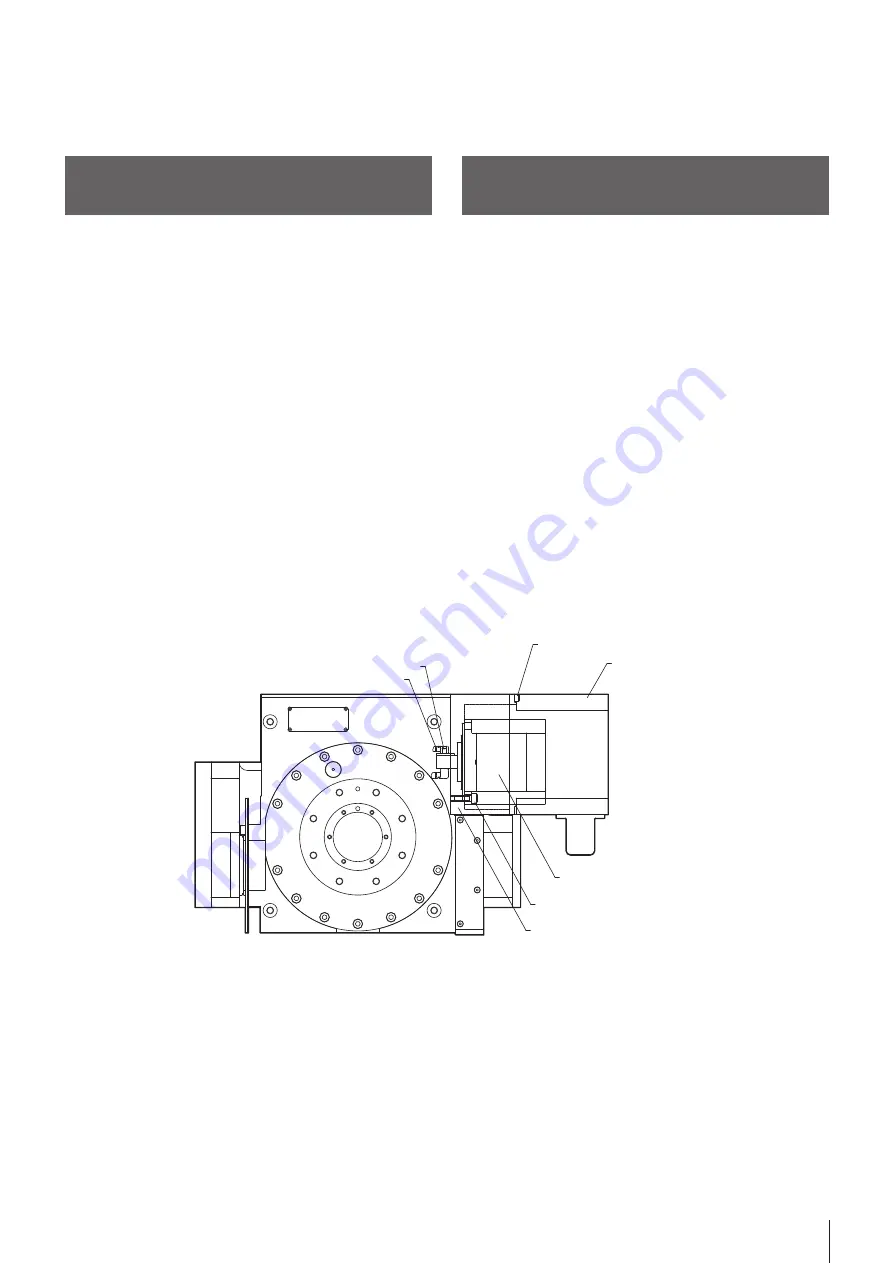

[ 그림 / Fig.8 ]

1) ① MOTOR COVER를 고정하는 ② WRENCH BOLT 4개를 제거 합니다.

(주의 : ① MOTOR COVER를 탈거하면 닿는 면에 O-RING이 있습니다.

