ENGLISH

13

Setting the off-set:

press the “+“ and “-“ button at the same time. The heater element can

subse-quently be calibrated using one of these buttons and an external temperature

measuring instrument.

If the heater element displays a smaller value than that on the external temperature measuring

instrument then the difference must be adjusted using the “+“ button. For indicated values in

the other direction adjust the difference using the “-“ button. If “Er1“ appears it means that the

elec-

tronics are defective. “Er2“ means that the resistance thermometer is defective or not

connected.

Very hot

– Do not touch! The heating element can reach a temperature of

approx.290°C!

3.2.2 Preparations for welding

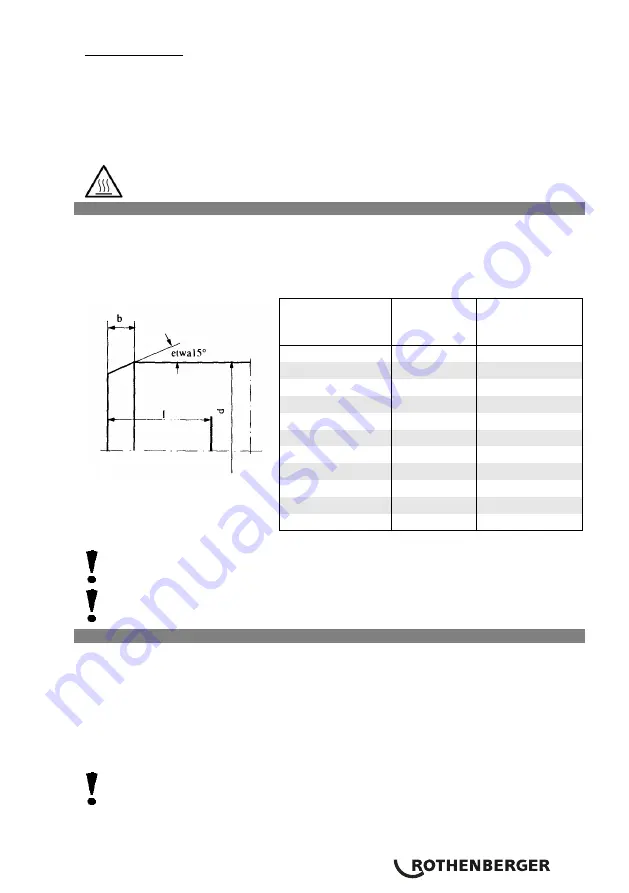

The end of the pipe is to be chamfered as shown in

fig 1

and set out in

Table 1

.

The connection area of the pipe is to be machined as specified by the manufacturer of the

shaped piece.

Make the insertion depth at the end of the pipe over a distance as set out in table 1.

The inside of the shaped piece is to be cleaned thoroughly with a degreasing agent

(for example methylated spirits) and a non-fibrous paper.

Check weather conditions!

3.2.3

Welding

Move the pipe and shaped piece quickly and axially to the mark on the heating arbour and

jack fitted on the heating element and fix them in place.

Keep them secure for the heating time as shown in tables 2-4.

After the elapse of the heating time, pull the pipe and shaped pipe out of the heating

arbour and jack quickly and push them together up to the mark immediately without

turning them (positioning time shown in tables 2-4).

Hold the connection tight for the time shown in tables 2-4 and then allow it to cool.

The weld must not be stressed by further installation work until after the elapse of

the cooling time!

After each weld the heating arbour and jack should be cleaned with non-fibrous paper

and, if necessary, methylated spirits.

Pipe diameter

Pipe chamfer

Insertion depth

PE, PP, PVDF

PE, PP, PVDF

PE, PP, PVDF

d (mm)

b (mm)

l (mm)

16

2

13

20

2

14

25

2

16

32

2

18

40

2

20

50

2

23

63

3

27

75

3

31

90

3

35

110

3

41

125

3

46

fig 1

Table 1

Содержание ROWELD HE

Страница 1: ...Bedienungsanleitung Instructions for use ROWELD P 125 ROWELD P 125 www rothenberger com 55546 55321 ...

Страница 2: ...A Overview 6 1 4 5 3 9 2 10 7 8 ...

Страница 18: ...16 7 Schaltplan Wiring diagram ...

Страница 20: ...18 Handgriff mit Elektronik handle incl electr no 1200001064 i2 1200001073 i2 ...

Страница 23: ...21 NOTES ...