7.

1.5

Description of Air and Lubricant Separator System

1.5.1

Air / Lubricant Separator Reservoir

The air / lubricant separator reservoir is an ASME coded pressure vessel which serves as a fluid reservoir

and provides mechanical separation of the lubricant and air. The air / lubricant reservoir should not be

welded on or modified in any way.

The discharge line from the compressor enters the reservoir above the lubricant level. A lubricant level

gauge is provided in the reservoir as a visual means to observe lubricant level during operation. An

ASME rated safety relief valve is located on the "wet" side before the lubricant separator element to

prevent the ASME rated separator tank from being over pressurized.

This is the “safety of last resort” and should not be used to control the air compressor. If this valve opens

to vent pressure, shut the compressor down and investigate the cause.

1.5.2

Separator Element, 10 and 15 HP

KI and KIV 10 through 20 HP units utilize an external spin-on separator element which is mounted

immediately downstream of the separator tank. Bulk lubricant separation occurs in the separator reservoir

mechanically and by gravity before coalescing filtration removes oil vapor from the air in the separator

element media. A scavenging tube returns separated lubricant to a low pressure area of the compressor.

See Figure 2.

1.5.3

Separator Element, 25 to 100 HP

KI and KIV 25 through 100 HP units are equipped with an internal separator element often referred to as

a “Top Hat” style separator system. The lubricant separator reservoir contains an air/lubricant separator

element beneath the tank’s lid. As air/lubricant mixture enters the reservoir, most of the lubricant

separates from the air and falls toward the bottom of the reservoir.

As the air passes through the lubricant separator element, lubricant coalesces on the separator element.

The lubricant which collects on the outside of the filter element drips into the bottom of the lubricant

reservoir. The lubricant that migrates to the inside of the separator element drains by gravity to the bottom

of the inside of the element where it is siphoned off via the scavenging return tube to a low pressure area

of the compressor. See Figure 3.

The minimum operating pressure on a standard machine is 80 PSIG. Operating below this pressure may

cause excessive carry-over of lubricant through the lubricant separator and high lubricant consumption

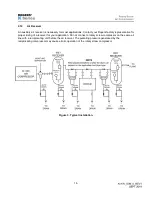

1.6

Description of Standard Capacity Control System

CAUTION

Care must be taken when working on or removing the inlet on a KI or KIV compressor to

prevent loose parts from being inadvertently dropped into the compressor inlet during

inspection and repair.

The KI and KIV series of air compressors (10 – 100 HP) use four (4) different inlet valves. Refer to the

Description of Operation, Display and Controls manual for detailed information about your compressor

capacity control system. The information in section 1.6 is general in nature.

The inlet valve is a combination modulating valve/check valve. Regardless of control pressure or valve

position, the valve fully closes on shutdown. This action limits back spinning and stops lubricant flow.

Содержание KI Series

Страница 1: ...1 Model __________________ Serial __________________ Rotary Screw Air Compressors...

Страница 8: ...7 INTENTIONALLY BLANK...

Страница 9: ...8 CHAPTER 1 GENERAL INFORMATION...

Страница 19: ...10 CHAPTER 2 INSTALLATION INSTRUCTIONS...

Страница 26: ...17 CHAPTER 3 ELECTRICAL INFORMATION...

Страница 30: ...21 CHAPTER 4 COMPRESSOR LUBRICANT...

Страница 39: ...30 INTENTIONALLY BLANK...

Страница 40: ...31 CHAPTER 5 AIR INLET FILTER INFORMATION...

Страница 43: ...34 INTENTIONALLY BLANK...

Страница 44: ...35 CHAPTER 6 COMPRESSOR OPERATIONS...

Страница 49: ...40 INTENTIONALLY BLANK...

Страница 50: ...41 CHAPTER 7 TROUBLESHOOTING...

Страница 57: ...48 CHAPTER 8 FORMS RECORDS AND ELECTRICAL SCHEMATICS...

Страница 58: ...49...

Страница 59: ...50...

Страница 60: ...51...

Страница 61: ...52...

Страница 62: ...53...

Страница 63: ...54...

Страница 64: ...55...

Страница 65: ...56 INTENTIONALLY BLANK...

Страница 66: ...57...