Section 6 Maintenance

S7M / S8M Manual

www.rottlermfg.com

6-1

Maintenance

Lubrication

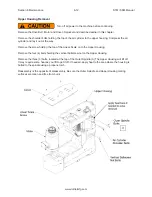

Refer to the illustrations on the following pages.

Horizontal Ballscrew Nut

The horizontal ballscrew nut is located under the Spindle base inside the Main Base.

• Every 175 hours, Grease the ball screw nut using

NLGI #2 White Lithium Grease

. Wipe a small

amount of grease on the screw just ahead of the nut.

Vertical Ballscrew Nut

The Vertical ballscrew nut is located in the Spindle base inside the cover.

• Every 175 hours, Grease the ball screw nut using

NLGI #2 White Lithium Grease

. Wipe a small

amount of grease on the screw just ahead of the nut.

Outer Spindle

The Outer Spindle is the cylinder that travels up and down. It is supported in outer spindle bushings.

• Every 40 hours, The Outer Spindle should be cleaned with

WD-40

. And occasionally

ISO VG 32

Hydraulic Oil

applied to prevent excessive dryness.

Inner Spindle

The Inner Spindle is located inside the Outer Spindle. The Inner Spindle is directly connected to the

cutterhead.

• Every 40 hours, Add 2 or 3 drops of

ISO VG 32 Hydraulic Oil

.

• Every 175 hours, Add one shot of

NLGI #2 White Lithium Grease

.

•

Run the spindle down near the lower limit and you will see a flush type grease fitting in the

spindle. Add lubrication here. If the inner spindle is removed clean the lower bearing and repack it

with grease.

Cleaning The Way Surface

Do not

clean way surfaces with abrasive or harsh cleaners, The sliding way material used under the

spindle base, must “break in” which will deposit a small amount of the material into the top of the main

base. Discoloration will occur in slides. If the way surface is cleaned of these deposits, the “break in”

action will start all over. If this cycle is repeated premature wear will result.

Lubrication – Quick Reference Chart

Assembly

Frequency

Lube Operation

Horizontal Ballscrew Nut

Every 175 hours

Grease ballscrew nut

Vertical Ballscrew Nut

Every 175 hours

Grease ballscrew nut

Outer Spindle

Every 40 hours

Clean and wipe with oil

Inner Spindle

Every 40 hours

Add 2 to 3 drops of oil

Inner Spindle

Every 175 hours

Add Oil

Way Surface

Every 175 hours

Wipe and oil way surface

Содержание S7M

Страница 2: ......

Страница 4: ......

Страница 8: ...Section 1 Introduction S7M S8M Manual www rottlermfg com 1 4 ...

Страница 17: ...Section 2 Installation S7M S8M Manual www rottlermfg com 2 8 ...

Страница 18: ...Section 2 Installation S7M S8M Manual www rottlermfg com 2 9 ...

Страница 38: ...Section 5 Operating Instructions S7M S8M Manual www rottlermfg com 5 9 ...

Страница 42: ...Section 6 Maintenance S7M S8M Manual www rottlermfg com 6 2 S7M S8M Machine Lubrication Illustration ...

Страница 57: ...Section 6 Maintenance S7M S8M Manual www rottlermfg com 6 17 Pneumatic Control Diagram ...

Страница 65: ...Section 6 Maintenance S7M S8M Manual www rottlermfg com 6 25 Inner Spindle Lower Section Bearing Section View ...

Страница 66: ...Section 6 Maintenance S7M S8M Manual www rottlermfg com 6 26 ...

Страница 68: ...Section 7 Troubleshooting S7M S8M Manual www rottlermfg com 7 2 ...

Страница 70: ...Section 8 Machine Parts S7M S8M Manual www rottlermfg com 8 1 Machine Parts Front Right Side View S7 8M ...

Страница 71: ...Section 8 Machine Parts S7M S8M Manual www rottlermfg com 8 2 Pneumatic Assembly ...

Страница 72: ...Section 8 Machine Parts S7M S8M Manual www rottlermfg com 8 3 Electrical Enclosure ...

Страница 74: ...Section 8 Machine Parts S7M S8M Manual www rottlermfg com 8 5 Upper Housing ...

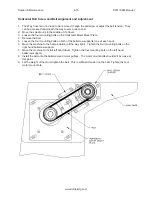

Страница 75: ...Section 8 Machine Parts S7M S8M Manual www rottlermfg com 8 6 Upper Vertical Travel Belt Parts ...

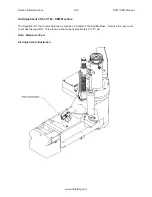

Страница 76: ...Section 8 Machine Parts S7M S8M Manual www rottlermfg com 8 7 Spindle Base Front Section ...

Страница 77: ...Section 8 Machine Parts S7M S8M Manual www rottlermfg com 8 8 Inner Outer Spindle Assembly ...

Страница 78: ...Section 8 Machine Parts S7M S8M Manual www rottlermfg com 8 9 Spindle Base Bushings ...

Страница 79: ...Section 8 Machine Parts S7M S8M Manual www rottlermfg com 8 10 Spindle Base Assembly ...

Страница 80: ...Section 8 Machine Parts S7M S8M Manual www rottlermfg com 8 11 Left Ballscrew Support ...

Страница 81: ...Section 8 Machine Parts S7M S8M Manual www rottlermfg com 8 12 Right Ballscrew Support ...

Страница 82: ...Section 8 Machine Parts S7M S8M Manual www rottlermfg com 8 13 Home and Limit Switches ...

Страница 83: ...Section 8 Machine Parts S7M S8M Manual www rottlermfg com 8 14 Pendant Assembly ...

Страница 84: ...Section 8 Machine Parts S7M S8M Manual www rottlermfg com 8 15 Spindle Base ...

Страница 85: ...Section 8 Machine Parts S7M S8M Manual www rottlermfg com 8 16 Chip Shield 14 16 ...

Страница 86: ...Section 8 Machine Parts S7M S8M Manual www rottlermfg com 8 17 14 Fly Cutter ...

Страница 87: ...Section 8 Machine Parts S7M S8M Manual www rottlermfg com 8 18 Chip Chute ...

Страница 88: ...Section 8 Machine Parts S7M S8M Manual www rottlermfg com 8 19 Waycovers and Optional Chip Catcher Assembly ...

Страница 89: ...Section 8 Machine Parts S7M S8M Manual www rottlermfg com 8 20 Riser Set ...

Страница 90: ...Section 8 Machine Parts S7M S8M Manual www rottlermfg com 8 21 Air Diagram ...

Страница 92: ...Section 9 Options S7M S8M Manual www rottlermfg com 9 2 ...

Страница 94: ...Section 10 Material Data Safety Sheets S7M S8M Manual www rottlermfg com 10 2 ...

Страница 95: ...Section 10 Material Data Safety Sheets S7M S8M Manual www rottlermfg com 10 3 ...

Страница 96: ...Section 10 Material Data Safety Sheets S7M S8M Manual www rottlermfg com 10 4 ...