- 9 -

OPERATION

WARNING

–

Your safety and the wellbeing of others during the operation of every

ROLAIR

®

compressor is our main

concern. Do not operate or permit anyone else to operate your air compressor until the information contained in this

manual is read and completely understood. Please contact your distributor or our customer service department if you

have any questions on the proper use of your air compressor.

DIRECT-DRIVE ELECTRIC

Establish that the air compressor is ready to operate by reviewing the topics and information provided in the

“Pre-Start Checklist” section of this manual. Slowly open tank drain to remove any condensate that has accumulated

and keep drain open for a few seconds after starting to warm up motor/pump assembly. Make sure the pressure

switch lever is in the “Off” position before plugging power cord into a properly grounded outlet. Move pressure

switch lever to the “On/Auto” position to build and automatically maintain top end tank pressure setting. Rotate

regulator adjustment knob counterclockwise until the gauge attached reads 0 PSI before attaching air hose and

accessory. Set working pressure by rotating regulator adjustment knob clockwise and lock in working pressure

according to specifications provided by the tool manufacturer. Always use the pressure switch “On(Auto)/Off” lever

to start or stop the air compressor. Never stop the compressor by unplugging it from the power source. Store

compressor in a warm/dry location and perform maintenance as indicated in manual.

BELT-DRIVE ELECTRIC

START/STOP OPERATION:

Follow same procedures described above for use of direct-drive

electric compressors. Open drain valve located on pump aftercooler for

cold starting purposes. An electric belt-driven motor should not be

subjected to more than 15 starts per hour. Consult your dealer or any

authorized

ROLAIR

®

service center for information on a conversion kit if you

experience nuisance tripping of the motor overload due to an excessive

amount of motor starts per hour.

CONSTANT-SPEED OPERATION:

Constant speed or continuous-running operation should be used

during periods of heavy use to extend motor life and prevent overheating.

If your machine is built to only operate continuously, special care must

be taken to safely start and stop the machine. Always shut off the

power to the electrical outlet at the main breaker or optional on/off

switch before plugging in or unplugging the power cord. We also highly

recommend complete draining of storage tank(s) and opening of aftercooler drain valve prior to starting, especially

when operating in cold temperatures. Never stop the compressor by pulling the plug from the outlet. Use the

breaker or optional on/off switch to shut off the power to the outlet first.

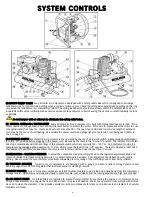

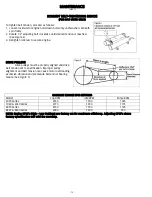

DUAL-CONTROL OPERATION:

Dual controls allow an easy transition between start/stop and continuous-running operation. See figure 1 for

instructions to switch operation from start/stop to constant speed. Always flip the lever on the pressure switch to the

“off” position before plugging in or unplugging the power cord.

DUTY CYCLE:

All

ROLAIR

®

belt-driven air compressors are equipped with S1 or 100% duty cycle motors and pumps. Given

proper ventilation and electrical power, your ROLAIR

®

compressor is capable of operating continuously when set up

for constant speed operation. However, an excessive amount of starts per hour may generate enough heat to trip the

motor overload. Please contact our factory Customer Service Department if overload problems repeatedly occur.

Several

ROLAIR

®

direct-drive machines, Models FC1500HBP2, FC1500HS3 and JC10, are rated for 70% duty

cycle. If subjected to continuous operation the internal overload will shut down the motor and only restart when

sufficient cooling has occurred.

GAS POWERED

Refer to item numbers 12, 16, 17 & 18 in the “System Controls” section of this manual for information on the

engine automatic idle control, kill switch, choke and fuel shut-off valve. Also note the engine throttle arm is locked

into a top RPM setting that will provide maximum service life and does not need to be moved to start or stop the

machine. Additional instructions can be found in the engine owner’s manual. Use the drain valve located on the

pump aftercooler or intercooler for cold-starting purposes. Take additional care to keep dirt/debris from entering the

fuel tank or obstructing the air flow through the engine or past the pump. Make sure the air flow to the regulator is

completely closed (gauge attached reads 0 PSI) before attaching air hose and accessory. A slight

hissing noise caused

by the air flow being directed to atmosphere during engine idle is normal. Store compressor in a warm/dry location

and perform maintenance as indicated in your manuals.