35

Chapter 2 - Basic Operation

2-2 Loading Media

4

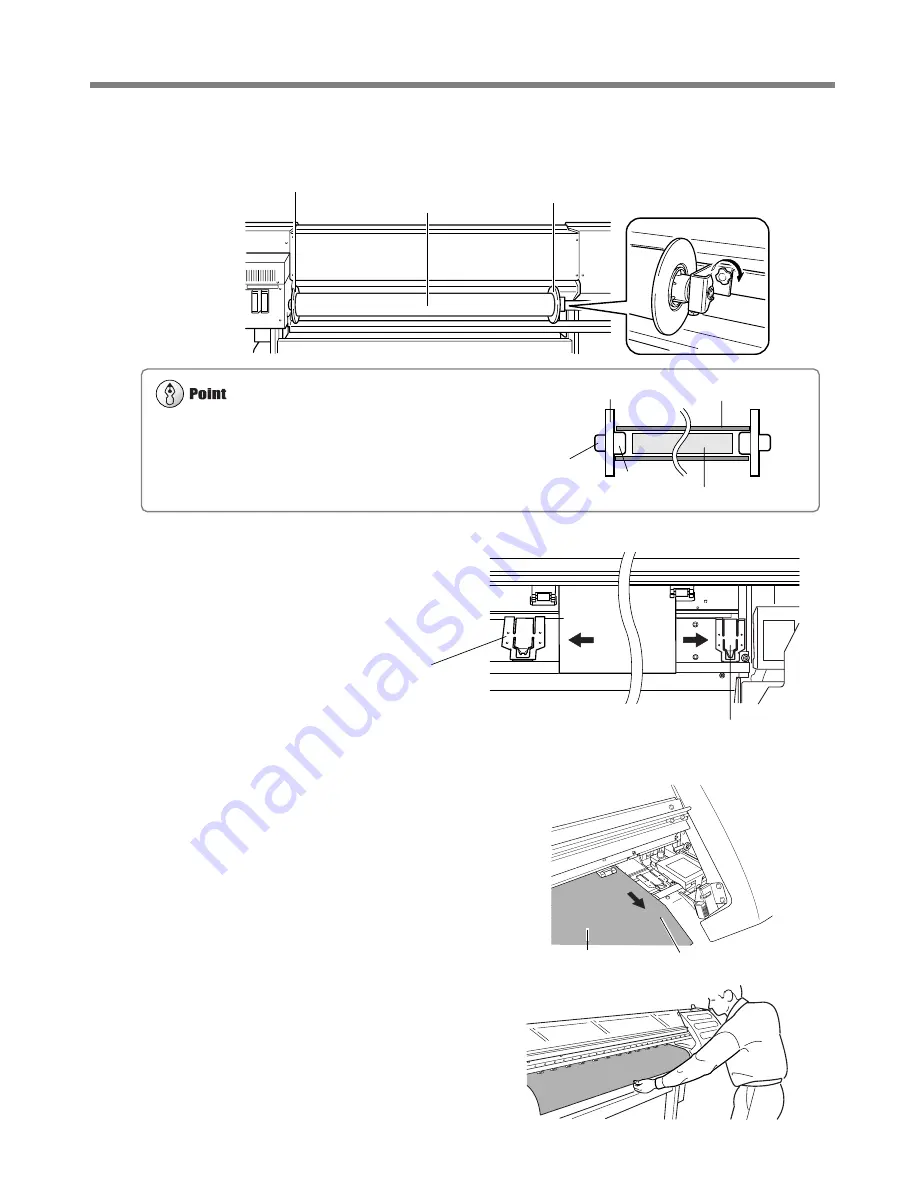

Fit the right-hand media flange all the way into the hole on the right-hand side of the roll media, and

tighten the retainer screw to secure in place.

5

Move the media clamps to the two ends of the platen.

6

Pass the end of the media from the back of the

machine to the front.

Pull out the media until the sensor is hidden

from view.

7

Grasp the center of the end of the media at the

front of the machine, and slowly pull the media

out straight to the position shown in the figure.

Media

Front

Sensor

Roll media

Media flange (left)

Media flange (right)

Media clamp

Media clamp

Reforcement pipe is included with SJ-740/640. When roll media sag severely,

use the reinforcement pipe inserted into the roll media. After use, remove the

reinforcement pipe from the paper tube.

Roll media

Media frange

2 in.

3 in.

Reinforcement pipe

Содержание SJ-540

Страница 63: ...61 4 Maintenance This section describes how to clean the printing heads daily care and maintenance and the like...

Страница 95: ...93 7 Appendix...

Страница 101: ......

Страница 102: ...R5 030905...