ENGLISH

3.

Connect the delivery pipe or hose directly to the pump mouth. If the pump is used in fixed

installations it is advisable to connect it to the pipe with a coupling so as to facilitate

disassembly and reinstallation. If a hose is used, fit a threaded hosetail on the pump mouth.

Wrap the thread with suitable material to ensure an effective seal (teflon tape or similar).

4.

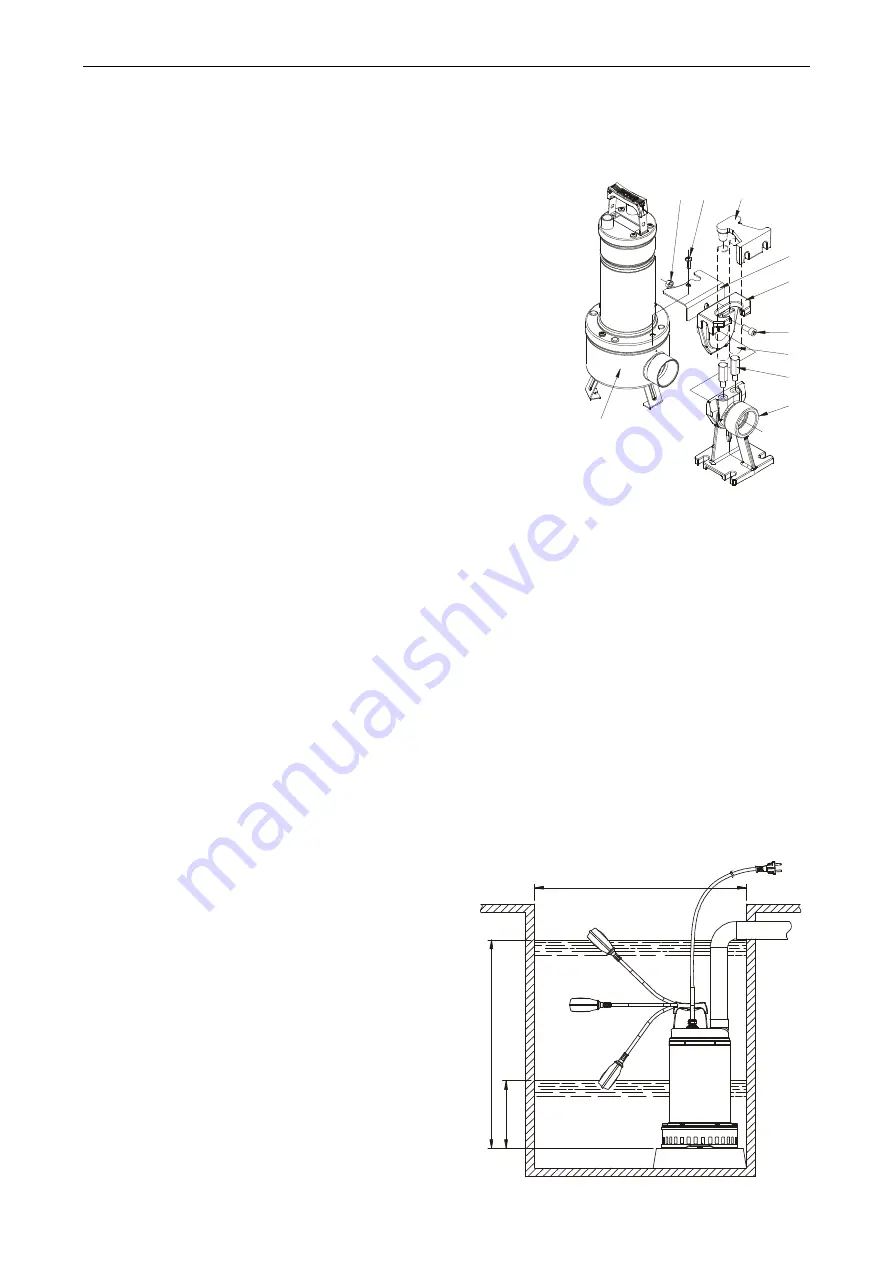

For fixed installations we advise the use of the lifting device

DSD2 (available on request -

Fig.2

) to facilitate pump

maintenance operations. When fitted between the pump

delivery aperture and the pipe, it avoids having to remove the

delivery pipe during maintenance jobs. The DSD2 device is

composed of 8 parts:

A.

Pipe anchoring bracket

B.

3/4" pipes (not supplied)

C.

Slide

D.

Pipe guide columns

E.

Foot

F.

Screw TCEI M10X25

G.

Base bracket

H.

Nut M10

I.

Pump flange screw

L.

Pump

(Fig.2)

The foot is positioned on the bottom of the tank and fixed with expansion screws of suitable

dimensions. The pipe guide bracket must be positioned at the top of well or borehole and

inserted in the end of two 3/4” pipes (not supplied), which act as a slide. The two pipes connect

the bracket to the foot. Position the base bracket in contact with the pump suction strainer near

the delivery aperture, secure everything to the strainer cover with the screws provaided to lock

the strainer cover.

Remove the top screw from the flange on the delivery side ( I ).

Assemble the anti-rotation bracket ( G ).

Replace the screw ( I ).

Extract the slide from the coupling foot and connect it to the delivery port of the pump.

Using the screw F and the nut H, fix the slide to the pump as indicated in the figure.

Reposition the slide/pump assembly on the foot (

Fig.2

).

INSTALLATION

DRENAG 1000-1200

1.

Connect the delivery pipe or hose directly to

the pump mouth. If the pump is used in fixed

installations it is advisable to connect it to the

pipe with a coupling so as to facilitate

disassembly and reinstallation. If a hose is

used, fit a threaded hosetail on the pump

mouth. Wrap the thread with suitable material

to ensure an effective seal (teflon tape or

similar).

2.

On the version provided with a float switch,

ensure that the float can move freely (SEE THE

PARAGRAPH ON ADJUSTING THE FLOAT

SWITCH). Ensure that the

minimum

dimensions

of the borehole are as in

Fig.3

.

The dimensions of the borehole must also be

calculated with relation to the quantity of water

arriving and to the pump flow rate so as not to

subject the motor to excessive starting

operations.

(Fig.3)

H

I

A

G

C

F

B

D

E

L

600x600

O

N

OF

F

Содержание DRENAG 1000-1200

Страница 89: ...59 5 2 5 3 99 6 6 1 IEC 364 6 2 CEI 64 2 6 3 7 7 1 99 100 101 30 20 GRINDER 1400 M 7 2 7 3 2 7 4...

Страница 95: ...65 2 A B C D B C D 3 A B B 4 A B C A B C 5 A B C A B C...

Страница 114: ...84 5 5 1 5 2 5 3 99 6 6 1 IEC 364 6 2 CEI 64 2 6 3 7 7 1 99 100 101 30 20 GRINDER 1400 M 7 2 7 3 2 7 4...

Страница 120: ...90 4 A B C A B C A A B C A B C...

Страница 133: ...103 GRINDER...