ENGLISH

Ensure that the stop level does not uncover the strainer.

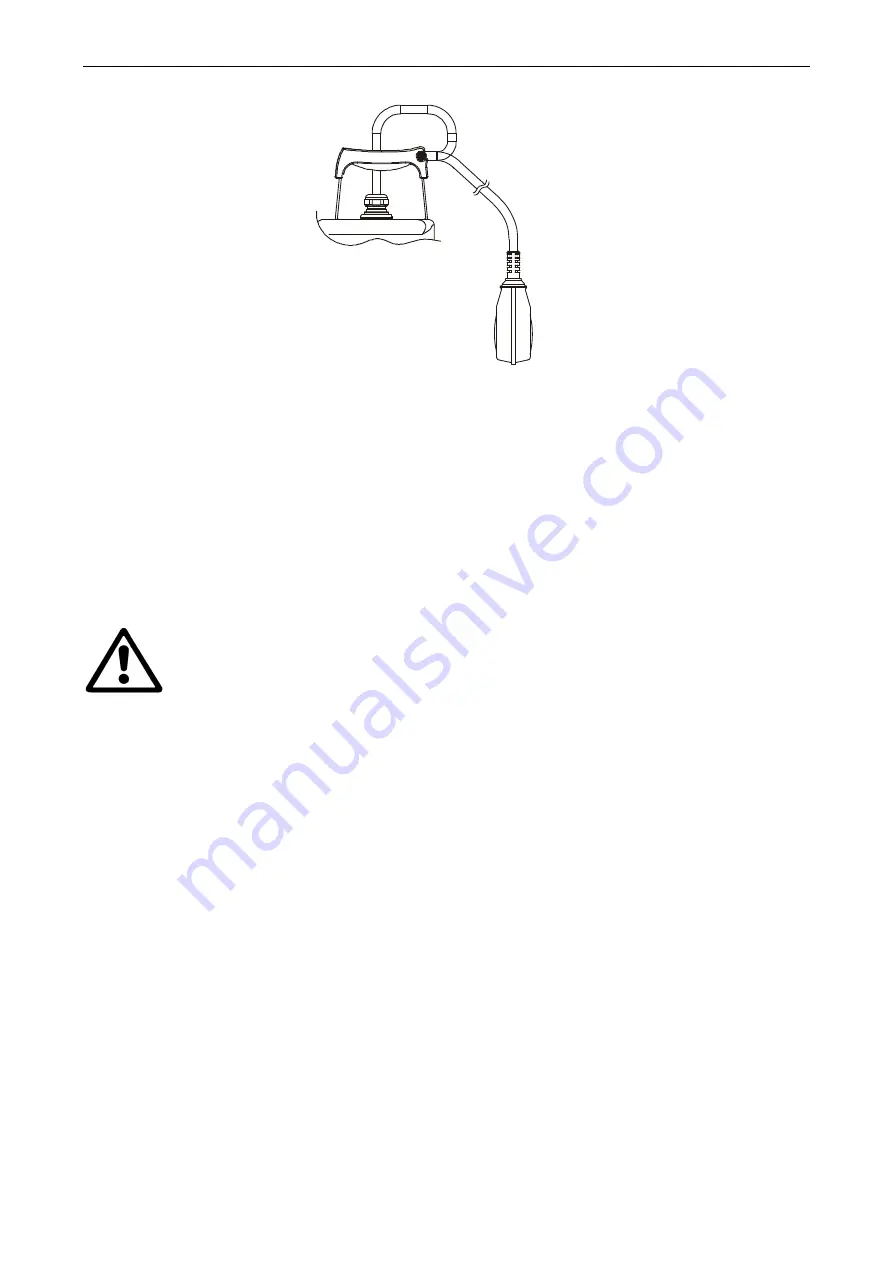

(Fig.5)

PRECAUTIONS

1.

The intake strainer must always be in place during pump operation.

2.

The pump should not be started more than 20 times in one hour so as not to subject the motor to

excessive thermal shock.

3.

DANGER OF FROST:

When the pump remains inactive for a long time at temperatures of less

than 0°C, it is necessary to ensure that there is no water residue which could freeze and cause

cracking of the pump components.

4.

If the pump has been used with substances which tend to form a deposit, rinse it after use with a

powerful jet of water so as to avoid the formation of deposits or scale which would tend to

reduce the yield of the pump.

MAINTENANCE AND CLEANING

In normal operation, the pump does not require any specific maintenance, thanks to its

mechanical seal lubricated in an oil chamber and to its sealed-for-life bearings.

The

electropump must not be dismantled unless by skilled personnel in possession of

the qualifications required by the regulations in force.

In any case, all repairs and

maintenance jobs must be carried out only after having disconnected the pump from the

power mains.

During disassembly, pay attention to any sharp parts which could cause injury.

Содержание DRENAG 1000-1200

Страница 89: ...59 5 2 5 3 99 6 6 1 IEC 364 6 2 CEI 64 2 6 3 7 7 1 99 100 101 30 20 GRINDER 1400 M 7 2 7 3 2 7 4...

Страница 95: ...65 2 A B C D B C D 3 A B B 4 A B C A B C 5 A B C A B C...

Страница 114: ...84 5 5 1 5 2 5 3 99 6 6 1 IEC 364 6 2 CEI 64 2 6 3 7 7 1 99 100 101 30 20 GRINDER 1400 M 7 2 7 3 2 7 4...

Страница 120: ...90 4 A B C A B C A A B C A B C...

Страница 133: ...103 GRINDER...