13

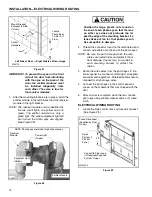

INSTALLATION—CONTROL PANEL AND ELECTRICAL CONNECTIONS

The fused disconnect must be in the OFF

position and the fuses removed before

wiring of the control box begins.

2.

Run wires from the encoder and motor to the control

box using approved conduit.

Coil Cord Installation

DO NOT twist the cord during installation.

Twisting the coil cord will cause it to tangle

or fail, leading to serious problems.

Ensure that the coil cord does not have

any excessive slack when installation is

complete. It should not touch the floor.

1.

Manually open the door. Allow the cord to hang

down to remove any twists in the cord.

2.

Route the coil cord to a junction box near the side

column and through the hole in the junction box.

3.

Place cord grip nut over the end of the coil cord. The

nut was shipped in the small parts carton.

4.

Tighten the nut to attach the cord grip to the junction

box.

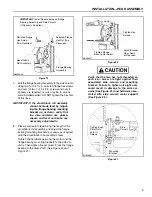

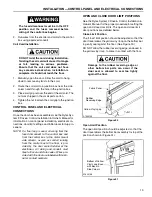

CONTROL PANEL AND ELECTRICAL

CONNECTIONS

Once the door has been assembled, see the Rytec Sys-

tem 3 Drive & Control Installation & Owner’s Manual for

information on control panel installation, electrical con-

nections, door limit settings, and initial door start-up pro-

cedure.

NOTE: If a floor loop is used, all wiring from the

fused disconnect to the control box and

from the control box to the motor mount

side column, as well as conduit running

from the control box to the floor, is pro-

vided by the door owner/installer or the

electrician. All wiring and conduit must

meet all local and state codes. Wires pro-

vided with the door are labeled with termi-

nal or contact numbers.

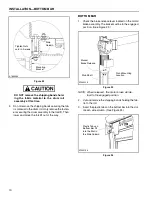

OPEN AND CLOSE DOOR LIMIT POSITIONS

See the Rytec System 3 Drive & Control Installation &

Owner’s Manual for the proper procedure for setting the

open and close door limits. The open and close limit

door positions are detailed below.

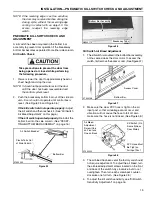

Close Limit Position

The “close” limit position should be adjusted so that the

door travel allows the yellow vinyl loop on the bottom bar

to gently seal against the floor. (See Figure 30.)

DO NOT allow the rubber reversing edge, enclosed in

the yellow vinyl loop, to come in contact with the floor.

Damage to the rubber reversing edge or

other bottom bar parts can occur if the

door seal is allowed to seal too tightly

against the floor.

Figure 30

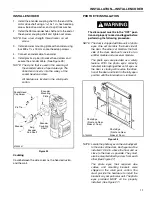

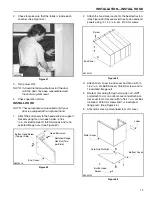

Open Limit Position

The open limit position should be adjusted so that the

door travel allows the bottom bar assembly to stop at the

position shown in (Figure 31.)

Figure 31

Yellow Vinyl Loop

Fabric Panel

Rubber

¹₂

–1 i

Reversing Edge

A7500195

A7500196

Bottom of Yellow

Vinyl Loop Even

with Bend in

Side Column

Содержание Pharma-Roll

Страница 1: ...Pharma Roll Installation Manual Revision January 15 2009 0715009 Rytec Corporation 2007...

Страница 2: ......

Страница 23: ...NOTES 19...

Страница 24: ......