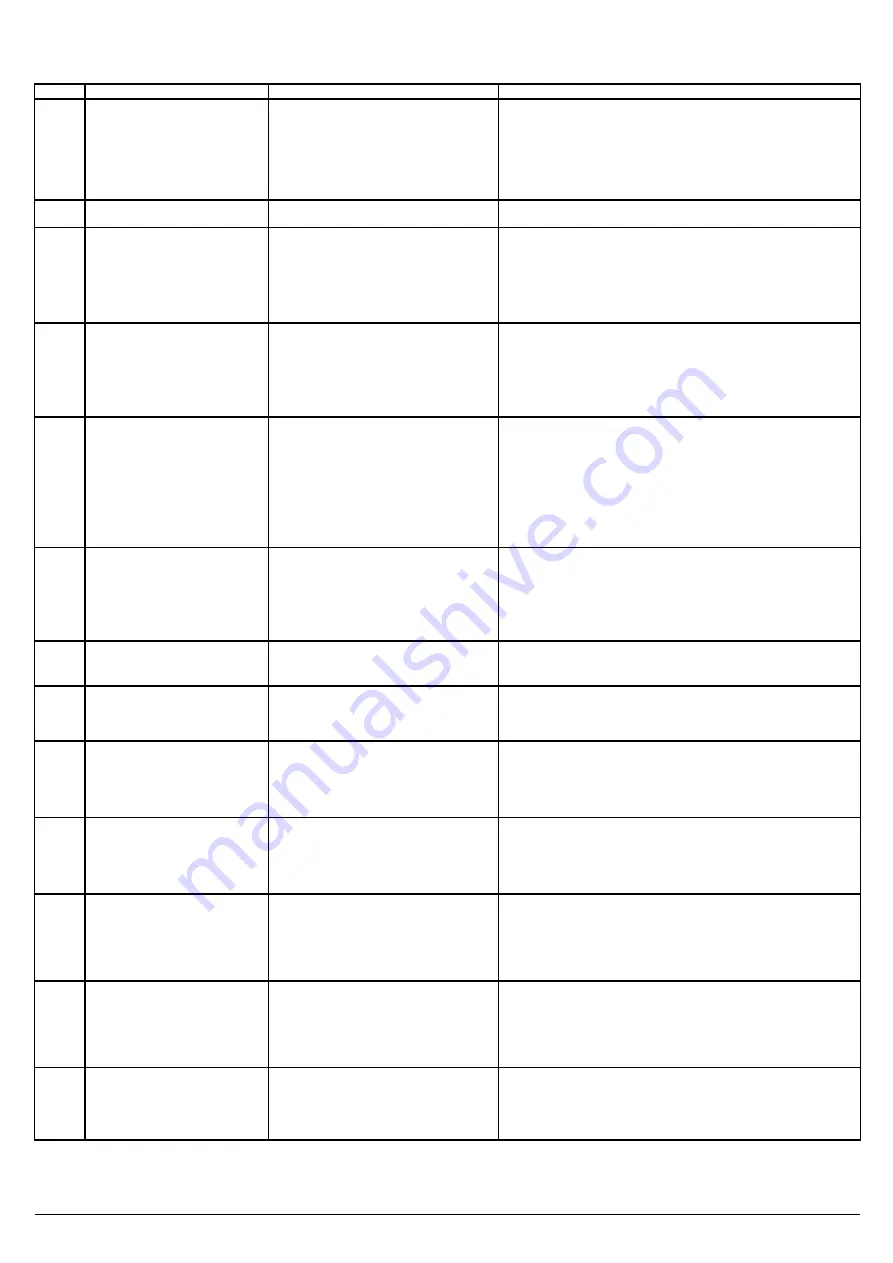

6-18 SERVICE CALL

CODE

EXPLANATION

ACTION

0002

Disorder of communication with

Sub CPU

This occurs when the Sub CPU is

not detected after turning on the

machine

Check cable connection between Main Board and Servo Board.

Check the other cable connections of Servo Board.

Servo Board replacement

Main Board replacement

Flexible cable replacement

0004

Sub CPU SRAM error

Servo Board replacement

0005

An error occurs during

downloading a program for sub

CPU.

Check cable connection between Main Board and Servo Board.

Check the other cable connections of Servo Board.

