Содержание Posidapt Expert

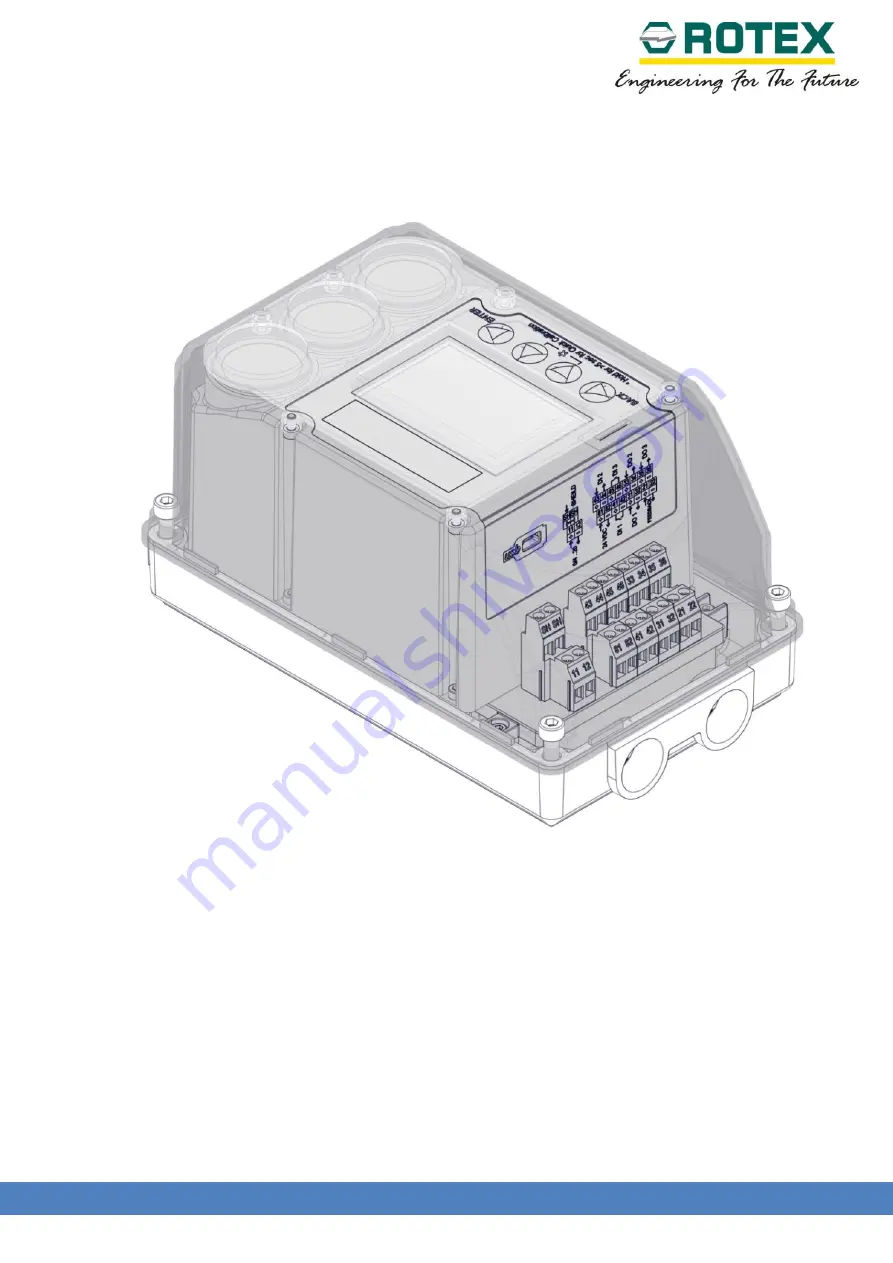

Страница 7: ...RTX IOM PRODUCT YY Page 7 of 131 www rotexautomation com 1 2 Posidapt Series...

Страница 17: ...RTX IOM PRODUCT YY Page 17 of 131 www rotexautomation com 4 Bock Diagram...

Страница 18: ...RTX IOM PRODUCT YY Page 18 of 131 www rotexautomation com 5 Dimensional Drawing...

Страница 30: ...RTX IOM PRODUCT YY Page 30 of 131 www rotexautomation com Figure 7 Attaching coupling and bracket to positioner...

Страница 44: ...RTX IOM PRODUCT YY Page 44 of 131 www rotexautomation com 7 Electrical Connection...

Страница 45: ...RTX IOM PRODUCT YY Page 45 of 131 www rotexautomation com 8 User Interface 8 1 Menu Structure Posidapt Expert...

Страница 46: ...RTX IOM PRODUCT YY Page 46 of 131 www rotexautomation com...

Страница 79: ...RTX IOM PRODUCT YY Page 79 of 131 www rotexautomation com...

Страница 122: ...RTX IOM PRODUCT YY Page 122 of 131 www rotexautomation com...