- 8 -

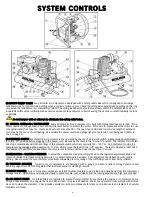

PRE-START CHECKLIST

Read the owner’s manual thoroughly. Make sure that you completely understand all of the safety warnings,

system controls and instructions provided before attempting to operate this air compressor. Every effort has been

made to provide you with the information needed to obtain many years of reliable and trouble-free service out of

your new air compressor. It is your responsibility to operate the air compressor properly. To obtain the longest

possible service life from your air compressor you must always keep the following instructions in mind.

1.

ALWAYS OPERATE THE COMPRESSOR IN A LEVEL POSITION

All splash-lubricated pumps have a dipper on the bottom of the connecting rod that must remain submerged in

the oil bath. Operation at more than a 10 degree angle will cause the pump to seize and void the product

warranty

2.

OPERATE IN A CLEAN, DRY AND WELL VENTILATED AREA

Allow at least 18” behind the belt guard for proper cooling of pump from flywheel blast. Do not operate in the rain

or in areas of standing water. Never operate in an area where other gases, fumes or vapors are present which

may become explosive when compressed. Do not operate compressor in an enclosed area.

3.

CHECK OIL LEVEL DAILY AND CHANGE AT REGULAR INTERVALS

Refer to the maintenance section of this owner’s manual for the correct type/weight of oil to use and how often

the oil should be changed. Check oil levels daily.

4.

INSPECT/CLEAN/CHANGE INTAKE ELEMENTS ON A REGULAR BASIS

The ingestion of dirt into the pump and engine is the primary cause of premature wear. Pay special attention to

the intake filters. Check intake filters daily.

5.

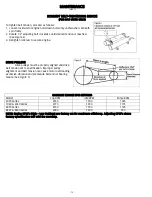

USE LONGER, PROPERLY SIZED AIR HOSE RATHER THAN EXTENSION CORDS

If an extension cord must be used, please refer to the chart below for the proper gauge and maximum length that

can be used. The use of inadequately sized air hose will also lead to frictional pressure drops that could affect the

proper performance of your air tools.

6.

DO NOT USE A GENERATOR AS THE POWER SOURCE

Air compressors use inductive motors that require 3-5 times the full-load amp draw to properly start. Most

generators will not provide the wattage needed to properly start this type of electric motor.

7.

CHECK TENSION OF BOLTS, BELTS, AND HARDWARE ON A REGULAR BASIS

Operation of any equipment with loose bolts and/or fittings will lead to excessive vibration

and the premature failure of the compressor system control components.

8.

MAINTAIN RUBBER VIBRATION PADS

Excessive vibration is a major cause of premature compressor failure. Always maintain the rubber vibration pads

located beneath tank assembly. Operation without them will void your warranty.

9.

DRAIN MOISTURE FROM AIR TANKS DAILY

Water is a natural byproduct of compressed air. Drain air tank(s) after each use to combat internal tank corrosion.

Keep drain valve(s) closed if storing compressor for any length of time.

ELECTRIC EXTENSION CORD TABLE

Minimum Wire Size

Extension

Cord Length

Motor

1/2 and 3/4 HP

Motor

1, 1-1/2, and 2 HP

Up to 25 ft.

14 Ga.

12 Ga.

25 – 50 ft.

12 Ga.

10 Ga.

50 – 100 ft.

10 Ga.

8 Ga.

10.

DO NOT ALTER FACTORY RPM SETTINGS ON GAS-POWERED COMPRESSORS. Engine throttle arm is factory set

and locked into position at RPMs that will provide maximum performance, fuel consumption and service life.

Alterations to this setting will void your warranty.