BEFORE STARTING THE TOOL

Before starting-up the tool, ensure that:

- the packaging is complete and does not show signs of having been damaged

during storage or transport;

- the tool is complete; check that the number and type of components comply

with that reported in this instruction booklet;

- the power supply and socket outlet can support the load reported in the table

and that indicated on the tool identification plate reproduced;

- the power supply cable and plug are in perfect condition;

- the ON/OFF switch (2) works properly though with the power supply

disconnected;

- the wheel spindle locking button (4) is released (rotate the abrasive wheel by

hand for at least one revolution);

- all the parts of the tool have been assembled in the proper manner and that

there are no signs of damage;

- the ventilation slots (14) are not obstructed.

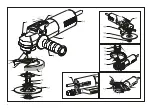

ASSEMBLING THE TOOL

DANGER:

never work without protective earmuffs (7)

Wear protective gloves!

- screw in the auxiliary handle (6); the handle can be mounted on the left or

right of the tool body;

- mount the dust brush (8) securely on the protective shield (7) (pushfit);

- mount the protective shield (7) with collar on the body of the tool using the

screws (10). Ensure that the protrusions on the collar (9) are inserted in the slots

cut into the flange of the adjustable protective shield (7);

- after tightening the screws (10) and collar (9), the adjustable protective shield

(7) must be able to rotate with a slight resistance approximately 20° in order

that it may be positioned as desired;

- connect the extraction device by the suction pipe in the nozzle (15).

The protective shield (7) must be mounted around the handle.

ASSEMBLY OF THE DISC HOLDER SANDING PAD AND THE

ABRASIVE DISC

1.Insert the disc pad (12) on the spindle (5);

2.fit the abrasive disc;

3.screw on the ring nut (11) and tighten it using the pin wrench (13) preventing

the spindle from moving with the 17 mmspanner or with the spindle locking

button (4).

11

Sound pressure level / Sound power level 3 axis vibration level

(Surface grinding)

)

LPA

LWA Uncertainty

ah Uncertainty

dB(A)

m/s

2

BA 31ES

90

101

3

5,50

1,50

INFORMATOIN NOISE / MEAN ACCELERATION VALUE

The tools are suppressed in accordance for the prevention and elimination of radio

disturbances measured in accordance with standard:

EN 60745

DANGER

The indicate measurements refer to new power tools.

Daily usa causes the noise and vibration values to change.

Displayed emission values are comparative and are to be employed for

a provisional assessment of the operator’s risk exposure during the work period.

Appropriate evaluation of work period must also include tool’s idle and stop

periods. These emission values represent the tool’s main applications.

If the tool is used for other applications, with other accessories, or if it does not

undergo regular maintenance, emission values can significantly increase

during operations.

Use hearing protection!

PARTS OF THE TOOL

1 - Technical data identification label

2 - ON/OFF switch

3 - Speed control

4 - Wheel spindle locking button

5 - Spindle

6 - Side handle

7 - Adjustable protective shield

8 - Dust brush

9 - Collar with protective shield fixing points

10 - Protective shield fixing screws

11 - Disc pad tapered ring nut

12 - Abrasive disc mouting plate

13 - Spanners

14 - Motor ventilation slots

15 - 29 mm Ø suction port

STARTING UP

WARNING

Pay attention to the mains voltage! The mains voltage must

correspond to the voltage indicated on the technical data identification

label (1).

DANGER

Before any intervention on the electrical tool take the plug

out from the socket

Содержание BA31ES

Страница 2: ...2...

Страница 33: ...33 33 ISO7010 W001 ISO7010 M002 ISO7010 M004 ISO7010 M003 ISO7010 M016 ISO7010 M009 EurAsian C Tick...

Страница 34: ...34 230 50 EPTA 01 2003 BA31ES II 900 1 500 4 000 115 M 14 2 1...

Страница 35: ...35...

Страница 38: ......

Страница 39: ......