Servo Board replacement

Main Board replacement

Flexible cable replacement

0006

An error occurs when trying to

connect with sub CPU.

Check cable connection between Main Board and Servo Board.

Check the other cable connections of Servo Board.

Servo Board replacement

Main Board replacement

Flexible cable replacement

0007

An error occurs while sending a

command.

Check cable connection between Main Board and Servo Board.

Check the other cable connections of Servo Board.

Servo Board replacement

Main Board replacement

Flexible cable replacement

0008

There is a problem with

synchronizing serial

communication to Sub CPU.

Check cable connection between Main Board and Servo Board.

Check the other cable connections of Servo Board.

Servo Board replacement

Main Board replacement

Flexible cable replacement

0010

Network I/F Initialize has not

been completed.

Check the firmware is installed into Network I/F.

Main Board replacement

0101

Limit Position Initialize in the

Service Mode has not been

done.

Complete Limit Position Initialize correctly.

0102

Head Lock Sensor is ON when it

should be OFF, or vice versa.

Head Lock Sensor replacement

Check the mechanical backlash or loose with the scan axis related

parts.

0103

Limit Sensor is ON when it

should be OFF, or vice versa.

Limit Sensor replacement

Check the mechanical backlash or loose with the scan axis related

parts.

0105

Tool Carriage Connection Error

Check the mechanical Backlash or loose with the Tool Carriage

part.

Connection Part Replacement

Limit Position Initialize

0106

Machine fails to disconnect the

Tool Carriage from the Head

Carriage.

Check the mechanical Backlash or loose with the Tool Carriage

part.

Connection Part Replacement

Limit Position Initialize

0107

Linear Encoder Setup has not

been done.

Carry out Linear Encoder Setup in service menu.

Linear Encoder Setup has not been done.

Linear Encoder Setup is ended before it is

completed.

Network I/F does not work correctly.

Firmware for Network I/F is not installed.

Limit Position Initialize has not been done.

Limit Position Initialize is ended before it

is completed.

Head Lock Sensor does not work correctly

or is broken.

Head Carriage is not located at the correct

position.

Fault of Tool Carriage Connection

Loose of Connection Part

Fault of the Limit Position Initialize value

Limit Sensor does not work correctly or is

broken.

CAUSE

Servo Board does not work correctly.

Sub CPU does not work correctly.

There is a bad connection between Main

Board and Servo Board.

6-12

Limit Sensor does not work correctly or is

broken.

Tool Carriage is not located at the correct

position.

SRAM is broken.

Servo Board does not work correctly.

Sub CPU does not work correctly.

There is a bad connection between Main

Board and Servo Board.

A noise on a signal.

A noise on a signal while sending a

command.

Sub CPU was reset to default.

Tried to communicate when Sub CPU was

reset to default.

Servo Board does not work correctly.

Sub CPU does not work correctly.

There is a bad connection between Main

Board and Servo Board.

A noise on a signal while sending a

command.

Sub CPU was reset while sending a

command.

Servo Board does not work correctly.

Sub CPU does not work correctly.

There is a bad connection between Main

Board and Servo Board.

A noise on a signal.

Fault of Tool Carriage Connection

Loose of Connection Part

Fault of the Limit Position Initialize value

Limit Sensor does not work correctly or is

broken.

Содержание VS-300

Страница 49: ...2 4 MAIN BOARD_Arrangement Diagram Soldering Side ...

Страница 59: ...2 14 2 3 SERVO BOARD SERVO BOARD_Arrangement Diagram Component Side It indicates the version of the Board ...

Страница 60: ...2 15 SERVO BOARD_Arrangement Diagram Soldering Side ...

Страница 65: ...2 20 2 4 CARRIAGE BOARD CARRIAGE BOARD_Arrangement Diagram Component Side ...

Страница 68: ...2 23 2 5 SUB BOARD SUB BOARD_Arrangement Diagram Component Side ...

Страница 141: ...3 68 7 8 OFF Dispose of the battery Turn off the Sub Power SW and then turn off the Main Power SW Fix the Chassis Cover ...

Страница 257: ...4 59 22 Fix the Right Side Frame by sliding it from behind to hook the tab as shown in the fig ure ...

Страница 279: ...7 2 Unpacking Manual CD ROM DVD ROM etc ...