Содержание KI Series

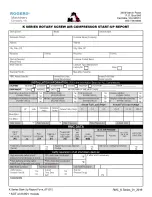

Страница 1: ...1 Model __________________ Serial __________________ Rotary Screw Air Compressors...

Страница 8: ...7 INTENTIONALLY BLANK...

Страница 9: ...8 CHAPTER 1 GENERAL INFORMATION...

Страница 19: ...10 CHAPTER 2 INSTALLATION INSTRUCTIONS...

Страница 26: ...17 CHAPTER 3 ELECTRICAL INFORMATION...

Страница 30: ...21 CHAPTER 4 COMPRESSOR LUBRICANT...

Страница 39: ...30 INTENTIONALLY BLANK...

Страница 40: ...31 CHAPTER 5 AIR INLET FILTER INFORMATION...

Страница 43: ...34 INTENTIONALLY BLANK...

Страница 44: ...35 CHAPTER 6 COMPRESSOR OPERATIONS...

Страница 49: ...40 INTENTIONALLY BLANK...

Страница 50: ...41 CHAPTER 7 TROUBLESHOOTING...

Страница 57: ...48 CHAPTER 8 FORMS RECORDS AND ELECTRICAL SCHEMATICS...

Страница 58: ...49...

Страница 59: ...50...

Страница 60: ...51...

Страница 61: ...52...

Страница 62: ...53...

Страница 63: ...54...

Страница 64: ...55...

Страница 65: ...56 INTENTIONALLY BLANK...

Страница 66: ...57...