O-RING이 분실 및 파손 되지 않도록 주의 합니다.)

2) 이 때, 연결된 내부의 케이블을 분리한 후, 손상 되지 않도록 주의 하면서

① MOTOR COVER를 탈거 합니다.

3) ④ BODY에 고정된 ⑤ SERVO MOTOR를 고정하고 있는 ③ WRENCH

BOLT 4개를 제거 합니다.

4) 모터를 탈거 한 후, ⑦ GEAR와 함께 체결 되어 있는 ⑥ WRENCH BOLT

6개를 제거 합니다. (주의 : ⑤ SERVO MOTOR 를 제거 하면 이물질이 유

입 되지 않도록 O-RING이 있습니다. O-RING이 분실 및 파손 되지 않도

록 주의 합니다. )

5) ⑦ GEAR와 함께 분해되는 KEY, RING 등을 분해 한 후에 모터를 교체 합

니다.

6) 모터를 교체 하면 ⑦ GEAR와 함께 KEY와 RING을 조립하고 ⑦ GEAR를

지지 하는 ⑥ WRENCH BOLT 6개를 체결 합니다.

7) 이전에 사용 했던 O-RING를 BODY에 조립 후, ⑤ SERVO MOTOR를 기

준경에 맞추어서 끼워 넣습니다.

8) ③ WRENCH BOLT 4개를 ⑤ SERVO MOTOR 체결부에 고정 합니다.

9) ① MOTOR COVER 내부에 연결되어 있는 케이블을 정리 합니다.

10) ④ BODY 면에 O-RING을 끼워 넣은 후, ① MOTOR COVER와 ②

WRENCH BOLT 4개를 이용하여 조립 합니다.

1) To remove the ②wrench bolt 4 one to fix the ①motor cover (note:

careful .O-ring is not lost or damaged ①motor cover to the plane hit

and to decompose there is o-ring)

2) In this case, after you remove the internal connection cable, being

careful not to damage, and disassemble the ①motor cover.

3) Disassemble the ⑤servo motor fixed ③wrench bolt 4ea that is fixed

to the ④body.

4) After disassembling the motor, remove the ⑥wrench bolt 6ea that are

fastened together with the ⑦gear. (Note: when you delete a ⑤servo

motor, please be careful .O-ring is not lost or damaged there is o-ring

so that foreign matter does not enter.)

5) After disassembling. Key and ring is decomposed with ⑦gear, replace

the motor.

6) Assemble the key and ring with ⑦gear to replace the motor and then

entered into a ⑥wrench bolt 6 ea to support the ⑦gear.

7) After assembling the o-ring, which has been used in body before, and

insert to fit the ⑤servo motor to the reference diameter.

8) ③Wrench bolt 4ea that you fixed to ⑤servo motor fastened

9) Clean the cables that are connected to the internal ①motor cover

10) Insert o-ring on ④body surface, assemble ①motor cover by using

②wrenchbolt 4ea.

모터에 절삭유가 침투하지 않도록 모터커버와 몸체 사이의 연결부분에

O-RING 이 설치되어 있습니다.

모터커버 및 케이블 파손 때문에 절삭유가 모터커버로 들어가면

전기장치(모터, 솔레노이드 밸브 등)가 손상되므로 주의를 요하며 만약

손상되면 새 부품으로 즉시 교체해야 합니다.

An O-ring is provided between the motor cover and main body to

prevent the cutting fluid from entering the motor.

If the cutting fluid enters the motor cover due to damaged motor cover

or cable, the electric devices (motor, solenoid valve, etc.) can be

damaged. Damaged parts/components must be replaced with new

parts/components immediately.

7.2.1. 방수대책

7.2.1. Waterproofing Measures

① MOTOR COVER

④ COUPLING

⑤ SETSCREW

② WRENCH BOLT

③ WRENCH BOLT

⑦ SERVO MOTOR

⑥ MOTOR PLATE

Содержание SR-200

Страница 2: ...2 NC Rotary Table...