- 5 -

www.rotork.com www.remotecontrol.se

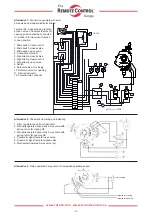

Adjustment of the Indicator Bridge

After the actuator has been mounted on the valve, the in

-

dicator bridge must be synchronized to the valve ends, not

only to get the latches to mesh and get indications of sig

-

nals, but also in order to prevent damages to the bridge.

The actuator is normally delivered with the gear wheel

(3:S1/52) unmounted, see figure 6. If the actuator is

delivered mounted on a valve, the bridge mechanism and

indicating switches will be preset before dispatch.

Figure 7

3:S1/41

3:S1/9-10

3:S1/14

4

3

2

1

Figure 6

3:S1/52

3:S1/7-8

Indicator Bridges 175S, 100S and 050S

These indicator bridges will be delivered without the

screw (3:S1/31), and the bridge turned so that the bridge

gears (3:S1/48 and GDS1:1+GDD2:1/5) do not mesh.

The bridge is fastened by screws in place, after the valve

is closed entirely and the instructions given for the types

175, 100 and 050 above have been carefully observed.

The actuator is now synchronized to the valve. Should the

actuator ever be removed from the valve, synchronization

must be checked after re-installation.

The bridge is just an indicating and control device and is

not intended to ”stall out” the actuator.

Indicator bridge 175, 100 and 050

1. Remove the cover.

2. Close the valve entirely.

3. Undo the two stops No. 1 & 2 closed to the slide block

(3:S1/9-10), so that it can move freely within the whole

range. Figure 6 shows the adjustment of the stops.

Damage could occur if the slide block runs against the

stops 1 & 2 moving them more than 3,2 mm.

4. Make sure that the slide block stands close to the

bracket (3:S1/14), so that there is space enough on

bridge spindle for valve to open, figure 7.

5. Bring over the shaft (3:S1/41) about 3 mm against

bracket (3:S1/14), so that the latch (3:S1/26) figure 2,

is turned in a suitable position to grasp the catch

(2:S1/12). Suitable tool: Seeger circlip pliers.

6. Bring the stop No.1 between the slide block and the

bracket (3:S1/14) towards the slide block and screw on

tightly.

7. Put the bridge gear (3:S1/52) in place.

8. Open the valve entirely, and check that the slide block

can move freely within the whole range, figure 3 shows

the slide-block (3:S1/9-10) in open valve position.

9. Bring over the shaft (3:S1/41) in the opposite direction

(about 3 mm) and fasten the stop No.2 by screws after

having been brought towards the slide block.

10. Adjust the other two stops, (3 & 4), so that the micro-

switches are actuated at the end positions of the valve.

11. Fit the cover and tighten the screws.

Risk for injuries caused by crushing/squeezing and

electrical shocks when the actuator is energized by air

pressure and electricity with its cover off. Before open

-

ing, check that the compressed air and possible power

supply are disconnected. The cover should be mounted

when the actuator operates.

WARNING!