4-2

4-1 SERVICE MODE

This menu is used for entering the Head Rank for each head with 24 digit number and alphabet.

The digits can be changed with [ ] and [ ] keys and parameters can be changed with

[ ] and [ ] keys. The digit being changed is marked with an under bar.

Press [ENTER] key to save the settings. It beeps for alerting when the calculation for verification,

CHECK SUM, is not correct in order to avoid input error.

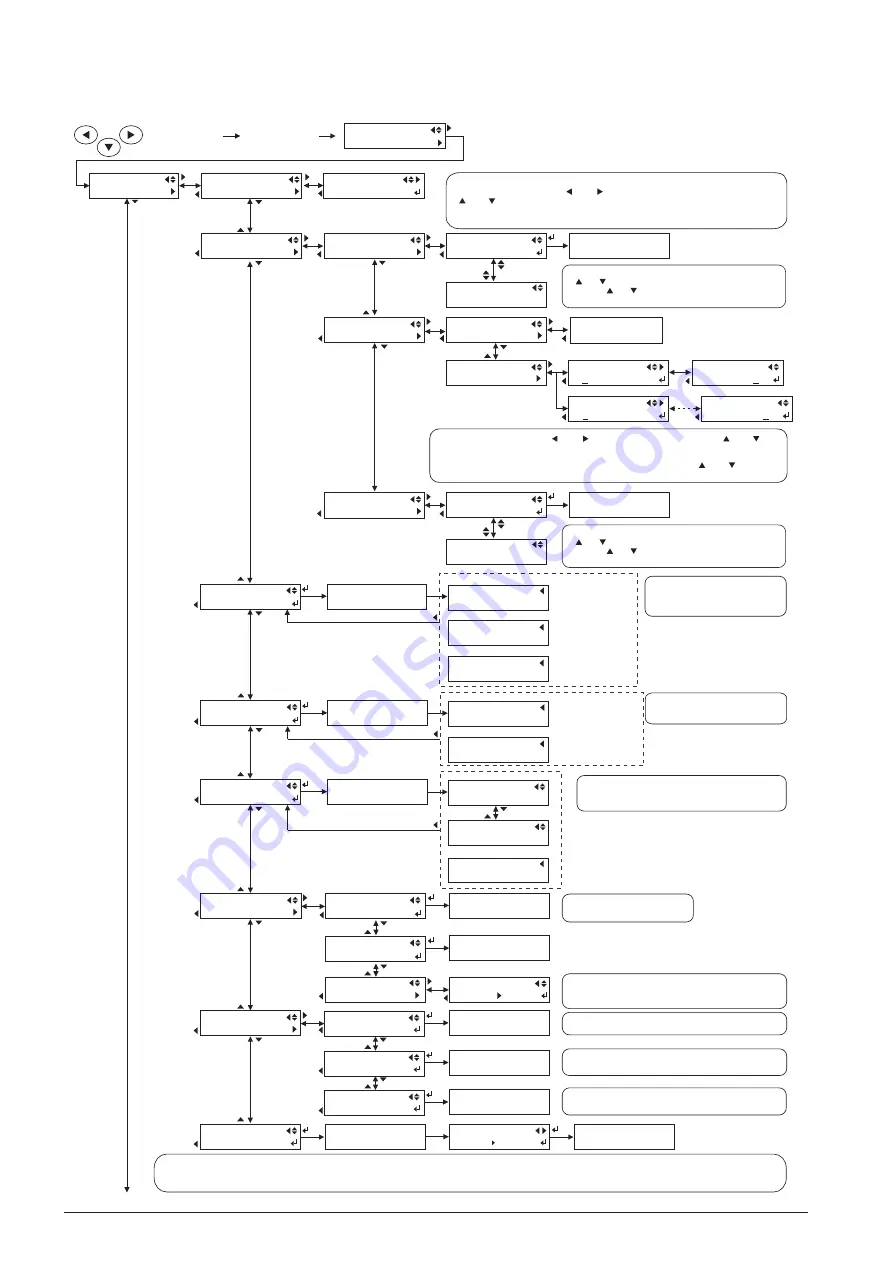

PRINT MENU

HEAD RANK

HEAD RANK

12345678 (1/3)

[ MENU ] key

SERVICE MENU

PRINT MENU

HEAD ADJUST

BI-DIR.DEFAULT

No.1 No.2

-15 -20

No.3 No.4

-15 -20

No.1 No.2

-15 -20

No.19 No.20

-15 -20

PRINT MENU

HEAD ADJUST

HEAD ADJUST

BIAS

BIAS

TEST PRINT

PERFORMING

BIAS

--- VIEW ---

BI-DIR.DEFAULT

SETTING

BI-DIR.DEFAULT

TEST PRINT

MENU

SERVICE MENU

Feeds media for visual check of the test pattern, by pressing

[ ] or [ ] keys while in [TEST PRINT] menu. Also by

pressing [ ] or [ ] keys again after feeding, media returns

to the original position.

