37.

1. Start compressor; look for excessive vibration, lubricant leaks, proper operating temperatures

and pressures.

2. Observe operating temperature until stabilized. If the air temperature continues to rise above

180 °F (*82 °C), shut down the compressor and investigate the cause.

3. Maximum pressure is limited by available power. Do not exceed motor name plate rating for

service factor amps or safety valve setting.

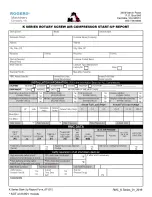

4. Completely fill out the daily record card (example shown in Addendum 1). Be sure to take

voltage and amperage readings at constant pressure and with the compressor loaded. A

separate start-up form is provided with each new air compressor. The form needs to be

completely filled out and sent back to the factory for warranty purposes.

5. Test high temperature safety shutdown for proper operation by lowering the trip setting in the

CDP controller until the compressor shuts down. Compare the CDP setting with the oil

temperature. They should be similar values.

6. Another method for testing the high temperature shut down would be to raise the fan

temperature turn on set point to 237 °F (114 °C). The fan will not start until this temperature is

reached. If the high temperature shut down is working properly the compressor will shut down at

235 °F (113 °C). RESET THE FAN TEMPERATURE TURN ON SET POINT BACK TO

FACTORY SETTINGS (60 °F (16 °C)).

6.2

Starting Unit (After Initial Start Up)

1. Ensure lubricant is present in lubricant sight tube.

2. Press start button.

3. Watch operating temperature while unit pressure rises.

4. Observe operating parameters, check readings against normal operating ranges.

5. Check for lubricant leaks.

6. Make notations on Daily Record Card as indicated.

7. KI and KIV units are equipped with a restart delay initially set at 30 seconds. The unit will

not restart until this timer has counted down to zero after the previous stop.

6.3

Stopping Unit (Normal Shut Down)

1. Press stop button on the controller. The blow-down valve will automatically depressurize the

reservoir. The machine will continue to run for a pre-determined time (stop delay – initially set at

45 seconds) to stabilize unloaded operation before it shuts down the main motor. Once stopped

the restart delay counter will begin its countdown. The unit cannot start until this counter has

reached zero.

2. Do not use the Emergency Stop Button to shut the unit down under normal conditions. The

Emergency Stop Button is intended for use during emergency only. Emergency Stop is a harsh

and abrupt stop. While intermittent use of this feature should not significantly damage the

compressor, repeated use increases the risk of damage to the compressor.

Содержание KI Series

Страница 1: ...1 Model __________________ Serial __________________ Rotary Screw Air Compressors...

Страница 8: ...7 INTENTIONALLY BLANK...

Страница 9: ...8 CHAPTER 1 GENERAL INFORMATION...

Страница 19: ...10 CHAPTER 2 INSTALLATION INSTRUCTIONS...

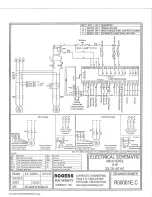

Страница 26: ...17 CHAPTER 3 ELECTRICAL INFORMATION...

Страница 30: ...21 CHAPTER 4 COMPRESSOR LUBRICANT...

Страница 39: ...30 INTENTIONALLY BLANK...

Страница 40: ...31 CHAPTER 5 AIR INLET FILTER INFORMATION...

Страница 43: ...34 INTENTIONALLY BLANK...

Страница 44: ...35 CHAPTER 6 COMPRESSOR OPERATIONS...

Страница 49: ...40 INTENTIONALLY BLANK...

Страница 50: ...41 CHAPTER 7 TROUBLESHOOTING...

Страница 57: ...48 CHAPTER 8 FORMS RECORDS AND ELECTRICAL SCHEMATICS...

Страница 58: ...49...

Страница 59: ...50...

Страница 60: ...51...

Страница 61: ...52...

Страница 62: ...53...

Страница 63: ...54...

Страница 64: ...55...

Страница 65: ...56 INTENTIONALLY BLANK...

Страница 66: ...57...