- 8 -

Ref No 661C / Art No 980661

www.rotork.com www.remotecontrol.se

ROTORK SWEDEN AB

Box 80, Kontrollvägen 15, SE-791 22 Falun, Sweden

Tel: +46 (0)23-587 00 • Fax: +46 (0)23-587 45 • [email protected]

We reserve the right to

make changes without notice

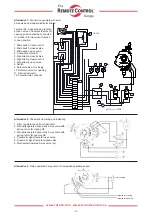

Pos 3

Pos 2

Pos 1

A

D

C

B

1. Make sure that the valve is fully closed.

2. To adjust the limit switches, the position transmitter need to

be dismounted. If limit switches are not used, please continue

at point 13.

3. Dismount the position transmitter by unscrewing the two

screws holding the connection terminal in the box. Move the

connection terminal sideways with the cables still attached. Pull

the position transmitter carefully straight out until it is released.

4. Attach suitable indication equipment to the limit switches in the

box indicating the closed and open position (view wiring dia-

gram sent with the box).

5. In cases where visual indication is used, turn the input shaft

of the gearbox (Figure B) to the position where the red indicator

points at closed position, i.e. 0%.

6. Adjust the cam of the limit switch indicating closed position by

loosening the socket head cap screw (Figure D pos. 3) and

turning the cam anti-clockwise to the position where the limit

switch starts to indicate. Fasten the cam in this position.

7. Mount the gear on the input shaft of the gearbox in the way that

it is free to rotate without touching the hub of the actuator. Mark

the position of the gear with a marker.

8. Rotate the gear clockwise the number of turns the valve need

to open, times two. 10.25 turns of the valve gives 20.5 turns of

the gear etc.

9. Adjust the cam of the limit switch indicating open position by

loosening the socket head cap screw (Figure D pos. 3) and

turning the cam clockwise to the position where the limit switch

start to indicate. Fasten the cam in this position.

10. In cases where visual indication is used, the hand should now

be pointing at open position, i.e. 100%.

11. Rotate the gear anti-clockwise back to the exact closed posi-

tion and check the number of turns of the valve.

12. Make sure that the marks on the backside of the position

transmitter are lined up (Figure A). Put the position trans-

mitter back into the box by pushing its shaft into the O-ring

provided hole in the shaft of the box. Remount the terminal

block and check that the position of the position transmitter has

not changed.

13. The position transmitter shall be adjusted with its marks lined

up (Figure A) and possible limit switches and visual indication

shall show closed position.

14. Attach suitable indication equipment to the position trans-

mitter and possible limit switches (view wiring diagram sent

with the box).

15. Adjust the output signal from the position transmitter for

closed position (i.e. 4.00 mA) by turning the screw underneath

the protection plug marked with ”ZERO” on the position trans-

mitter (Figure A). Use a small flat screwdriver.

16. See point 7.

17. Rotate the gear clockwise to the position where the limit

switch indicate open position. In cases where limit switches are

not used, see point 8.

18. Adjust the output signal from the position transmitter for open

position (i.e. 20.00 mA) by turning the screw underneath the

protection plug marked with ”SPAN” on the position transmitter

(Figure A).

19. Repeat point 15 and 18 a couple of times until a stable output

signal is received from the position transmitter.

20. Rotate the gear to closed position and mount it according to

Figure C.

21. Try to manually operate the actuator and check the signals.

Complete adjustment of box 1990

The limit switches are the primary indication of the

box. In cases where limit switches are not used, the

position transmitter of the box is the primary indica-

tion. In cases where visual indication is used, caution

shall be taken to avoid the indicator to exceed the

endpoints of the scale in any occasion. If this happens

the indicator and the through shaft can be damaged.