43.

POSSIBLE CAUSE

CORRECTION

Loose motor or starter wiring.

Check all wiring terminals for contact and tightness.

7.4 EXCESSIVE LUBRICANT CONSUMPTION

POSSIBLE CAUSE

CORRECTION

Ruptured lubricant cooler.

Check cooler for leaks. Replace cooler, if required.

Leak in lubricant tubing and

connections.

Check for leaks and repair. See Section 4.0. Check for proper

lubricant.

Seal failure.

Replace seal. Check for proper lubricant. Contact your Rogers

factory representative.

Incorrect or contaminated lubricant.

Use recommended lubricants only. — See Section 4.0

Lubricant Carry-over

See “Excessive Lubricant Carry-over” see section 7.5.

Faulty or damaged separator element. Replace air/lubricant separator element per Section 4.7.

Leaks from lubricant filter gaskets.

Inspect and replace gasket as necessary. See Section 4.6.

Leaks from reservoir cover.

Inspect and replace gasket as necessary. See Section 4.7

7.5 EXCESSIVE LUBRICANT CARRY-OVER

POSSIBLE CAUSE

CORRECTION

Lubricant level too high in reservoir.

Lower lubricant level to recommended level by draining the

sump after depressurization. Check drainage for condensation.

Cycling between load and unload

excessively.

See “Excessive Cycling Between Load and Unload”, Section

7.11.

Plugged or broken scavenging lines.

Check scavenging system. Clean or replace as required.

Excessive lubricant foaming.

Water in lubricant. Change lubricant and/or increase operating

temperature.

Low reservoir pressure.

Reservoir pressure should not fall below 80 PSIG when

running loaded.

Improper adjustment of scavenging

line.

Adjust per Section 4.8

7.6 FREQUENT AIR / LUBRICANT SEPARATOR CLOGGING

POSSIBLE CAUSE

CORRECTION

Faulty air filter or inlet line.

Replace elements and/or air inlet connection.

Faulty lubricant filter or filter head.

Replace lubricant filter element. Inspect filter head for open

bypass.

Lubricant breakdown.

Change lubricant at prescribed intervals. Possible lubricant

contamination. Ensure lubricant sample is analyzed frequently.

See Section 4.0.

Contamination of lubricant.

Change lubricant and lubricant filter, and flush if necessary.

Check for contamination source. See Section 4.0.

Incorrect lubricant filter and/or

separator element.

Use Rogers’ replacement elements only. Do not attempt to

clean separator elements.

Emulsion forming in separator.

Operate compressor at recommended reservoir pressure and

lubricant injection temperature. Contact your Rogers factory

representative.

Mixing different grades or types of

lubricant.

DO NOT MIX DIFFERENT GRADES OR TYPES OF

LUBRICANT. DO NOT MIX LUBRICANTS OF DIFFERENT

MANUFACTURERS.

Содержание KI Series

Страница 1: ...1 Model __________________ Serial __________________ Rotary Screw Air Compressors...

Страница 8: ...7 INTENTIONALLY BLANK...

Страница 9: ...8 CHAPTER 1 GENERAL INFORMATION...

Страница 19: ...10 CHAPTER 2 INSTALLATION INSTRUCTIONS...

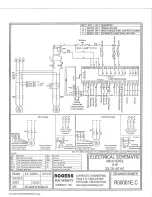

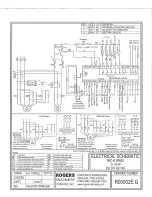

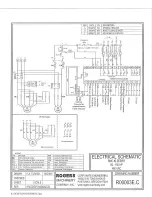

Страница 26: ...17 CHAPTER 3 ELECTRICAL INFORMATION...

Страница 30: ...21 CHAPTER 4 COMPRESSOR LUBRICANT...

Страница 39: ...30 INTENTIONALLY BLANK...

Страница 40: ...31 CHAPTER 5 AIR INLET FILTER INFORMATION...

Страница 43: ...34 INTENTIONALLY BLANK...

Страница 44: ...35 CHAPTER 6 COMPRESSOR OPERATIONS...

Страница 49: ...40 INTENTIONALLY BLANK...

Страница 50: ...41 CHAPTER 7 TROUBLESHOOTING...

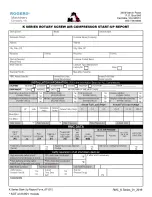

Страница 57: ...48 CHAPTER 8 FORMS RECORDS AND ELECTRICAL SCHEMATICS...

Страница 58: ...49...

Страница 59: ...50...

Страница 60: ...51...

Страница 61: ...52...

Страница 62: ...53...

Страница 63: ...54...

Страница 64: ...55...

Страница 65: ...56 INTENTIONALLY BLANK...

Страница 66: ...57...