36

REVT-05ERV

Spark Igniter

- A spark igniter is used to provide an

ignition spark for lighting the burners. The igniter is

mounted on the burner wrapper and is located above the

left-most burner as shown in

Figure 33

and can be easily

removed for service without removing any part of the

burners. During the ignition process, voltage is applied

to the Electrode, which arcs to Ground (

See Figure 34

)

creating a spark that ignites the left burner; which then

lights the adjacent burner and the flame travels from

burner to burner until all are lit.

The Spark Electrode is connected to the ignition control

by an 8 mm silicone-insulated, stranded, high voltage

wire. The wire uses a ¼" female quick-connect on the

electrode end and a female spark plug- type terminal on

the ignition control end.

NOTE: In order to maximize spark energy to the

Electrode, the high voltage wire should not touch

the cabinet unnecessarily.

Also, for proper operation, the Electrode to Ground gap

(spark gap) must be set correctly at 0.125 ± 0.015 inch

(3.2 ± 0.4 mm).

Flame Sensor

- A Flame Sensor (

Figure 35

) is located

on the right side of the Burner Rack Assembly directly

opposite the Spark Igniter (

Figure 33

) with the tip

protruding into the flame envelope of the right-most

burner. Like the Spark Igniter, the Flame Sensor can be

removed for service without removing any other part of

the Burner Rack Assembly.

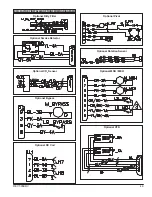

FIGURE 34 - SPARK IGNITER

FIGURE 35 - FLAME SENSOR

FIGURE 33 - BURNER RACK ASSEMBLY

FIGURE 32 - BURNER REMOVAL

When flame is sensed by the Flame Sensor (indicated

by micro-amp signal through the flame) the Spark Igniter

is de-energized immediately. During operation, flame is

sensed by current passed along the ground electrode

(located on the Spark Igniter), through the flame and into

the Sensor electrode. The Ignition Control allows the Gas

Valve to remain open as long as a flame signal (current

passed through the flame) is sensed.

Gas Valve (2-Stage and 5:1 Modulation)

- A two-stage

redundant valve (

Figures 18

) manufactured by White-

Rodgers. First-stage (low-fire) is quick opening (on and

off in less than 3 seconds), second-stage is slow opening

(on to high-fire pressure in 40 seconds and off to low-fire

pressure in 30 seconds). On a call for first-stage heat

(low-fire), the valve is energized by the ignition control

simultaneously with the spark electrode. On a call for

second-stage heat (high-fire), the second-stage operator

is energized directly. A manual switch is provided on the

valve, which closes both stages without delay.

Gas Valve (Split Manifold, 10:1 Modulation)

– Two

single-stage redundant valves (

Figures 18 and 21

)

manufactured by White-Rodgers. Both are quick

opening (on and off in less than 3 seconds). The valve

is energized by the ignition control simultaneously with

the spark electrode. A manual switch is provided on the

valve, which closes both stages without delay.

Combustion Air Inducer

- A combustion air proving

switch checks combustion air inducer operation before

allowing power to the gas control valve. Gas controller

will not operate if inducer is obstructed.

ELECTRODE

ELECTRODE

SPARK IGNITER

BURNER WRAPPER

INSHOT BURNERS

GAS REGULATOR VALVE

0.125±0.015

ROLLOUT SWITCH

FLAME SENSOR

ROLLOUT SWITCH

ORIFICES

MANIFOLD

GROUND

SPARK IGNITOR

BURNER RACK ASSEMBLY

INSHOT BURNER

BURNER SCREWS

BURNER SUPPORT

Содержание ENERVENT+ EVT-09 Series

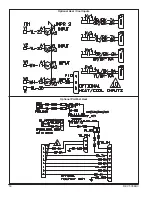

Страница 30: ...30 REVT 05ERV UNIT WIRING DIAGRAM ...

Страница 31: ...REVT 05ERV 31 UNIT WIRING DIAGRAM CONTINUED ...

Страница 47: ...REVT 05ERV 47 UNIT WIRING DIAGRAM XVIII WIRING DIAGRAMS ...

Страница 48: ...48 REVT 05ERV UNIT WIRING DIAGRAM CONTINUED ...

Страница 50: ...50 REVT 05ERV Optional Heat Cool Inputs Optional Pre Post Heat ...

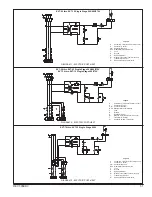

Страница 57: ...REVT 05ERV 57 DIAGRAM 15 5 1 MODULATION GAS POST HEAT DIAGRAM 14 2 STAGE GAS POST HEAT ...