PERFORMING

TEST PRINT

TEST PRINT

Dot pattern can be selected with [ ] and [ ] keys, and value can be selected with [ ] and [ ] keys.

[ENTER] key for saving the setting. The value being selected is marked with an under bar.

It returns to the former menu after setting.

Default:

(

0) It can be changed starting from the standard value (15) with [ ] and [ ] keys.

Range: 0 to +60dot (changeable by 0.5dot which is indicated as 1/2.

HEAD ADJUST

BIAS 2

BIAS 2

TEST PRINT

PERFORMING

BIAS

--- VIEW ---

Feeds media for visual check of the test pattern, by pressing

[ ] or [ ] keys while in [TEST PRINT] menu. Also by

pressing [ ] or [ ] keys again after feeding, media returns

to the original position.

TEST PRINT

* *

+ POWER ON

Ink type : PIGMENT

Ink type : MAX

PRINT MENU

CALIB.DEFAULT

CALIB.DEFAULT

TEST PRINT

CALIB.DEFAULT

SETTING

SETTING

+0.05% +0.10%

PRINT MENU

TEST PATTERN

TEST PATTERN

BI-DIR.

PRINT MENU

LINEAR ENCODER

NOW PROCESSING..

LINEAR ENCODER

SETUP COMPLETED

LINEAR ENCODER

SETUP FAILED

Normal (beeps 1 time)

Error (beeps 2 times)

This is for checking the installation and

operation of Linear Encoder and Scale.

Refer to [4-5 LINEAR ENCODER SETUP].

POS: 1361.00mm

PERFORMING

PERFORMING

PRINT MENU

LINEAR CALIB.

NOW PROCESSING..

LINEAR CALIB.

SETUP COMPLETED

LINEAR CALIB.

FAILED TO SETUP

TEST PATTERN

FILL

PERFORMING

TEST PATTERN

FLUSHING ADJ.

0.00mm -0.40mm

BI-DIR. CHECK

PERFORMING

PRINT MENU

FLUSHING ADJ.

NOW PROCESSING..

LINEAR CALIB.

0.18%

This menu is used for Calibration.

Refer to [4-10 CALIBRATION].

NOW PROCESSING..

TEST PRINT

TEST PRINT

TEST PRINT

TEST PRINT

Error is found on Linear

Encoder and Scale.

Normal (beeps 1 time)

Error (beeps 2 times)

This is for calibrating the cutting size in the scan direction

by calculating the expansion and contraction amount of the

Encoder Scale.

When it shows [ ], it means that it has never been setup and

it needs to be set. In this case, even if adjustment is unnecessary

by the test result, [0] must be set here.

This is for checking the Head Alignment in Bidirectional.

It prints on the entire print range with solid single color by each head.

Print mode is fixed at 720 dpi and 8 pass.

This print pattern is for checking a shifting error in Bidirectional and

also for confirming the mechanical tendency.

*****

LINEAR ENCODER

HEADBOARD FAILED

Error (beeps 2 times)

Error is found on Head

Board.

CALIB.DEFAULT

TEST PRINT2

PERFORMING

TEST PRINT

PRINT MENU

LINEAR CHECK

NOW PROCESSING..

LINEAR CHECK

COMPLETED

LINEAR CHECK

FAILED:1000.00mm

Normal (beeps 1 time)

Error (beeps 3 times)

This is for checking if there are dusts,

greases or scratches on Linear Encorder.

Dusts, greases or scratches

are found on Linear Scale.

This is for adjusting the flushing position. Set the head height to LOW. As entering the menu, the Head Carriage moves to the current flushing position.

With [left] and [right] keys, Move the Head Carriage to the position where the slot of the Carriage Cap Guide makes contact with the tip of the Backup Cap Base, and press [ENTER] key to save

the position. Or, start the adjustment from the leftmost position and press [ENTER] key to save the position where arm part of cap unit starts to move.

As [ENTER] key is pressed, the head is automatically capped and it backs out the menu. For backing out the menu without saving the position, press [MENU] key without pressing [ENTER] key.

Содержание VS-300

Страница 49: ...2 4 MAIN BOARD_Arrangement Diagram Soldering Side ...

Страница 59: ...2 14 2 3 SERVO BOARD SERVO BOARD_Arrangement Diagram Component Side It indicates the version of the Board ...

Страница 60: ...2 15 SERVO BOARD_Arrangement Diagram Soldering Side ...

Страница 65: ...2 20 2 4 CARRIAGE BOARD CARRIAGE BOARD_Arrangement Diagram Component Side ...

Страница 68: ...2 23 2 5 SUB BOARD SUB BOARD_Arrangement Diagram Component Side ...

Страница 141: ...3 68 7 8 OFF Dispose of the battery Turn off the Sub Power SW and then turn off the Main Power SW Fix the Chassis Cover ...

Страница 257: ...4 59 22 Fix the Right Side Frame by sliding it from behind to hook the tab as shown in the fig ure ...

Страница 279: ...7 2 Unpacking Manual CD ROM DVD ROM etc ...