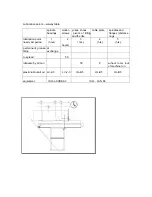

9.6 Adjusting of the cross-ruler

Adjusting of parallelism

Parallelism of lengthwise ruler (A) with

the saw blade (B) gets adjusted by

position change of the ruler carrying

bar with protrusion or insertion of

carrying bars (D) in place where the

ruler is fixed to the cast iron table. After

releasing of screws (C) and releasing

of fixing nuts it is possible to turn with

the distance bar and to screw it in or

out for a new dimension of distance. It

is necessary to fix the new position of

the bar by means of 2 nuts in the edge

of table extension.The ruler is adjusted

from the producer with a divergence to

the saw blade of cca 0,1 ÷ 0,2

mm/1000 mm.

adjusting of plumb:

The cross-ruler

(A) is placed at the supporting frame

(B) and its plumb to the saw blade gets

adjusted - after releasing of arresting

stars (C, D) and of arresting screw (F) -

by turning with the eccentric sprung

plunger (E)

. Do not forget to draw up

the arresting elements again after

adjusting the position.

Setting of sawing angle :

After

arresting stars (C and D) have been

released and the centring sprung pin

(E) has been pulled to the lower

position (it will remain in this position

after being turned slightly), the cross

ruler may be adjusted under the angle 0

o

÷45

o

according to scale (G). Do not forget to tighten

the arresting components again after the position has been adjusted.

Setting of backstops :

Backstops of cutting width (J) are adjustable after the arresting lever

has been released by being shifted in a groove of the cross ruler profile (A) while the value of

the width is being read on the scale. Do not forget to tighten the arresting components again

after the position has been adjusted.!

Setting of the zero position:

In the perpendicular direction of cross ruler (A) to the saw disc

its position is secured with sprung centring pin (E). If the cutting width set by the backstop

does not correspond to the reality (e.g. due to a change in the saw disc width), the

adjustment may be altered after releasing two arresting screws on the shim in the ruler

profile groove in the place of the sprung centring pin. Do not forget to tighten the arresting

components again after the position has been adjusted.

Supporting frame position:

Supporting frame (B) with cross ruler (A) may be shifted along

the supporting bar of the machine after arresting lever (H) has been released. Securing

callipers (I) prevent supporting frame (B) from falling off the supporting rod. The position of

cross ruler (A) may also be altered by its being moved to the other side of frame (B).

Содержание PF 400 S

Страница 1: ...DIMENSION SAW PF 400 S Service instructions updated 9 2002 ...

Страница 17: ...6 3 Installment of demountable parts ...

Страница 35: ......