Operator’s manual

Double-sided disc mowers

with central suspension

- 16 -

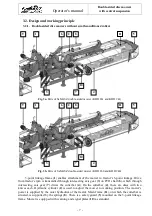

Tab. 4 . Location of centre of gravity

Dimension

[ft, in]

Model

KDD 941

(H)

KDD 941 S

(H)

KDD 941

ST (H)

KDD 940

W (H)

KDD 940

WT (H)

KDD 940 S

(H)

KDD 940

ST (H)

A

16' 1"

16' 1"

16' 1"

16' 1"

16' 1"

16' 1"

16' 1"

B

16' 1"

16' 1"

16' 1"

16' 1"

16' 1"

16' 1"

16' 1"

C

3' 8"

3' 12 "

5' 4"

3' 8"

5' 5"

3' 5"

4' 5"

D

3' 0"

3' 3"

3' 11"

3' 1"

4' 0"

3' 1"

4' 3"

E

2' 1"

2' 1"

2' 8"

3' 1"

2' 9"

2' 1"

3' 0"

F

1' 7"

1' 7"

1' 10"

1' 6"

1' 9"

1' 7"

1' 8"

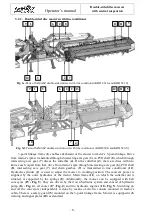

Dimension

[ft, in]

Model

KDD 861

(H)

KDD 861 S

(H)

KDD 861

ST (H)

KDD 861

W (H)

KDD 860

WT (H)

KDD 860 S

(H)

KDD 860

ST (H)

A

14' 8"

14' 8"

14' 8"

14' 8"

14' 8"

14' 8"

14' 8"

B

14' 8"

14' 8"

14' 8"

14' 8"

14' 8"

14' 8"

14' 8"

C

3' 8"

3' 12"

5' 4"

3' 8"

5' 5"

3' 5"

4' 5"

D

3' 0"

3' 3"

3' 11"

3' 1"

4' 0"

3' 1"

4' 3"

E

2' 1"

2' 11"

2' 8"

3' 1"

2' 9"

2' 1"

3' 0"

F

1' 7"

1' 7"

1' 10"

1' 6"

1' 9"

1' 7"

1' 8"

4.4.

Working parts

Before operating the mower, check knife’s and knife holder’s condition.

Worn or damaged knives or knife holders should be immediately replaced with new ones.

4.5.

PTO shaft

Before operating, read bar manufacturer's manual placed on the bar. Follow all safety

precautions in that manual.

Use only PTO shafts recommended by mower’s manufacturer with guards in good condition.

In order to operate safely, use only undamaged PTO shafts and shields. Damaged PTO shafts

and shields must be repaired or replaced with new ones before use.

4.6.

Hydraulic assembly

Hydraulic assembly is under high pressure. Hydraulic oil under pressure may penetrate skin

and cause serious injury or death. Skin and eyes should be protected when working around this

assembly.

In case of injury caused by a liquid under pressure, call a doctor immediately.

Hydraulic hoses can be connected to the tractor's hydraulics provided that both the tractor’s and

the mower's hydraulic assemblies are not under pressure. To remove the pressure from the

hoses, start the tractor's hydraulic valves several times with the tractor off.

When looking for oil leaks, do so safely. Use a cardboard card. Do not touch any potential

leaks until the entire hydraulic assembly has been relieved of pressure.

Use only hydraulic oil featuring oil purity class 9 - 10 in accordance with NAS 1638.