REVT-05ERV 17

maintained entering the ERC by cycling a 2-stage electric

heat unit located just after the fresh air hood. The heater

is controlled by a field adjustable temperature sensor

located at the inlet of the wheel. If the temperature falls

below the setpoint the first stage will turn on. If that does

not satisfy the load, the second stage turns on.

See Pre-

Heat wiring diagram for circuit logic.

H. CO

2

SENSOR

Helps control indoor air quality based on CO

2

levels in

the occupied space. High CO

2

levels can either trigger

a response from the ERV unit by turning on the blowers

to bring in fresh air or by modulating the blowers if a

VFD option has been selected.

See Basic Unit wiring

diagram for circuit information.

I. ROTATION SENSOR

The circuit indicates the absence of pulses, within a

specified time range, provided by a magnetic sensor

detecting a magnet mounted on wheel surface. After the

initial time delay of approximately 5 seconds from circuit

power up, if the sensor fails to provide a signal pulse

(no wheel rotation) within approximately 5 additional

seconds, the alarm relay will activate the latch (until circuit

powers down) providing a 5 amp contact closure output.

This would indicate no wheel rotation and/or magnet in

the system has stopped at the magnetic sensor pickup

point. If the pulse (wheel rotation) is detected within the

approximately 5 second time period, the alarm relay will

remain open. No field timing adjustment of any type will

be required.

J. SMOKE DETECTORS

Duct mounted smoke detectors can be installed in both

return and/or supply air streams. Signals from the smoke

detectors can be set to start-up or shut-down the ERV unit

if smoke is detected.

See Basic Unit wiring diagram for

circuit information.

K. LOW AMBIENT KIT

Limits HVAC system operation when outdoor temperature

is below 10°F.

L. SENSIBLE-ONLY ERC

An Energy Transfer Wheel without the latent energy

transfer capability of the standard Enthalpy Wheel is

available for dry-climate application (RH less than 30%).

This wheel does not have the Silica Gel coating applied.

