Operator’s manual

Double-sided disc mowers

with central suspension

- 11 -

Tab. 3. Recommended PTO shafts for KDD mowers

Model

Power

Length

Torque

Symbol

Manufact

urer

KM

mm

Nm

KDD 860, KDD 940,

KDD 861 (H), KDD 941 (H)

100

1210 - 1710

956

CS8N121CER07R07LA

Bondioli-

Pavesi

KDD 860 S/W (T),

KDD 940 S/W (T),

KDD 961 S (T),

KDD 941 S (T)

100

1210 - 1710

956

CH8N121CER07R09LA

Bondioli-

Pavesi

NOTE:

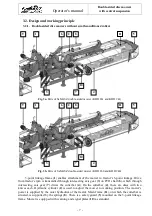

Lubricate the PTO shaft with high quality multi-purpose grease every

50 shaft operating hours (Fig. 7). If access holes are accessible, lubricate

fittings through access holes.

Fig. 7. PTO shaft lubrication points. Mounting directions

PTO shafts of other brands with equivalent parameters could be used after first obtaining SaMASZ

permission.

NOTE:

Optional extra equipment should be ordered separately.

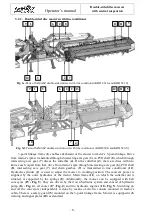

The mower is equipped with optional equipment such as holders and brackets used to mount

warning lights and plates. Combined lights and reflectors are mounted on warning plates.

PTO shaft’s end without clutch – To

be mounted on the tractor’s side.

PTO shaft’s end with overrunning

clutch – To be mounted

on mower’s side