44

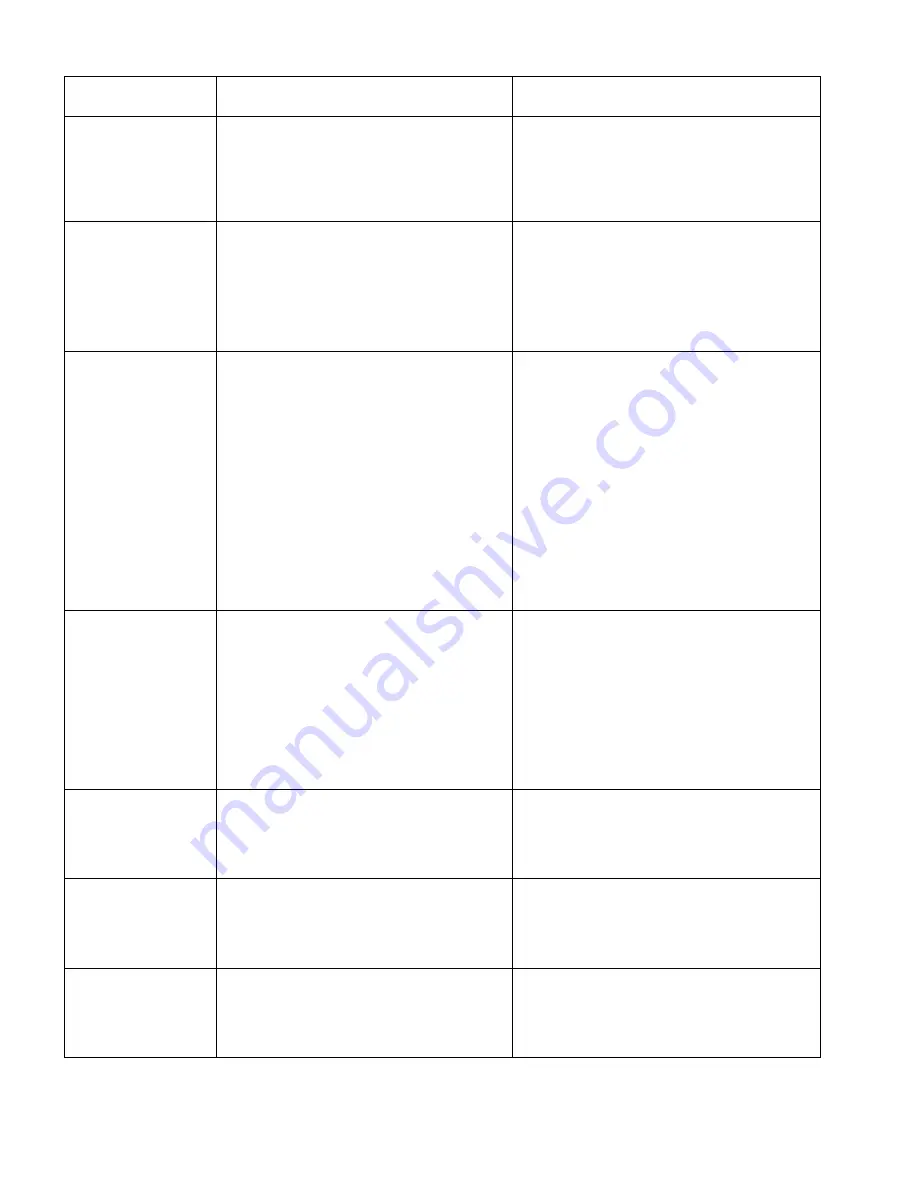

CONDITION

POSSIBLE CAUSE

SUGGESTED REMEDY

High compressor

outlet air temp.

1. Dirty aftercooler core.

2. Obstructed cooling air flow.

3. High ambient temperature.

1. Clean aftercooler (see section 6.4).

2. Check for and remove any foreign material

blocking air flow.

3. See High Inlet Air Temperature.

High oil

temperature

1. Oil level too high.

2. Dirty oil cooler core.

3. Gearcase sump breather element

plugged.

4. Obstructed cooling air flow.

1. Lower oil level to center of sight gauge.

2. Clean oil cooler (see section 6.4).

3. Replace element.

4. Check for and remove any foreign material

blocking air flow.

Failure to load.

1. 4-way solenoid valve defective.

2. Capacity Control Valve diaphragm

ruptured.

3. Capacity Control Valve bushings

defective.

4. Trouble with pressure transmitters.

5. Manual unload selected.

6. PLC Control not sending signal to

unloading valve.

7. Unloading valve relay defective.

8. Ruptured shuttle valve diaphragm.

1. Repair or replace unloading valve.

2. Replace diaphragm.

3. Repair Capacity Control Valve.

4. Check transmitter connections and wiring.

5. Press load button.

6. Check output to unloading valve relay for

voltage.

7. Replace unloading valve relay.

8. Rebuild or replace shuttle valve.

Air leaking from

bleed-off

silencer when

loaded.

1. Capacity Control Valve bushings

defective.

2. Damaged bleed-off valve disc.

3. Leak in control tubing.

4. Leaking diaphragm in shuttle valve.

5. Leaking diaphragm in CCV.

6. 4-way solenoid valve defective.

1. Repair Capacity Control Valve.

2. Install new bleed-off valve disc.

3. Check for and repair tubing leaks.

4. Replace shuttle valve.

5. Rebuild CCV.

6. Replace 4-way solenoid valve.

Abnormal noise

from compressor

element.

1. Coupling problems.

2. Gear trouble

3. Bearing trouble.

1. Inspect and repair coupling.

2. Overhaul gear assembly.

3. Replace affected stage.

Abnormal noise

from oil pump.

1. Oil level too low.

2. Defective pump.

3. Damaged coupling.

1. Add oil to recommended level.

2. Replace pump.

3. Replace coupling.

Abnormal noise

from capacity

control valve

when loading.

1. Bushings worn in capacity control valve.

2. 4-way solenoid valve trouble.

3. Control tubing leaks.

1. Rebuild valve.

2. Replace 4-way solenoid valve.

3. Check tubing and correct faults.

Содержание GPKD-1550-H

Страница 2: ...2 THIS PAGE LEFT BLANK...

Страница 22: ...22 Note The design of the oil pan is not the extended type as shown in the diagram FIGURE 10b ENGINE RIGHT SIDE...

Страница 47: ...47...

Страница 48: ...48 THIS PAGE LEFT BLANK...