M. MERV 11 and 13 AIR FILTERS

All units are shipped with MERV 8 supply and exhaust

air filters. MERV 11 or 13 filters are available as factory

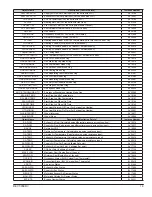

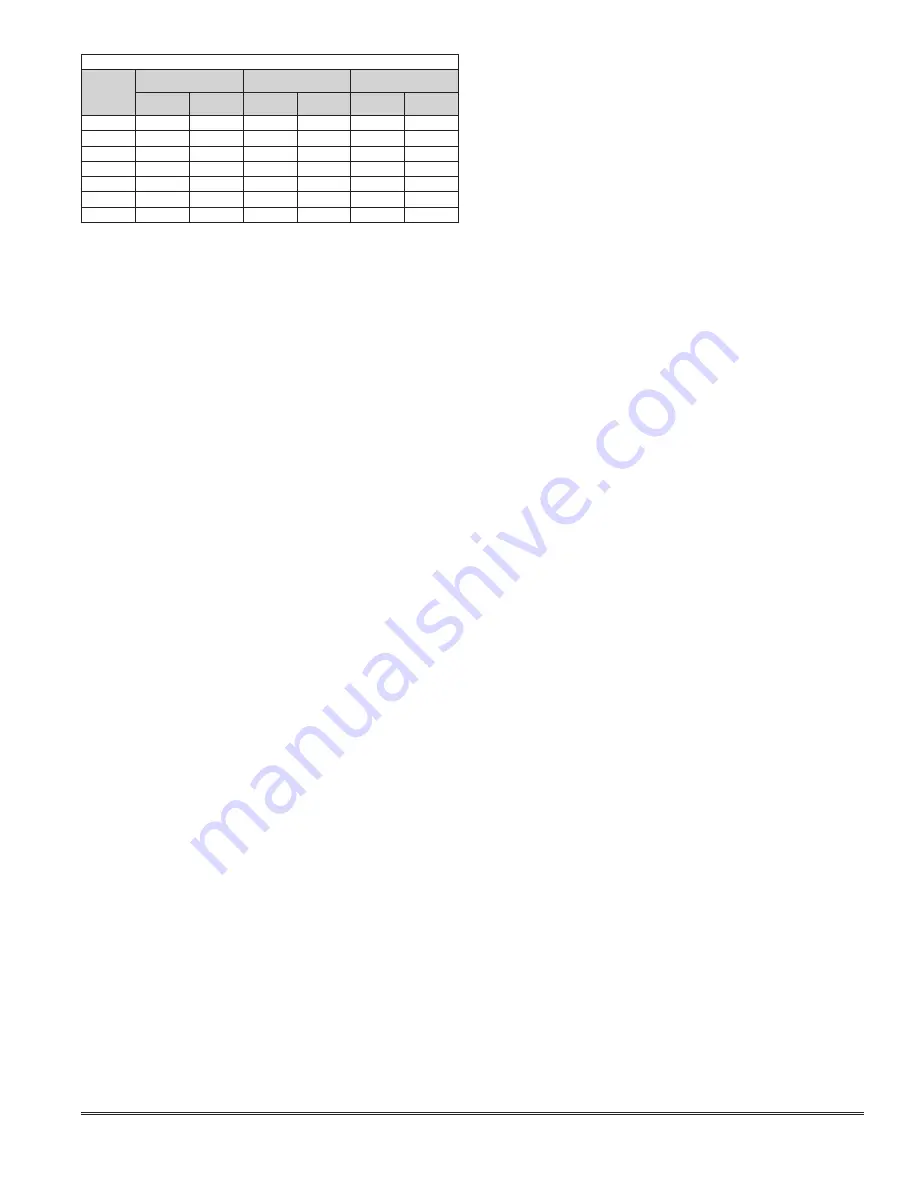

TABLE 5 - EXHAUST AIR LEAVING TEMPERATURE AND

ENERGY RECOVERY WHEEL EFFECTIVENESS

EXHAUST AIR TEMPERATURE AND ERW EFFECTIVENESS

ERW EFF

70

o

F AND 20% RH

INDOORS

70

o

F AND 30% RH

INDOORS

70

o

F AND 40% RH

INDOORS

DESIGN

TEMP

EAT

DESIGN

TEMP

EAT

DESIGN

TEMP

EAT

%

F

o

F

o

F

o

F

o

F

o

F

o

0.80

-13

4.0

-3

12.0

4

17.3

0.70

-15

11.0

-4.5

18.0

3

23.1

0.60

-19

17.0

-8

24.0

1

28.6

0.50

-26

22.0

-13

28.5

-3

33.5

0.45

-31

25.0

-17

31.0

-5

36.2

0.40

-40

26.0

-24

32.5

-10

38.0

installed options. MERV 8 filters are 30-35% efficient.

MERV 11 provides 60-65% efficiency at roughly the

same resistance level. The MERV 13 filter achieves the

minimum efficiency requirements (80-85%) of LEED

Green Building design. All are 2 inch thick, V-pleat design,

supported with expanded metal with Minimum Efficiency

Reporting Value determined per ASHRAE 52.2.

N. ELECTRONIC TEMPERATURE CONTROL

SYSTEM

Works in conjunction with optional heating and cooling

coils to temper the supply air back to ambient conditions.

Tempering the air entering the occupied pace allows

Enervent to bring in 100% outside air without putting an

additional load on the rooftop unit. The ETCS can be

entreated with a building automation system.

O. FREE AIR APPLICATION

Operation of the Energy Recovery Wheel can be altered,

sometimes referred to as Start, Stop, Jog, to take

advantage of economizer operation, which amounts to

free cooling. This is accomplished by:

De-energizing The ERC - Accomplished with a signal

from a Primary Temperature Sensor mounted in the air

intake compartment. This sensor will de-energize the

energy wheel when the outdoor air temperature falls

below the set point; which is factory set at 65°F, but is

field adjustable. An Override temperature sensor is

also furnished in the outdoor air intake compartment to

deactivate the economizer mode. This Override sensor,

also field adjustable, is factory set at 50°F; i.e., something

less that the Primary sensor. The two sensors together

create a deadband where the ERC will not operate and

free cooling can enter the building unconditioned.

P. GFCI SERVICE OUTLET

A 120 VAC GFCI service outlet is shipped loose for field

installation. Requires separate power source so power

is available when unit main disconnect is turned off for

servicing.

Q. EME INTAKE LOUVERS

A fresh air hood consisting of a built-in, louvered, moisture

eliminator requiring no maintenance during the life of the

unit. This contrasts with the standard hood, which contains

an aluminum mesh filter(s) requiring routine maintenance.

The EME intake surface is parallel to front of the unit and

extends outward approximately four inches.

R. VFD BLOWER CONTROL

Variable Frequency Drives (VFD) control the blower

speed. One VFD is provided for each blower (supply and

return), as well as the ERC if Modulating frost Control

is selected.. The VFDs provided are Johnson Controls

DC* line of drives manufactured by Eaton. Refer to the

Drive’s manual included with the ERV for further technical

specifications and information.

Refer to the VFD operation manual Chapter 5 for

information on parameters. Most manufactures setpoints

are retained except for :

P1 - Max Frequency - set to 60Hz

P2 - Min Frequency - set to 21.5 Hz

P7 - Operating Voltage - off motor nameplate

P8 - Motor AMPS - off motor nameplate

Содержание ENERVENT+ EVT-09 Series

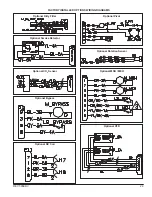

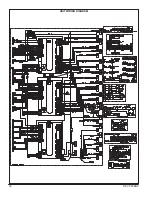

Страница 30: ...30 REVT 05ERV UNIT WIRING DIAGRAM ...

Страница 31: ...REVT 05ERV 31 UNIT WIRING DIAGRAM CONTINUED ...

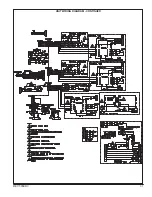

Страница 47: ...REVT 05ERV 47 UNIT WIRING DIAGRAM XVIII WIRING DIAGRAMS ...

Страница 48: ...48 REVT 05ERV UNIT WIRING DIAGRAM CONTINUED ...

Страница 50: ...50 REVT 05ERV Optional Heat Cool Inputs Optional Pre Post Heat ...

Страница 57: ...REVT 05ERV 57 DIAGRAM 15 5 1 MODULATION GAS POST HEAT DIAGRAM 14 2 STAGE GAS POST HEAT ...