9

1.4. Oil Flow for Lubrication

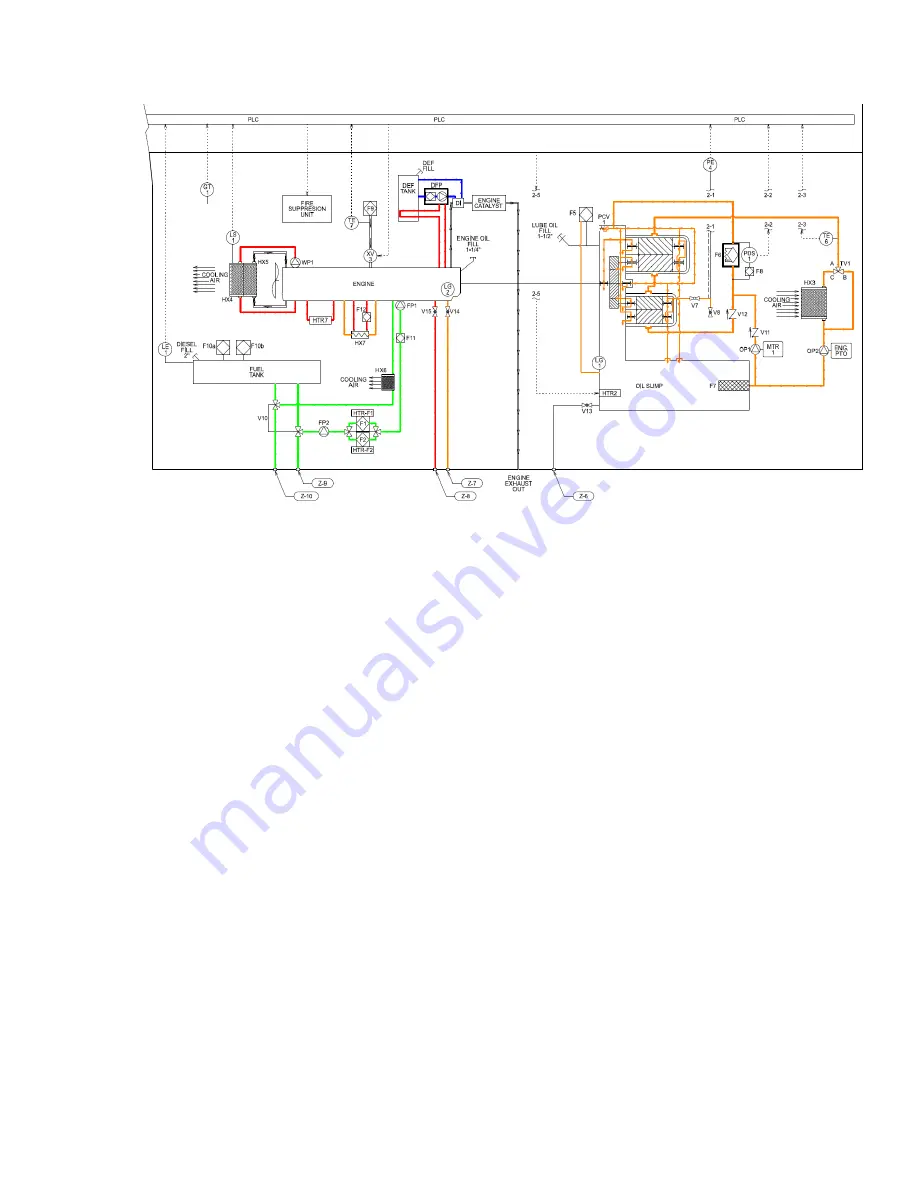

FIGURE 3 - OIL FLOW

Oil for bearing and gear lubrication is stored in the oil sump, located in the lower section

of the main gear case/compressor housing. A sight gauge, located on the side of the oil

sump, is provided to check oil level. Lube oil is drawn from the sump by a separate

motor-driven oil pump (OP1) during start-up, then transitions to be run by a PTO-driven

pump after the Diesel engine starts. A check valve on the outlet of the electric oil pump,

and upstream of the oil filter prevents backflow. A strainer (F7) is provided in the oil

sump on the oil pump suction line.

An oil thermostatic valve (TV1) and air-cooled oil cooler (HX3) control oil temperature to

approximately 115°F (45°C). Cooled oil enters the compressor 1st stage cooling jacket

then the 2nd stage cooling jacket. The oil is then filtered by a high efficiency microglass

oil filter, featuring a full flow design incorporating a spin-on filter element and an internal

relief valve. A differential pressure gauge with switch (PDS1) is used to check oil filter

Δ

P

and generate an HMI alert to service the oil filter.

After filtration the oil enters the compressor oil passages. An oil pressure control valve

(PCV1) is provided to regulate a constant pressure for component lubrication by

returning excess oil back to the sump. The oil flows through internal passages, and

external tubing, to lubricate all bearings, timing gears, and drive gears.

An oil pressure transmitter (2-1) is wired to the PLC to monitor the lube oil pressure. Oil

pressure is monitored for alarm shutdown if oil pressure can not be achieved during

starting or is too low while the compressor is operating. A block valve (V7) and sample

valve (V8) are provided to test the operation of the alarm.

Содержание GPKD-1550-H

Страница 2: ...2 THIS PAGE LEFT BLANK...

Страница 22: ...22 Note The design of the oil pan is not the extended type as shown in the diagram FIGURE 10b ENGINE RIGHT SIDE...

Страница 47: ...47...

Страница 48: ...48 THIS PAGE LEFT BLANK...