16 REVT-05ERV

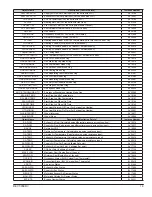

TABLE 3 - MINIMUM CFM WITH ELECTRIC POST-HEAT OPTION

C. ELECTRIC POST-HEAT

Post-Heat will stage on and cycle with thermostat

demand. Number of stages will vary depending on Post-

Heat assembly. See Post-heat wiring diagram on unit

for sequence of operation. Limit controls are factory-

set and are not adjustable. A minimum air volume must

be maintained through Post-Heat section per

Table 3

to

avoid tripping the limit during long periods of operation.

D. GAS POST-HEAT

Construction

- Heat exchanger is tubular construction.

Standard material is aluminized steel for all units except

the EVT-10 and EVT-12 where stainless steel is required.

Stainless steel is optional for all other units unless the

air temperature supplied to the heat exchanger is below

45°F, where it is required. Burners are inshot, aluminized

steel, with direct spark ignition and the gas valve is a

redundant automatic dual stage with manual shut-off.

Controls

- Ignition Control provides positive, direct

ignition of burners on each operating cycle. The system

permits main gas valve to stay open only when burners

are proven to be lit. Should flame loss occur, the gas

valve closes, shutting off the gas supply to the burners.

Ignition module has coded LED to indicate status and

aid in troubleshooting. Redundant limit controls are

factory installed with fixed temperature setting. Heat limit

controls protect heat exchanger and other components

from overheating. Flame roll-out switch, flame sensor and

combustion air proving switch protect system operation.

Available Selections

-

See Chart 4 on Page 46

for

available capacities and specifications by unit size.

Chart

5 on Page 46

lists performance data for all gas heat units.

E. MOTORIZED DAMPERS

Intake Air

- Damper mounts behind the outdoor air intake

hood. Opens when the ERV is energized and closes

when de-energized. Powered by B30 damper motor.

ELECTRIC POST-HEAT - REQUIRED MINIMUM AIR FLOW

UNIT

NON CFM MAX KW

NO

STAGES KW AVAIL MIN CFM

EVT-09

1,000

9.6

1

9.6

800

EVT-19

1,900

19.2

2

1

19.2

9.6

1,600

800

EVT-28

2,800

19.2

1

19.2

1,600

EVT-36

3,600

19.2

2

1

38.4

19.2

3,200

1,600

EVT-46

4,600

38.4

2

1

38.4

19.2

3,200

1,600

EVT-62

6,200

57.6

3

2

1

57.6

38.4

19.2

4,800

3,200

1,600

EVT-74

7,400

60

2

1

60

30

5,000

2,500

EVT-88

8,800

90

3

2

1

90

60

30

7,500

5,000

2,500

EVT-10

10,000

90

3

2

1

90

60

30

7,500

5,000

2,500

EVT-12

12,000

120

4

3

2

1

120

90

60

30

10,000

7,500

5,000

2,500

Exhaust Air

- Mounts between the exhaust blower and

the return air exhaust hood. Operates in conjunction with

Motorized Intake Air Damper. Powered by B31 damper

motor.

F. DIRTY FILTER SENSOR

Measures pressure drop across Intake and Exhaust

Filters and sends a signal to field wired alarm when filters

require maintenance.

G. FROST CONTROL

Extremely cold outdoor air temperatures can cause

moisture condensation and frosting on the energy

recovery wheel (ERW). The temperature below which

frost will begin to accumulate is referred to as the Frost

Threshold Temperature, and is a function of both outside

temperature and indoor relative humidity (

See Table 4

).

Frost formation causes reduction of airflow through the

ERW; therefore, without frost control, energy recovery

and airflow may be significantly reduced.

Frost control is an optional feature that will control wheel

frosting. Three frost Control options are available:

1. Exhaust Only

2. Variable ERW Speed

3. Electric Pre-Heat

FROST THRESHOLD TEMPERATURE (OD DB)

INDOOR

RH (%)

INDOOR DB TEMPERATURE

70

o

F

72

o

F

75

o

F

80

o

F

20

-14

-13

-11

-8

30

-3

-2

-1

3

40

5

7

9

11

50

13

13

15

18

60

18

19

21

26

Exhaust Only

- An exhaust temperature sensor value

will signal the controls to shutdown the supply blower

when the temperature in the exhaust quadrant reaches

a field adjustable temperature (Factory set 18°F). This

temperature can only be reached when the wheel is

frosted over. Normal operation resumes after a heat rise

of 16°F. To avoid depressurization of the conditioned

space, automatic or pressure operated fresh air dampers

may be required as part of the ventilation system.

Modulating Wheel Frost Control

- The modulating

wheel feature uses a variable frequency drive to modulate

the wheel’s speed based on outside air temperature. The

wheels RPM will slow as the temperature drops, hence

lowering the effectiveness of the wheel and preventing

icing up. The variable frequency drive is programmed to

have minimum frequency of 15hz so the wheel speed does

not interfere with the wheel rotation sensor’s operation.

Values in

Table 5

have been derived from the accepted

empirical model to allow entering supply air to remove all

water deposited on the wheel by the exhaust. This option

is best used for applications where the hours required for

frost control are limited.

Electric Pre-Heat

- This is the recommended method

of preventing frost formation while ensuring required

ventilation rates for most cold climate applications. A

constant air temperature, above the frost threshold, is

TABLE 4 - FROST THRESHOLD GUIDELINES

Содержание ENERVENT+ EVT-09 Series

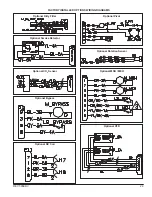

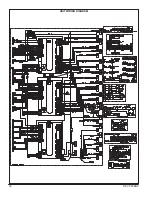

Страница 30: ...30 REVT 05ERV UNIT WIRING DIAGRAM ...

Страница 31: ...REVT 05ERV 31 UNIT WIRING DIAGRAM CONTINUED ...

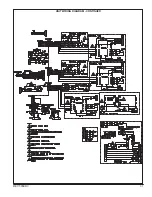

Страница 47: ...REVT 05ERV 47 UNIT WIRING DIAGRAM XVIII WIRING DIAGRAMS ...

Страница 48: ...48 REVT 05ERV UNIT WIRING DIAGRAM CONTINUED ...

Страница 50: ...50 REVT 05ERV Optional Heat Cool Inputs Optional Pre Post Heat ...

Страница 57: ...REVT 05ERV 57 DIAGRAM 15 5 1 MODULATION GAS POST HEAT DIAGRAM 14 2 STAGE GAS POST HEAT ...