12

RAK283f

ENGLISH

FRANÇAIS

OPERATING INSTRUCTIONS

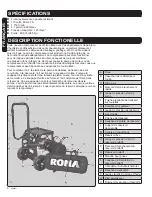

FASTENER DEPTH

The depth to which a fastener is driven is controlled by the depth adjustment (A). The

depth drive is adjusted to the maximum setting by the factory.

TO ADJUST

1. Loosen Screw (B), slide the adjustment to the desired position and retighten the

locking screw.

NOTE:

Sliding the safety bracket (A) upward increases the depth of the drive.

Sliding the safety bracket (A) down decreases the depth of the drive.

2. Test fire another fastener in a scrap work piece and check the depth.

REPEAT AS

NECESSARY UNTIL DESIRED DEPTH IS ACHIEVED.

The amount of air pressure

required will vary depending on the size of the setting. To determine the lowest

setting that will consistently perform the job at hand. Air pressure in excess of that

required can cause premature wear and/or damage to the tool.

3. A rubber nose cushion (C), is provided to reduce marring of the work surface. The

rubber cushion can be removed to increase the depth of the drive.

CAUTION:

Disconnect tool from the air supply before removing or installing the rubber

cushion.

Don’t use the tool without nails in the magazine. When there are only two or three nails

left in the magazine, the tool may misfire. It is not necessary to take the nails out. Simply

place a new strip of nails in the magazine and operate normally.

MAINTENANCE

CLEARING A JAMMED FASTENER

CAUTION:

Disconnect the tool from the air supply.

1. Remove any remaining fasteners from the nailer.

a. Pull feeder all the way to the rear until it latches

b. Slide the fasteners to the rear, and remove fasteners from the magazine

2. Use a pair of needle nose pliers and/or a flat screwdriver to remove bent fasteners

from the back of the nosepiece. If fastener cannot be removed as described, it may

be necessary to disassemble the magazine as follows:

a. Remove three screws (RAK283f-68 & RAK283f-65 on the left front of the

magazine and remove screws RAK283f-35 on the right front.

b. Remove support (RAK283f-73)

c. Slide the magazine back, off the nosepiece.

d. After clearing bent fastener, reassemble in reverse order.

REGULAR MAINTENANCE

Clean and inspect the tool daily. Make sure the tool is disconnected from the air

supply.

Blow the tool clean with compressed air and inspect for wear or damage. Use

non-flammable cleaning solutions to wipe the exterior of the tool only if necessary.

DO NOT SOAK tool with cleaning solutions. Such solutions can damage internal

parts.

Inspect the trigger and the safety mechanism to assure the system is complete and

functional. Check for loose or missing parts, and any parts that may be sticking.

Keep all the screws tight. Loose screws may cause personal injury.

Place two or three drops of pneumatic oil (included) into the air inlet of the tool daily.

A

B

C

!

!

Fig. 5